(2) New parts

When assembling or reassembling, for the parts indicated in the table below, be sure to use

new parts.

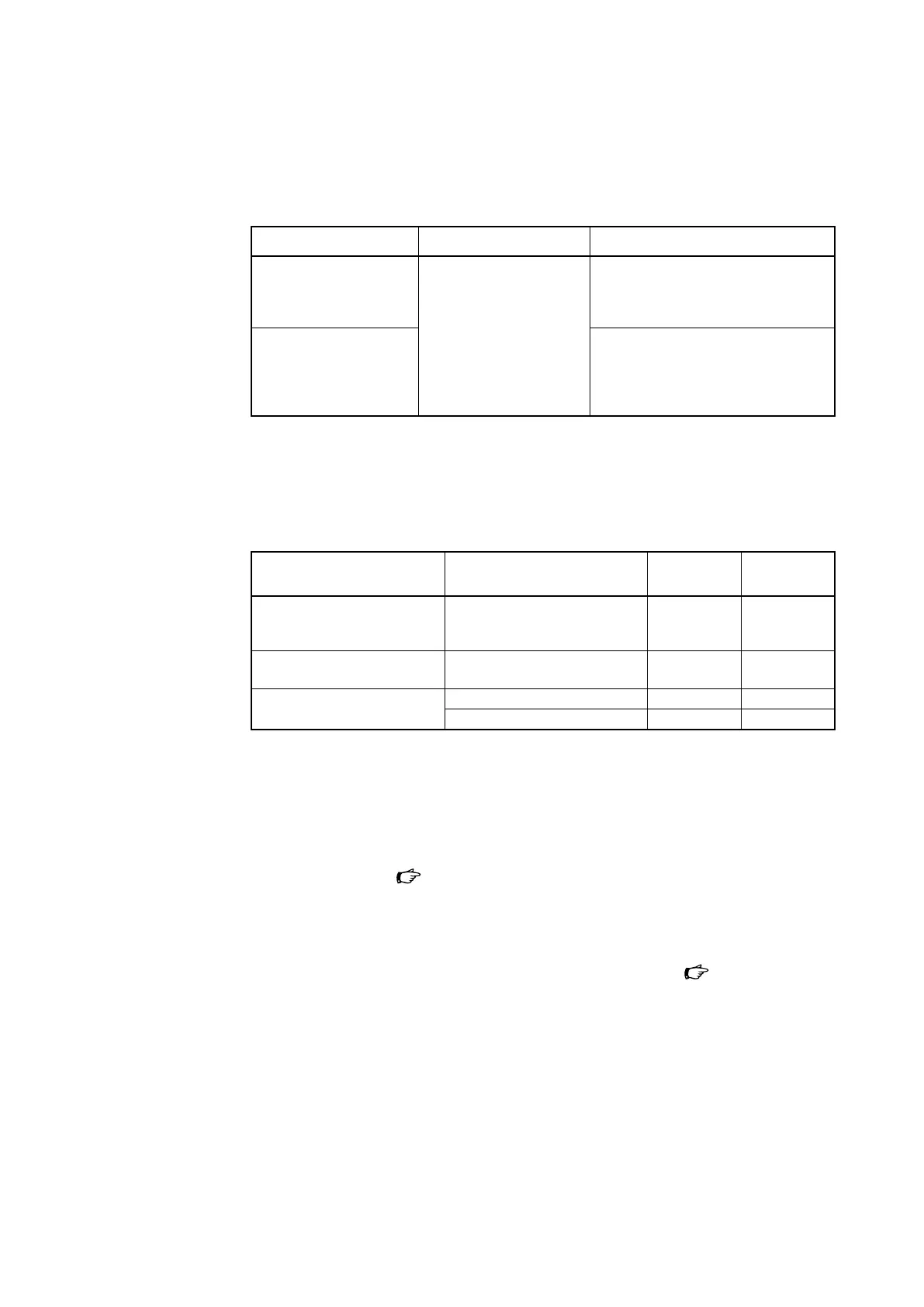

Table 9-2. Parts requiring replacement

Part name Checkpoints Possible problems

Gland packing (main pack-

ing and adapter packing)

Carbon ring

No flaws. No coating mate-

rials or dirt stuck to the

surface.

Any flaw, coating material, dirt, etc., may

cause leakage from that area, and the

specified seal performance may not be

achieved.

Belleville spring Any flaw, coating material, dirt, etc., may

cause insufficient tightening and leak-

age from the gland in a short period of

time, and the specified seal performance

may not be achieved.

(3) Lubricating grease and anti-seizing agent

Have an appropriate amount of the following lubricating grease and anti-seizing agent (or

equivalent) on hand.

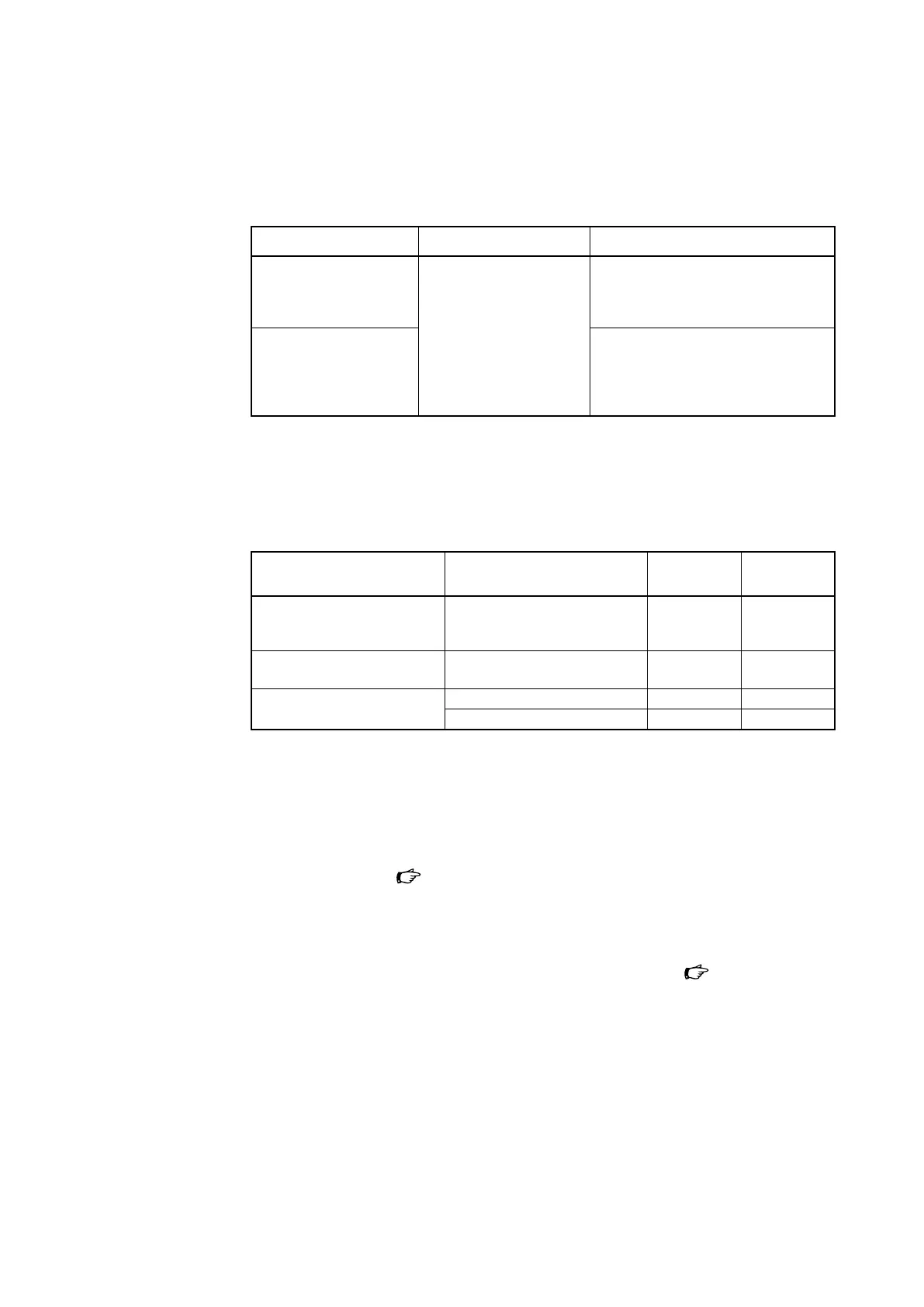

Table 9-3. Lubricating grease and anti-seizing agent

Product name Applied area PTFE yarn Expanded

graphite

Krytox GPL207 fluoropolymer

grease made by DuPont Co.

Entire surface of the gland pack-

ing (main packing and adapter

packing)

Needed –

Plastilube No. 3 non-dripping

grease, made by Sulflo Inc.

Entire surface of the O-rings Needed Needed

Never-Seez anti-seizing agent,

made by Bostik Inc.

Threads of the gland stud bolts Needed Needed

Bottom of the gland nuts Needed Needed

9-4-2. Assembly

(1) Applying lubricating grease

Step 1 For PTFE yarn gland packing, apply a thin film of Krytox GPL207 grease, as

indicated in

Table 9-3, to the entire surface of all gland packing (main packing

and adapter packing). For expanded graphite packing, greasing is not necessary.

Step 2 For the gland packing system with two O-rings, which are placed around the inner

and outer diameter of the packing follower, apply Plastilube No. 3 grease made by

the U.S. company Sulflo, Inc., to both rings, as indicated in

Table 9-3.

9-3

Loading...

Loading...