Chapter 8. Low-Emission Gland Packing System

8-1. Overview

Azbil’s low-emission gland packing system employs a live-loaded packing system to maintain

valve seal performance for a long period of time. In order to meet the emission regulations

for volatile organic compounds (VOC) required by U.S. Clean Air Act Amendments (CAAA),

we confirmed that the amount of leakage from the gland was the equivalent of not more than

500 ppm in terms of atmospheric concentration of methane based on Azbil Corporation’s own

evaluation criteria.*

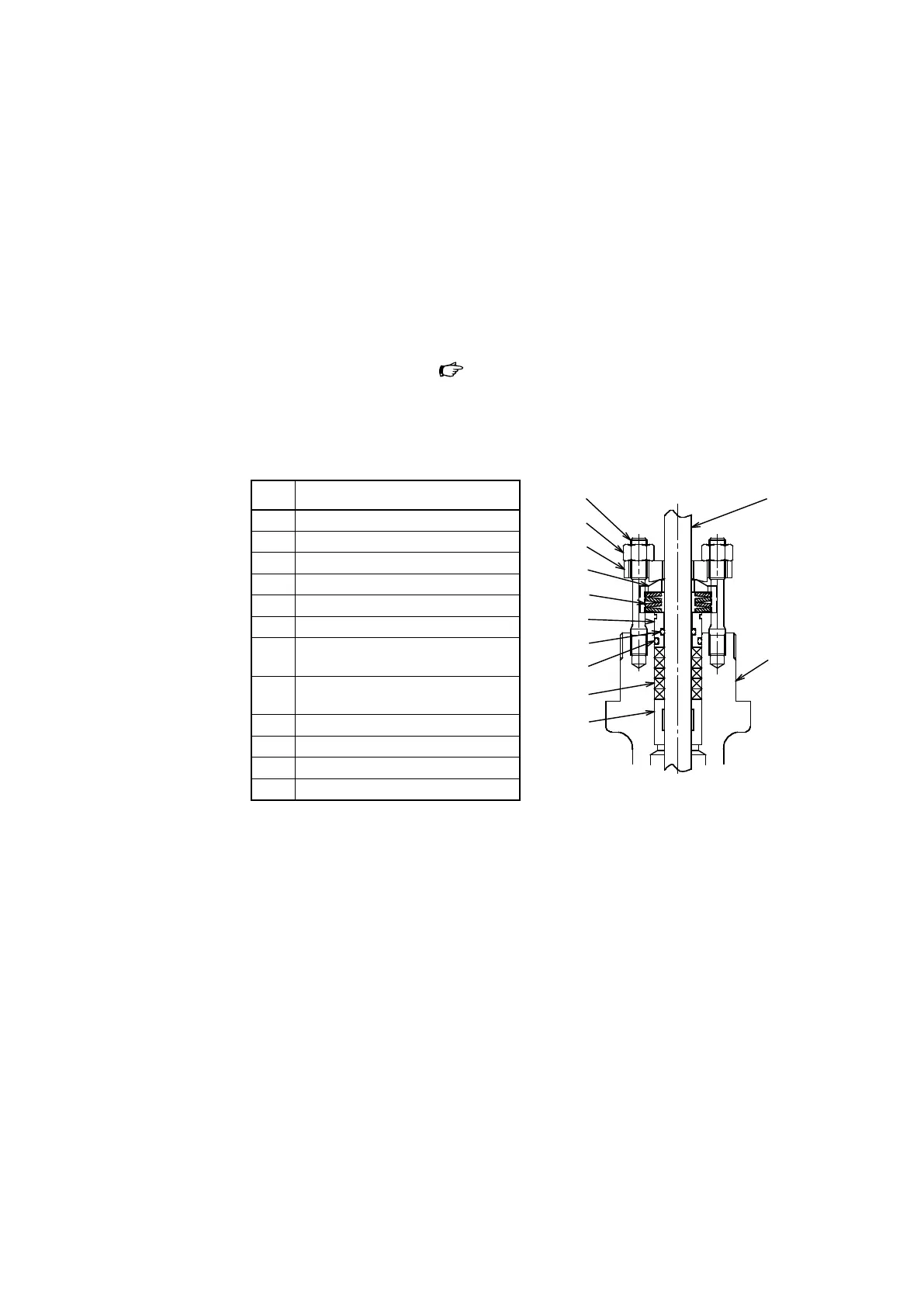

For the structure of the gland,

Figure 8-1. Structure of Azbil’s low-emission gland packing

system.

* As of October 2005, there were no industrial standards that specify the method of evaluation

for gland leakage, either in Japan or overseas.

No. Name

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(1) Gland stud bolt

(2) Gland nut

(3) Packing flange

(4) Spring case

(5) Belleville spring

(6) Packing follower

(7)

O-ring for inner side of packing

follower

(8)

O-ring for outer side of the packing

follower

(9) Gland packing

(10) Spacer

(11) Stem

(12) Stuffing box

Figure 8-1. Structure of Azbil’s low-emission gland packing system

8-2. Structure

The gland packing (P4519) is PTFE yarn with a carbon fiber core. It features asbestos-free

properties in addition to low sliding friction and adaptability to heat cycles, and can be used

for various types of fluids.

The gland packing is fastened by the live-loaded packing system composed of Belleville

springs. At the initial fastening, the Belleville springs should be fully compressed. With other

systems, in the course of valve operation, seal performance deteriorates due to loosening of

the gland packing. The restoring force of the Belleville springs automatically retightens the

packing to maintain the seal. The Belleville springs are installed in the spring case for the

purposes of positioning and protection from the surrounding environment. The load on the

Belleville springs can be observed by checking their position through the front window of the

spring case using the scale on the case.

The low-emission gland packing system can be added to an existing control valve, if it is an

applicable model, without replacing the valve body or actuator.

8-1

Loading...

Loading...