Rockwell Automation Publication 6000-UM002E-EN-P - April 2018 127

Preventative Maintenance and Component Replacement Chapter 5

Professional Maintenance Service

Rockwell Automation also offers professional maintenance service provided by

the Rockwell Automation field support engineer, contact your local Rockwell

Automation sales person for more information.

Miscellaneous Preventive Maintenance Work

• Communicate with the customer regarding problems found during the

preventive maintenance process.

• Raise the problems found during the maintenance process.

• Provide relevant solutions and record them in the final report.

• Provide advice on operation and maintenance of the drive to the

customer’s maintenance personnel.

• Provide information about requirements for safe operation of the drive

and safety instructions.

• Provide information about operating conditions (environment,

temperature, and so on) required for stable operation of the drive.

• Obtain spare parts information from the customer to determine whether

they have sufficient stock. Recommended the customer to purchase

additional spare parts if required.

For more information, contact PF6000TechnicalSupport@ra.rockwell.com.

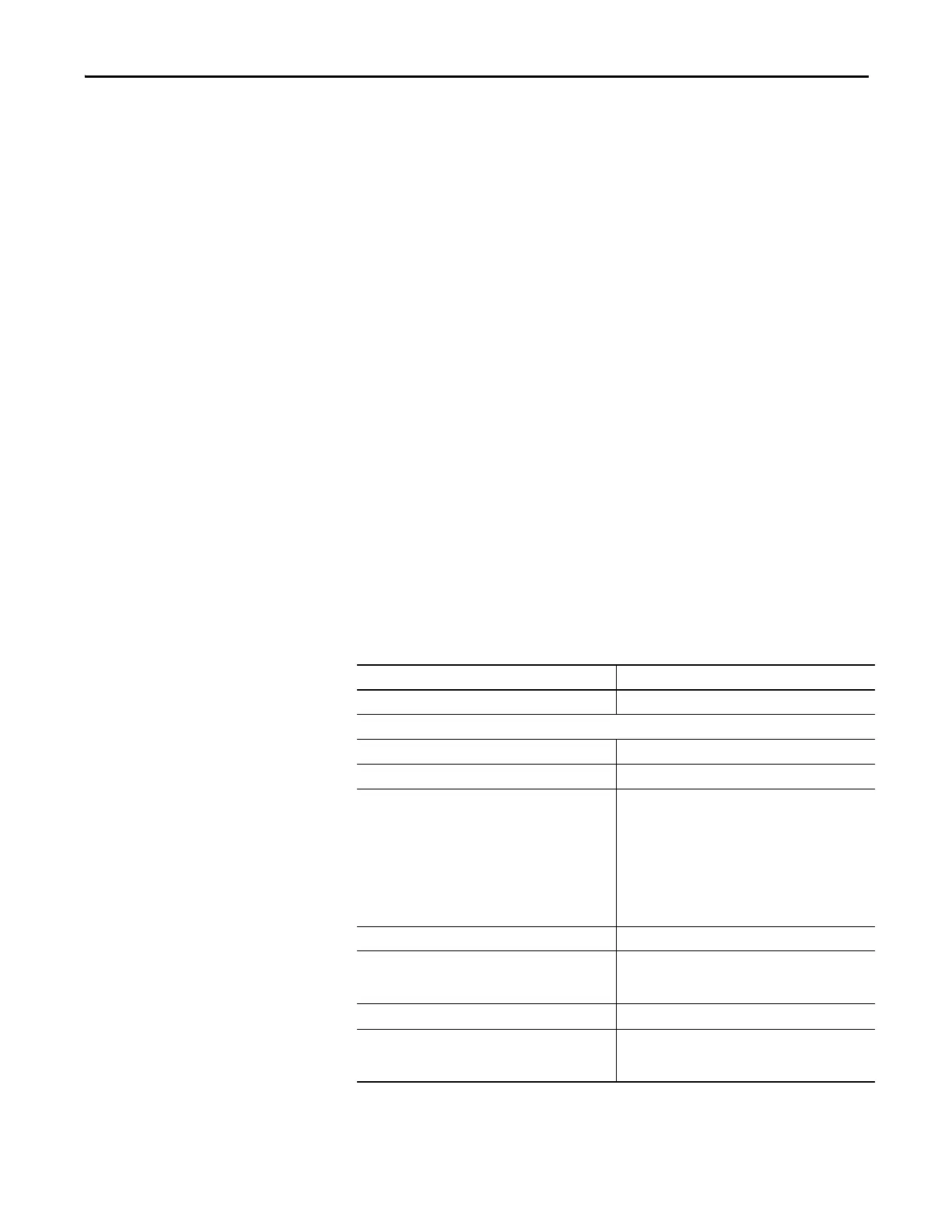

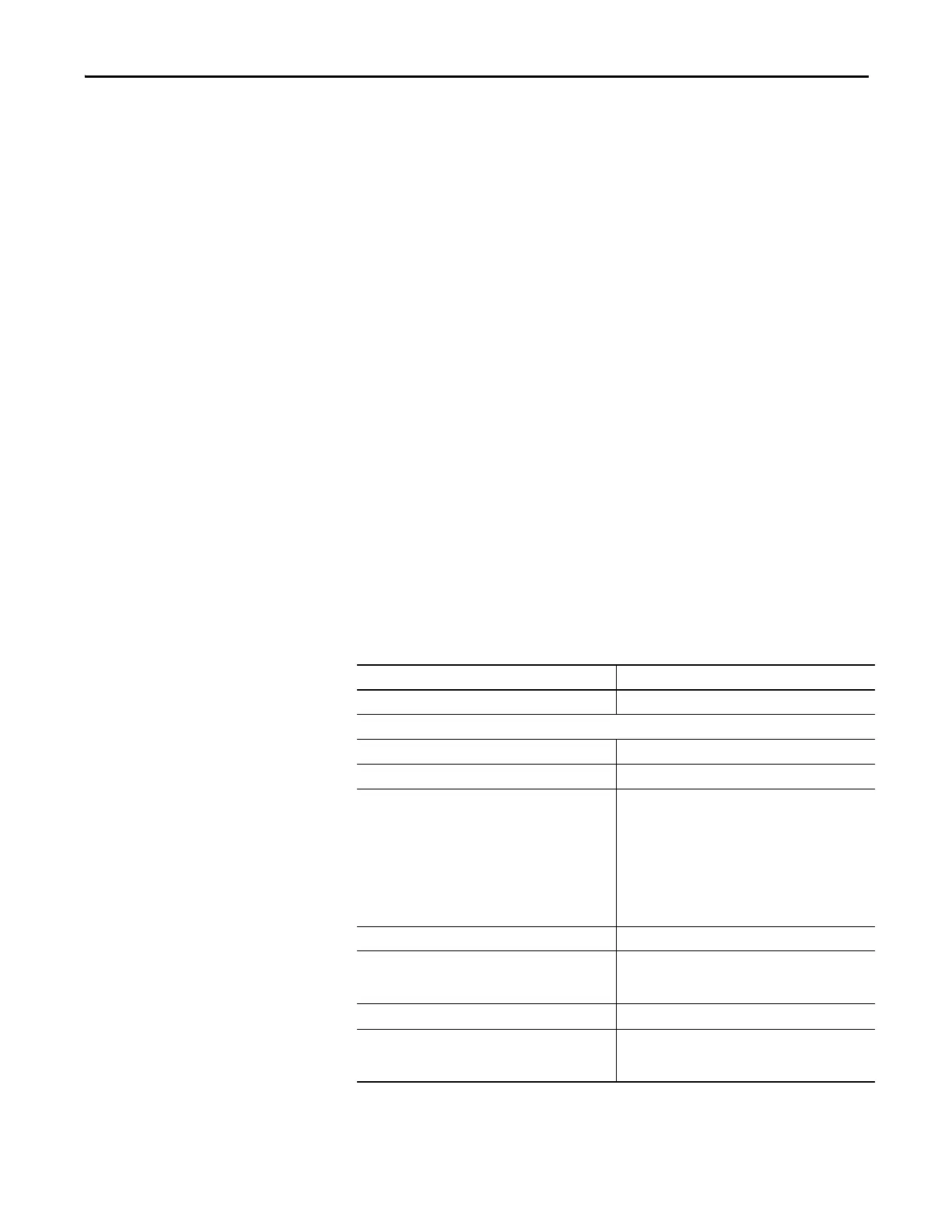

Table 9 - Estimated Time Required for Maintenance Work

Activity Time Required

Daily maintenance 0.5 hours for each air filter

Annual maintenance

Initial collection of information 0.5 hours

Visual inspection and cleaning 6.0 hours

• Electrical connection

• Ground

• Control cabinet

• Tra ns fo rmer cabinet

• Power cabinet

• Inside the Power Module

(1)

• Fan

• Door and mechanical parts

• Insulation

Low voltage check 2.0 hours

• Control system

• Cooling fan

• Parameters

Final inspection before commissioning 2.0 hours

• Final inspection

• Medium voltage test

(1)

• Run to maximum load Depending on the situation

Loading...

Loading...