6.2.5.1 Status

The following descriptive status and definitions are applicable for only the stream

test and are in addition to those defined for all start-up diagnostics.

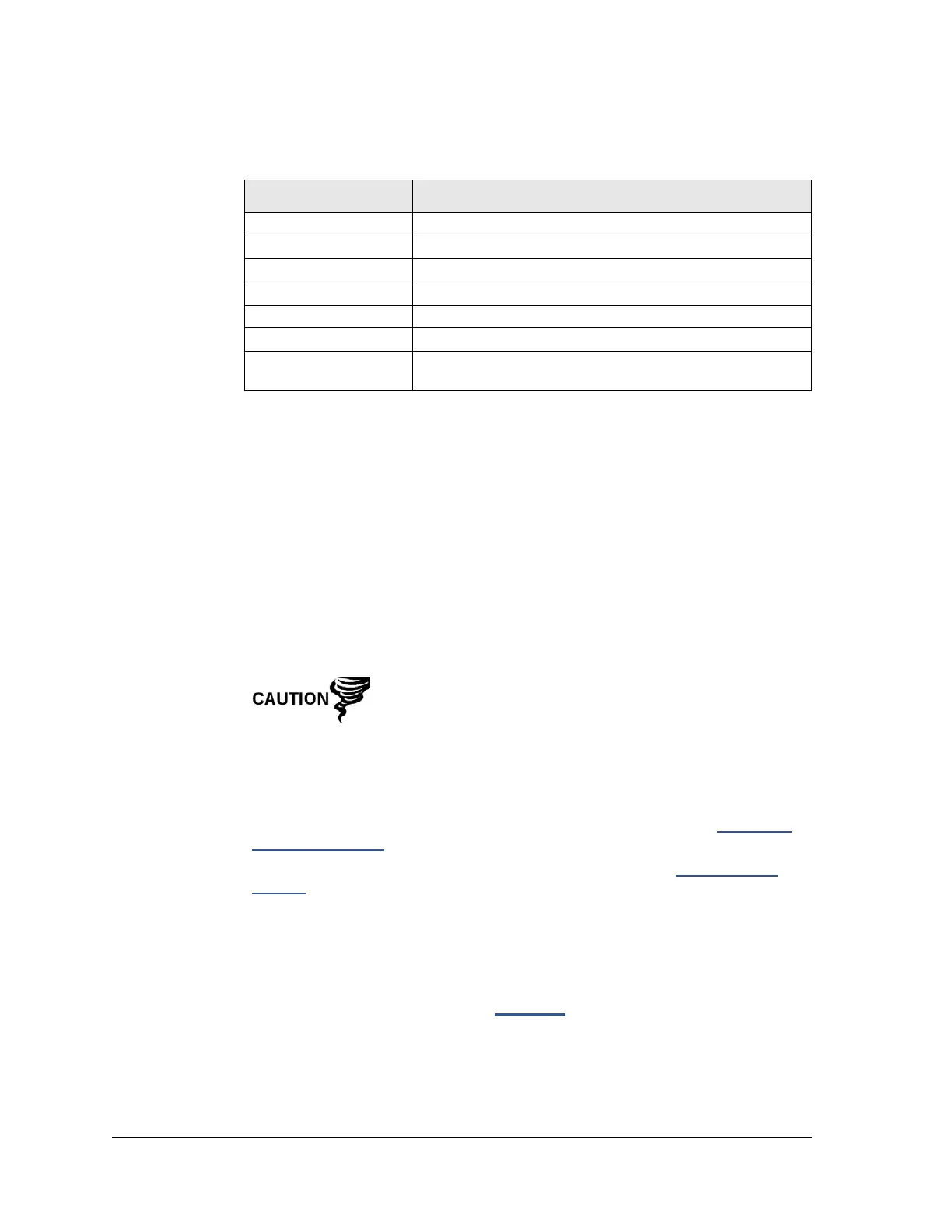

Status Description

Failed Initial Pressure Failed the Initial Pressure test.

Failed Resting Pressure Failed the Resting Pressure test.

Failed No Pressure Failed the Maximum Pressure test.

Failed Holding Pressure Failed the Holding Pressure test.

Failed Flowing Pressure Failed the Flowing Pressure test.

Failed Ending Pressure Failed the Ending Pressure test.

Waiting

This will be displayed by streams waiting to be tested. The

tests are run sequentially.

6.2.5.2 Description

These alarms are indicative of a sample pressure problem. The causes range

from a plugged frit filter to a bad GC module.

6.2.5.3 Instructions

1) Perform the sample vent pressure test procedure, found in this chapter, for the

sample vent. If the test failed, proceed to the next step.

2) Perform the feed-through assembly blockage test on the sample vent (SV). If the

test fails, replace the feed-through assembly with new or refurbished assembly.

Otherwise, continue to the next step.

Totalflow recommends that a replacement analytical module

be installed at this point and additional steps be performed in

a clean, lint free atmosphere. Because the customer does not

have the required equipment to determine which specific

module needs replaced, the final instructions are by process

of elimination, beginning with the most likely module.

The Totalflow repair department offers a range of services for

troubleshooting and repairing/replacing the non-functioning

parts. For more information regarding the repair service,

contact customer service:

USA: (800) 442-3097 or International: 1-918-338-4880

3) Using the Analytical Module Assembly instructions in Maintenance,

Replacing

Analytical Module assembly.

4) Using the Replacing GC Module instructions in Maintenance, Replacing GC

Module.

6.3 Troubleshooting Alarms

This section focuses on determining what has caused an alarm following normal

operation. The Totalflow

®

NGC8200 has an extensive built-in list of alarms, some

of which are user-configurable. These alarms may be grouped into three areas:

warning, fault and system fault. See Table 6–1

for a list of all enabled alarms. To

view all the available alarms, select Setup under Stream 1 on the Analyzer

Operation screen and select Alarm Definitions.

Loading...

Loading...