60

use and maintenance RS 125

The adjusting nut must not be

screwed for more than 25 mm

from the beginning of the thread

(see figure). If this measure is

exceeded, even the slightest

unevenness on the road surface will

cause sudden jerks.

u

Act on the adjusting nut (1) (shock

absorber spring preload adjustment)

(see figure).

Turn the adjusting nut (1) one

turn at a time.

Test the vehicle repeatedly on

the road, until obtaining the optimal

adjustment.

CHECKING THE BRAKE PAD WEAR

Carefully read page 26 (BRAKE FLUID-

recommendations), page 26 (DISC

BRAKES) and page 43

(MAINTENANCE).

The following information refer to a

single braking system, but are valid for

both.

Check the brake pad wear after the first

1000 km (625 mi) and successively every

2000 km (1250 mi).

The wear of the brake pads depends on

the use, on the kind of drive and on the

road. The wear will be greater when the

vehicle is driven on dirty or wet roads.

Check the wear of the brake

pads, especially before every

trip.

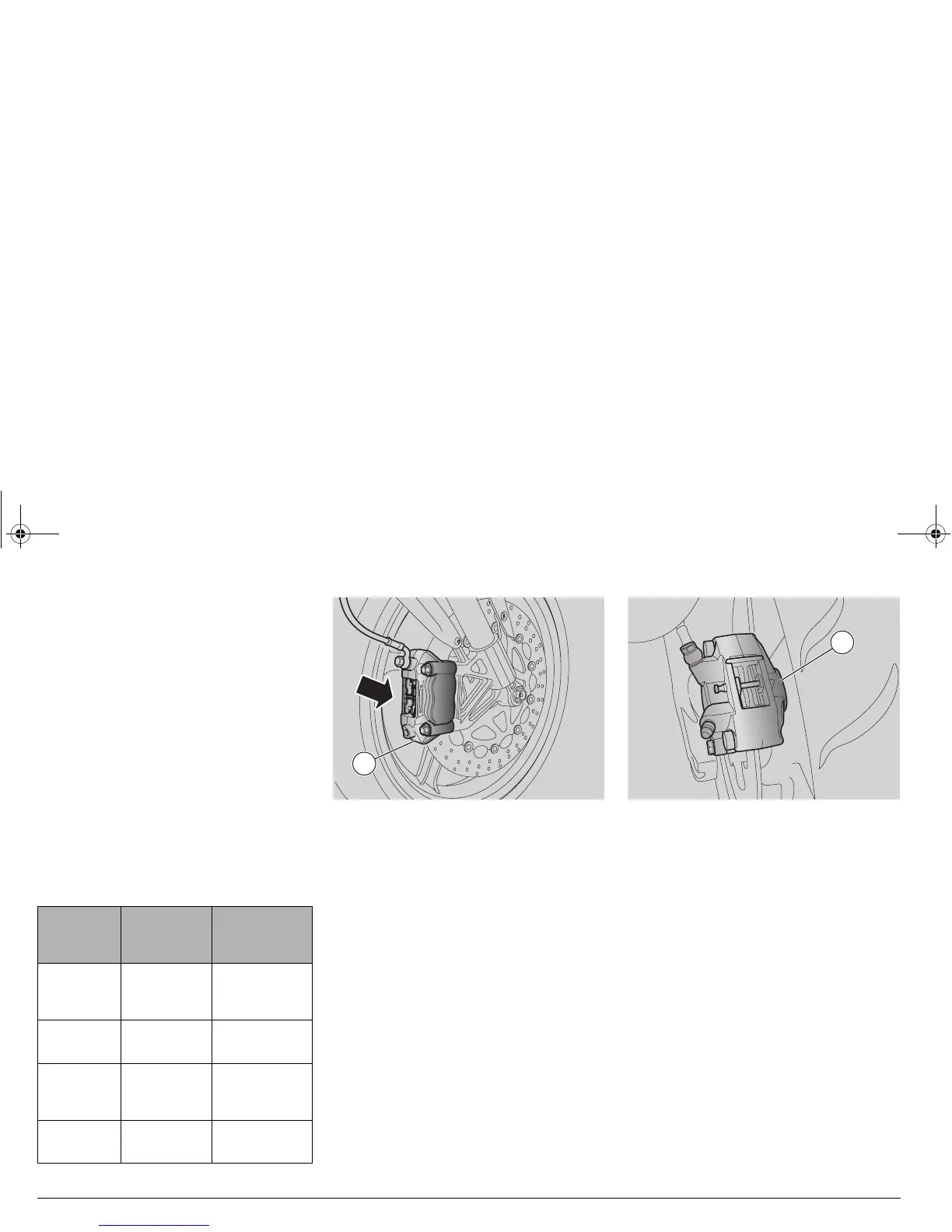

To carry out a rapid checking of the wear

of the pads, proceed as follows:

u

Position the vehicle on the stand.

u

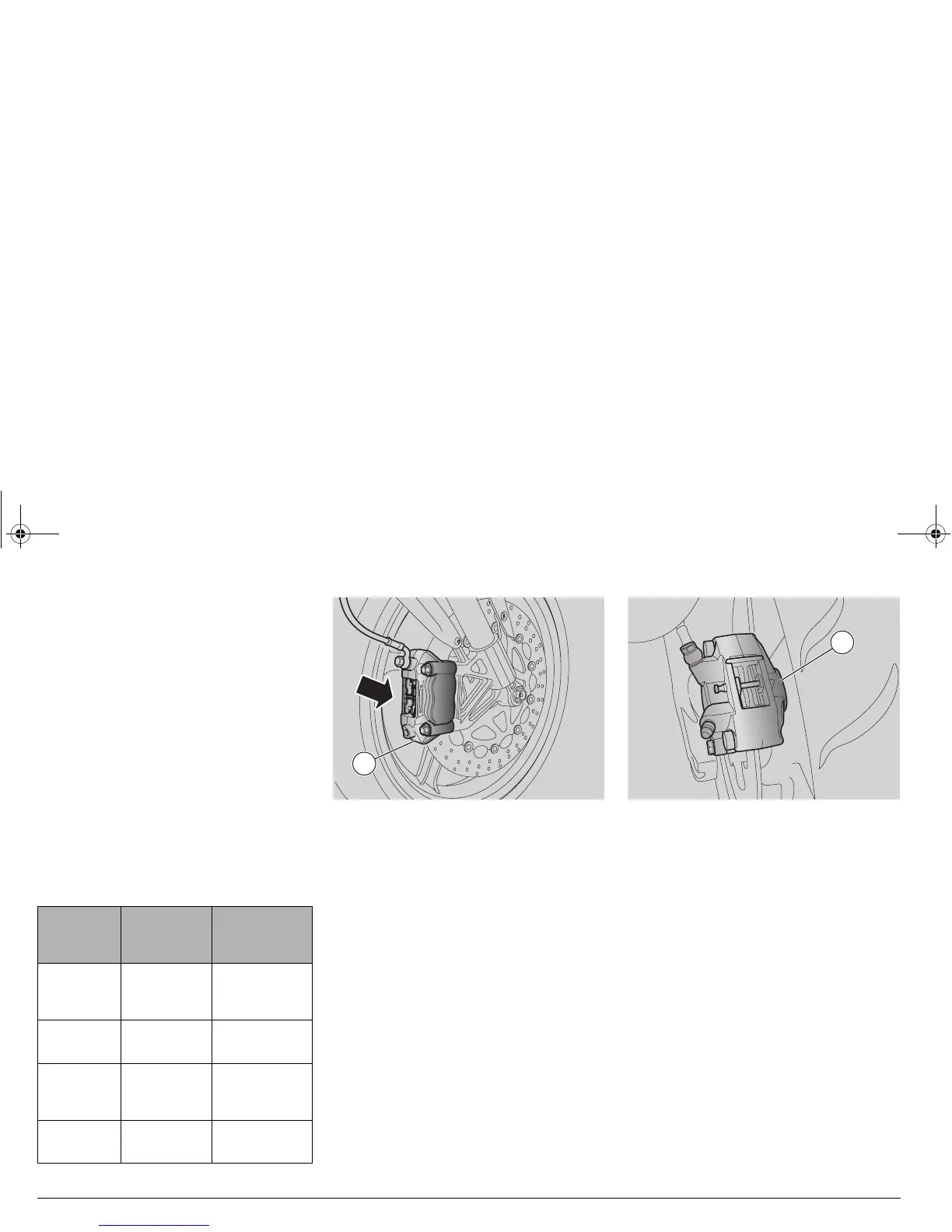

Carry out a visual checking of the friction

material thickness by looking between

the brake caliper and the pads.

Proceed:

– from below, on the front part, for the front

brake caliper (1);

– from below, on the rear part, for the rear

brake caliper (2).

Adjusting

nut (1)

By

screwing it

(clockwise)

By

unscrewing it

(anticlockwise)

Function Spring

preload

increase

Spring preload

decrease

Attitude The vehicle is

more rigid

The vehicle is

less rigid

Recommen

ded kind of

road

Smooth or

normal roads

Roads with

uneven

surface

Notes Rider and

passenger

Solo rider

1

2

RS_125_UK.book Page 60 Tuesday, June 13, 2006 1:34 PM

Loading...

Loading...