5-4. Disassembling the Valve Body

Precautions for disassembly

• Disassemble the valve body on a rag, etc., to avoid damaging the valve.

• After disassembling the valve body, protect the gasket-contacting surfaces, the valve plug-

contacting surfaces, sliding areas, seat ring, etc., with a rag or the like.

CAUTION

Dispose of old parts that were replaced during valve disassembly or main-

tenance as industrial waste. If they are burned or discarded carelessly, envi-

ronmental pollution will result.

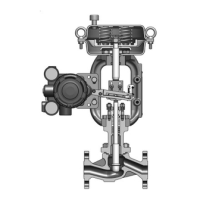

Disassembly procedure

Disassemble the control valve, referring to

Figure 5-2 to Figure 5-4 “Valve body structure.”

(1) Detaching the bonnet from the valve

Step Procedure

1 Loosen the nuts for the packing flange.

2 With the open-end wrench or box wrench, loosen the hex nuts that hold the bonnet to

the valve.

3 Check if the pressure in the valve has been released completely.

Remove the nuts.

4 Remove the bonnet from the valve. Be sure to hoist the bonnet slowly and vertically

by, for example, using a hoisting tool, so that the valve stem does not move to the side.

If the valve plug comes off along with the bonnet, tap the plug lightly with a plastic

hammer so that the seat of the valve plug and the seat ring is not damaged, and slide it

off from the bonnet by its own weight.

5 Remove the gasket between the valve and the bonnet.

WARNING

Before disassembling the valve body, check that the pressure

in the valve has dropped to atmospheric pressure. If fluid

spews out, injury may result.

Before disassembling the valve body, wash out the inside the

valve or replace the fluid. Otherwise, the residual fluid in the

pipe may cause an injury.

5-4

Loading...

Loading...