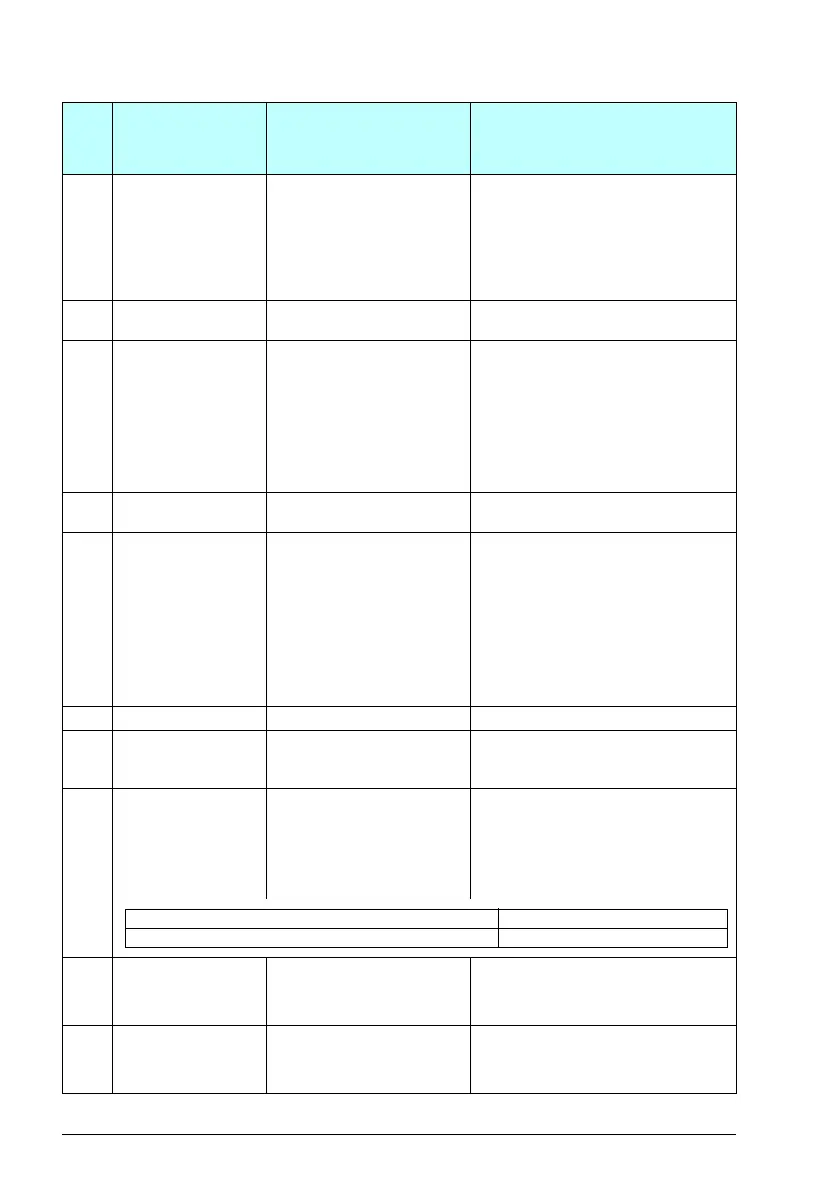

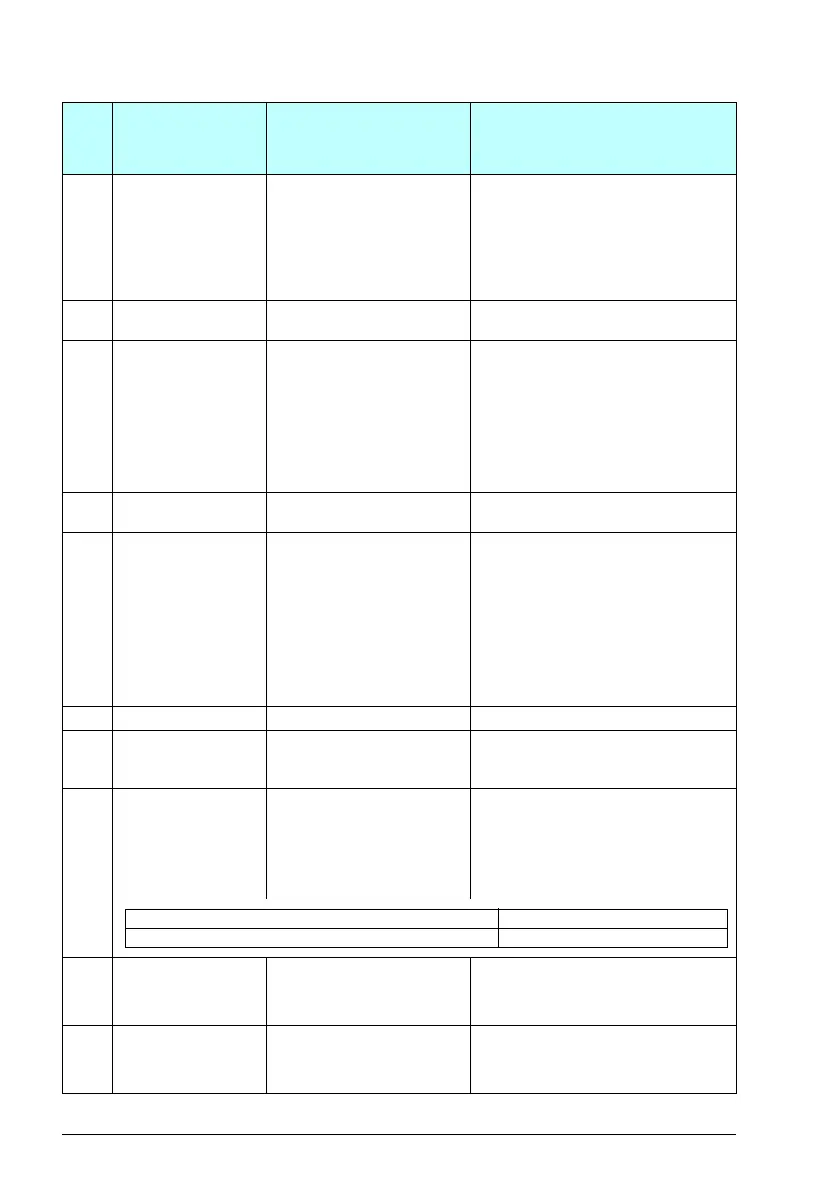

216 Fault tracing

7310 Overspeed Motor is turning faster than

highest allowed speed due to

incorrectly set

minimum/maximum speed,

insufficient braking torque or

changes in load when using

torque reference.

Check minimum/maximum speed

settings, parameters 30.11 Minimum

speed and 30.12 Maximum speed.

Check adequacy of motor braking torque.

Check applicability of torque control.

Check need for brake chopper and

resistor(s).

73F0 Overfrequency Maximum allowed output

frequency exceeded.

Check the auxiliary code.

00FA Motor is turning faster than the

highest allowed frequency due

to incorrectly set

minimum/maximum frequency

or the motor rushes because of

too high supply voltage or

incorrect supply voltage

selection in parameter 95.01

Supply voltage.

Check minimum/maximum frequency

settings, parameters 30.13 Minimum

frequency and 30.14 Maximum

frequency.

Check used supply voltage and voltage

selection parameter 95.01 Supply

voltage.

Other - Contact your local ABB representative,

quoting the auxiliary code.

7510 FBA A communication

Programmable fault: 50.02

FBA A comm loss func

Cyclical communication

between drive and fieldbus

adapter module A or between

PLC and fieldbus adapter

module A is lost.

Check status of fieldbus communication.

See user documentation of fieldbus

interface.

Check settings of parameter groups 50

Fieldbus adapter (FBA), 51 FBA A

settings, 52 FBA A data in and 53 FBA A

data out.

Check cable connections.

Check if communication master is able to

communicate.

8000 Unicos system error System fault. Power cycle.

8009 Current limit Motor actual current exceeded

the limit defined in parameter

30.17 Maximum current.

Reduce the motor load. Check for any

jam or stall in motor.

See parameter 30.17 Maximum current.

80A0 AI supervision

Programmable fault:

12.03 AI supervision

function

An analog signal is outside the

limits specified for the analog

input

Check signal level at the analog input.

Check the auxiliary code.

Check the wiring connected to the input.

Check the minimum and maximum limits

of the input in parameter group 12

Standard AI.

80B0 Signal supervision 1

(Editable message text)

Programmable fault:

32.06 Supervision 1 action

Fault generated by the signal

supervision function 1.

Check the source of the fault (parameter

32.07 Supervision 1 signal).

80B1 Signal supervision 2

(Editable message text)

Programmable fault:

32.16 Supervision 2 action

Fault generated by the signal

supervision function 2.

Check the source of the fault (parameter

32.17 Supervision 2 signal).

Code

(hex)

Fault / Aux. code (aux

code visible only on

assistant control panel

and drive composer)

Cause What to do

1 – AI1LessMIN 3 – AI2LessMIN

2 – AI1GreaterMAX 4 – AI2GreaterMAX

ACQ80 FW.book Page 216 Thursday, February 14, 2019 11:33 AM

Loading...

Loading...