Loading...

Loading...

Do you have a question about the ABB TPL73-B12 and is the answer not in the manual?

| Brand | ABB |

|---|---|

| Model | TPL73-B12 |

| Category | Industrial Equipment |

| Language | English |

Explains the manual's objective for familiarizing users with the turbocharger for safe and efficient operation.

Describes the main components and overall layout of the turbocharger, including their functions.

Details the turbocharger's design purpose, operating limits, and safety compliance.

Provides guidelines for storing new turbochargers and spare parts, including VCI protection.

Covers organizational measures, safety checks, and modifications concerning the turbocharger.

Explains symbols, notes, and definitions used throughout the manual for clarity.

Details the information found on the turbocharger rating plate and its significance.

Provides contact details for ABB Turbo Systems service stations and website.

Highlights residual risks in turbocharger operation and the importance of safety instructions.

States that ABB turbochargers comply with EU Machinery Directive 2006/42/EC.

Explains the meaning and requirement of various mandatory safety signs.

Clarifies the meaning of WARNING and CAUTION symbols and their importance.

Describes the warning plates attached to the turbocharger and their required presence.

Details safety rules for personnel and work area during operation and maintenance.

Identifies mechanical, noise, and thermal hazards associated with turbocharger use.

Covers safety regulations and responsibilities for periodic checks of pressure vessels.

Provides safety guidelines and precautions for lifting turbocharger components.

Explains the importance of a proper oil supply system and filtration requirements.

Details visual checks, monitoring, and measurements required before and during commissioning.

Outlines the steps for recommissioning a turbocharger after it has been taken out of operation.

Discusses noise levels, potential hearing damage, and necessary ear protection.

Specifies the permissible range for the air inlet temperature for proper operation.

Covers regular maintenance tasks, service intervals, and inspections to ensure performance.

Provides guide values for component replacement intervals based on operating conditions.

Explains the speed measuring system, its components, and troubleshooting.

Details how to use a U-tube manometer to measure negative pressure at the filter silencer.

Describes conditions and precautions for operating the turbocharger without an emergency oil supply.

Explains the operation of flexible cut-out systems for turbochargers on multi-turbo engines.

Provides instructions on the proper procedure for stopping the engine and turbocharger.

Introduces maintenance activities, emphasizing visual checks and safety precautions.

Details the procedure for removing, cleaning, and fitting the filter silencer.

Explains the process for replacing the filter strip in the silencer casing.

Describes wet and dry cleaning methods for the compressor stage during operation.

Covers methods for cleaning turbine blades and nozzle rings during operation.

Lists possible causes and solutions for issues encountered during turbocharger start-up.

Explains the phenomenon of turbocharger surging and its potential causes and damage.

Addresses various operational malfunctions like low oil pressure, speed changes, and high exhaust gas temperature.

Covers issues related to noises during run-down and short run-down times.

Troubleshoots common problems with the turbocharger speed measurement system.

Provides weight specifications for different turbocharger models for lifting purposes.

Details the step-by-step procedure for safely removing the turbocharger from the engine.

Outlines the procedure for safely installing the turbocharger onto the engine.

Provides general safety precautions and identifies required assembly devices.

Lists the weights of individual turbocharger parts and assemblies for reference.

Describes the assembly and disassembly procedures for the turbocharger silencer casing.

Details the process for removing and reinstalling the filter silencer assembly.

Explains how to measure and check the axial clearance of the compressor wheel.

Provides instructions for safely removing the turbocharger's cartridge group.

Guides on inspecting and assessing the condition of the valve block.

Describes the procedures for dismantling and installing the turbine diffuser and nozzle ring.

Details the steps for correctly installing the turbocharger's cartridge group.

Explains the process for removing and fitting the nozzle ring at the turbine end.

Describes the assembly of the dry-cleaning device for turbocharger maintenance.

Provides a comprehensive table of tightening torques for various turbocharger components.

Outlines emergency repair options and fire/explosion risks due to oil leaks.

Explains procedures and precautions for locking the turbocharger rotor.

Provides instructions for shutting off inlets and outlets, referring to engine manufacturer's instructions.

Details the process for bypassing the turbocharger, referring to engine manufacturer's instructions.

Describes how to fit a cover plate, including material specifications and instructions.

Covers mothballing measures and conditions for engines taken out of operation for up to 12 months.

Provides guidance on preserving the turbocharger for extended periods of engine inactivity.

Specifies the data required for ordering spare parts and storage guidelines.

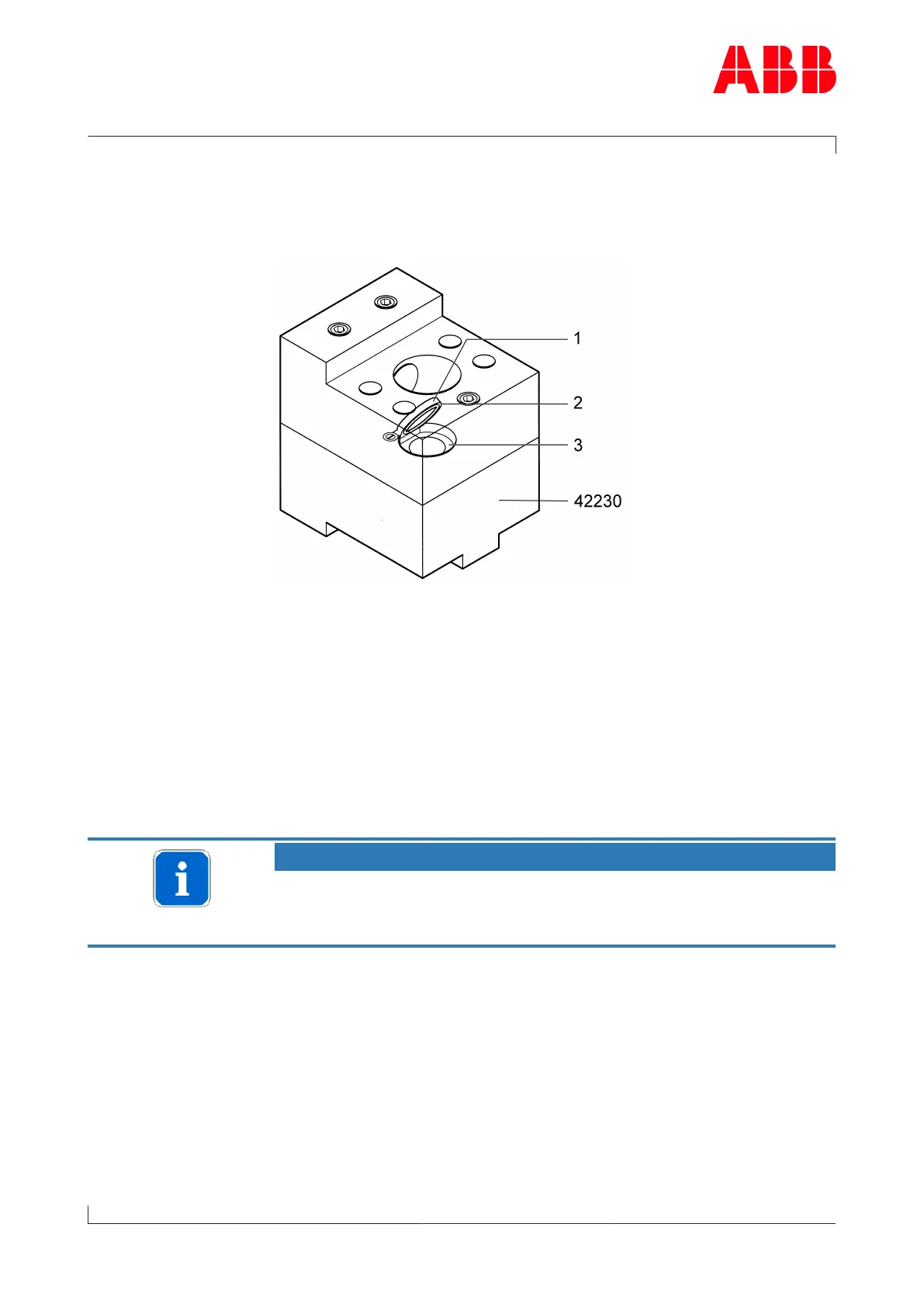

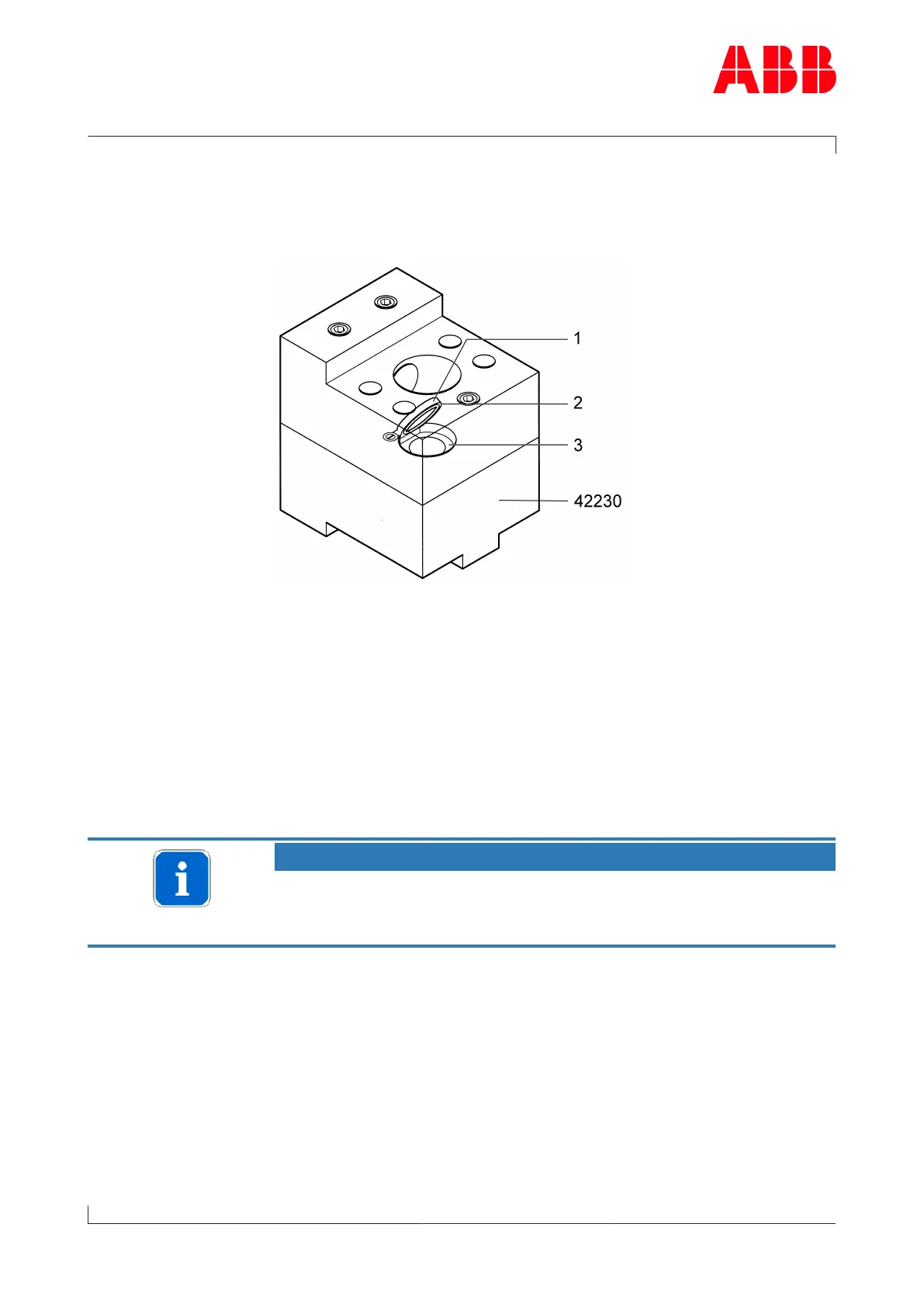

Illustrates the turbocharger with numbered parts for identification.

Shows the cartridge group with numbered components for part identification.