(3) Tightening

Step Procedure

1

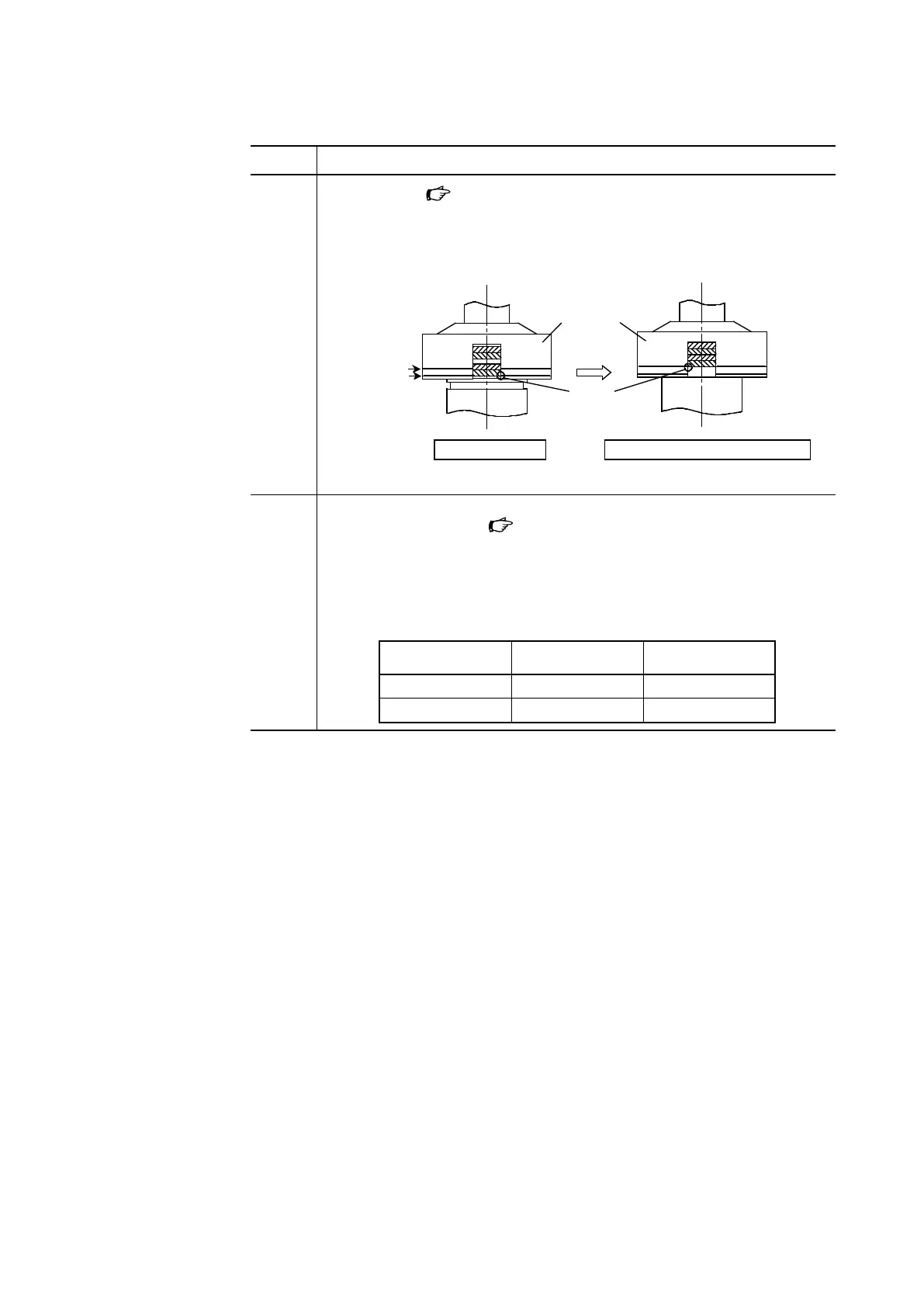

With reference to

Figure 8-5, check the position of the Belleville springs through

the front window of the spring case. When the Belleville springs are set properly, the

bottom of the lowest Belleville spring and the lower scale line on the spring case will

be at almost the same level. (The level may not be exactly the same due to the dimen-

sional tolerance of the Belleville springs)

Spring case

(front)

Bottom

of the lowest piece

Before tightening Tightened to the specied torque

Figure 8-5. Load on Belleville springs

2 Tighten the left and right gland nuts alternately, making approximately a half turn each,

until the torque indicated in

Table 8-4 is reached. Note that if the tightening torque

is insufficient, the amount of leakage may exceed the specified value. On the other

hand, tightening the gland nuts with excessive torque increases the friction on the

stem and causes the gland packing to wear out faster, which may lead to an amount of

leakage exceeding the specified value in a short period of time.

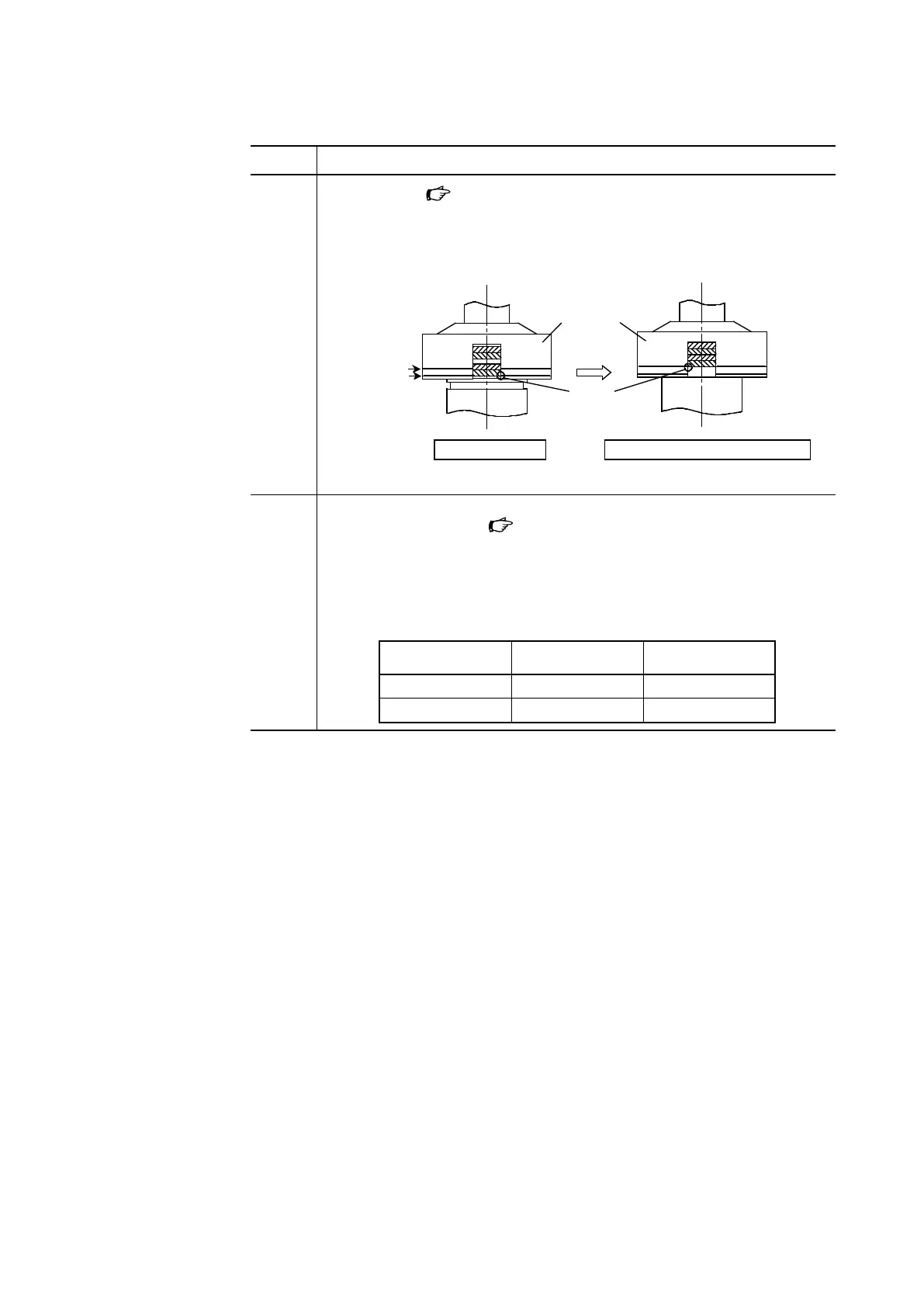

Table 8-4. Gland nut tightening torque

Actuator model Valve stem size Tightening torque

PSA1, PSA2

φ 13 mm

6 to 7 N·m

PSA3, PSA4

φ 16 mm

15 to 17 N·m

8-3-3. Retightening

In the following cases, retighten the gland nuts with the specified torque:

a) In the inspection before control valve installation

b) In a trial operation or start-up operation of the equipment

c) If the amount of leakage from the gland exceeds the specified value during operation of

the equipment

Note that, if the amount of leakage from the gland still exceeds the specified value after

retightening, reassemble all parts of the gland. In that case, replacement of the gland packing

and Belleville springs with new ones is recommended.

8-5

Loading...

Loading...