Programming and Parameters 3-49

Enhanced Program Group

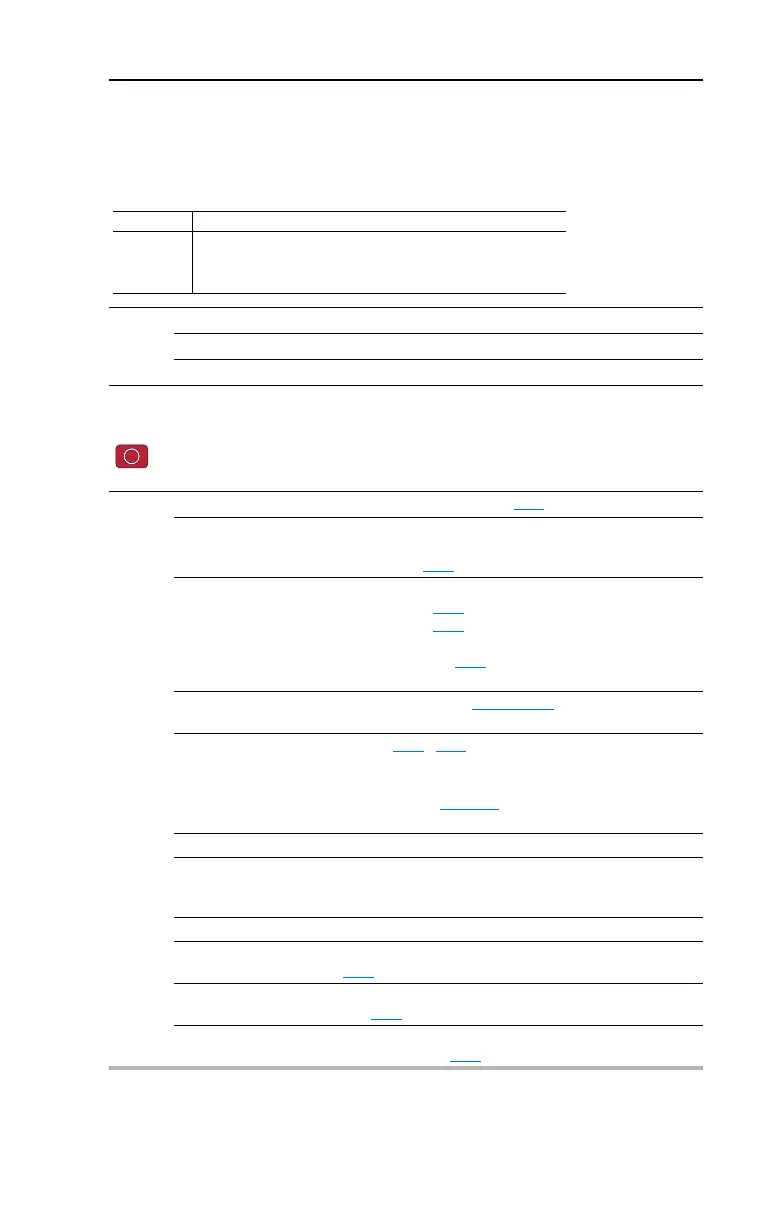

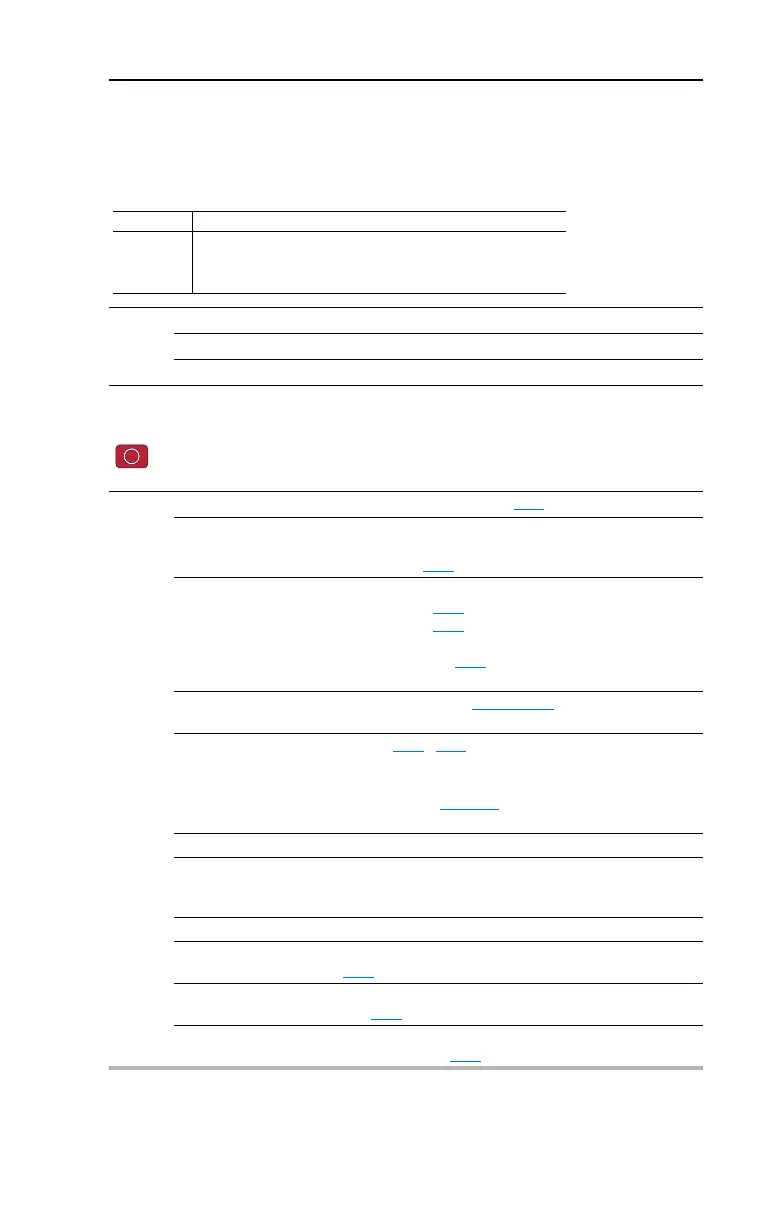

E201 [LED Display Opt]

Selects which parameters can be viewed by the drive’s LED interface.

Values Default: 2

Min/Max: 0/3

Display: 1

E201 Option Parameter Set

0

1

2

3

All Basic Display (Group b) and Advanced Display (Group d) parameters

All Basic Display Group (b001-b029) parameters

Basic Display Group parameters b001-b007 and b010

Basic Display Group parameter b001-b004

E202 [Digital Term 3]

Stop drive before changing this parameter.

Sets the function of I/O Terminal 03.

Options 0 “Start Source” (Default) Input functions as defined by P036

[Start Source].

1 “Acc/Dec Sel1” If active, can determine which Accel/Decel time will be used

for all ramp rates except jog. Can be applied to one input

only. Refer to A067

[Accel Time 2] for details.

2 “Jog” • When input is present, drive accelerates according to the

value set in A079

[Jog Accel/Decel] and ramps to the

value set in A078

[Jog Frequency].

• When input is removed, drive ramps to a stop according to

the value set in A079

[Jog Accel/Decel].

• A valid “Start” command will override this input.

3 “Aux Fault” When enabled, an F2 Auxiliary Input

fault will occur when the

input is removed.

4 “Preset Freq” Refer to A070

- A077 [Preset Freq x].

Important: Digital Inputs have priority for frequency control

when programmed as Preset Speed and are active. Refer to

the flowchart on page 1-27

for more information on speed

reference control priority.

5 “Reserved”

6 “Comm Port” • When active, sets communications device as default start/

speed command source.

• Can only be tied to one input.

7 “Clear Fault” When active, clears an active fault.

8 “RampStop,CF” Causes drive to immediately ramp to a stop regardless of how

P037

[Stop Mode] is set.

9 “CoastStop,CF” Causes drive to immediately coast to a stop regardless of

how P037

[Stop Mode] is set.

10 “DCInjStop,CF” Causes drive to immediately begin a DC Injection stop

regardless of how P037

[Stop Mode] is set.

Loading...

Loading...