© BEKA 201 !6 All rights reserved

BAL2185_PICO_with_PICOtroniX1_PICOtronic_0816_EN

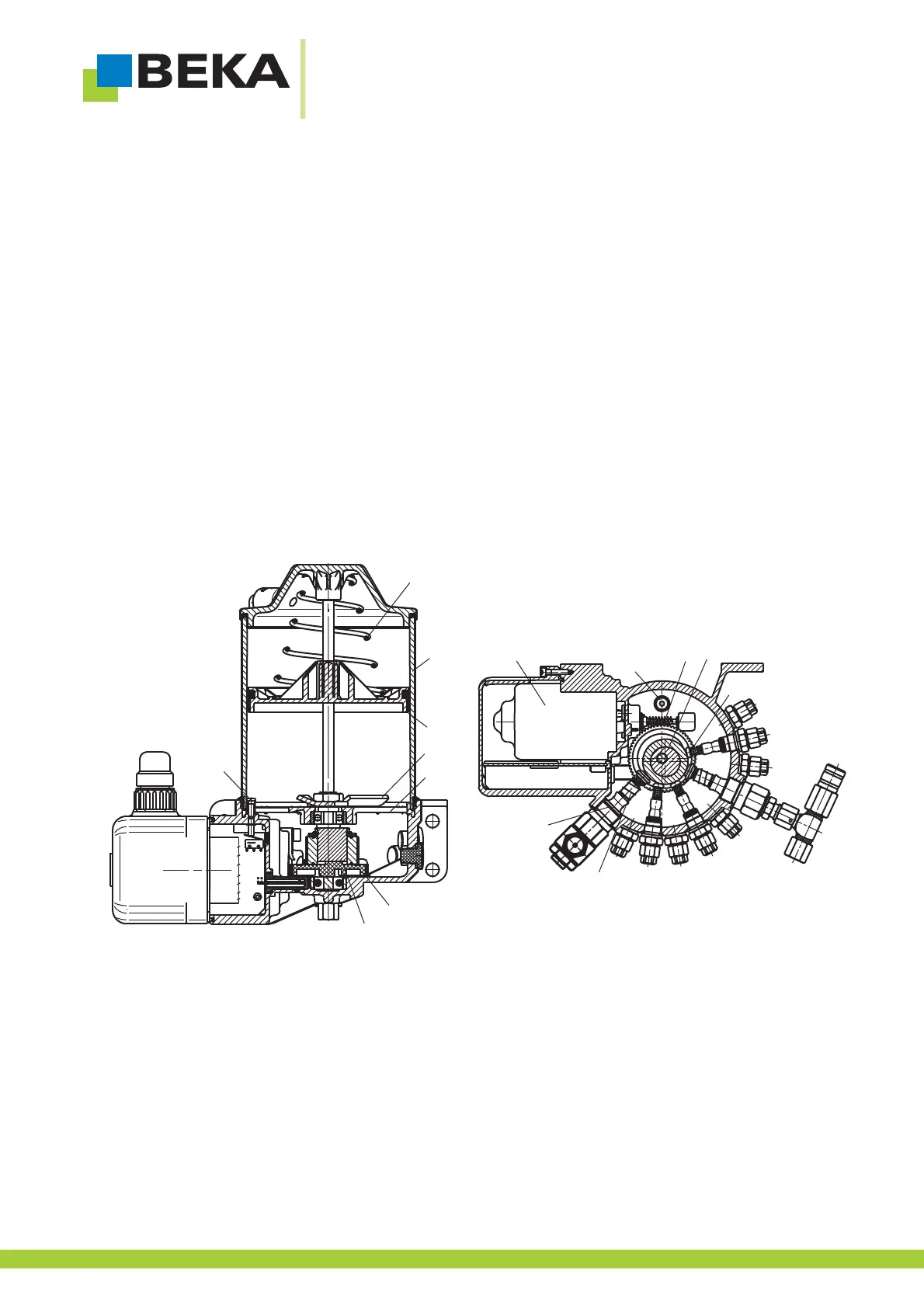

7.3 Functional description of the central lubrication pump PICO

The DC motor (pos. 1, fig. 3) (12 or 24 V DC) actuates the eccentric shaft (pos. 3, fig. 3) via a worm gear (pos. 2, fig. 3).

Due to the rotational movement and the eccentricity, the pistons (pos. 4, fig. 3) of the pump elements are pressed into the

piston outlet fitting (pos. 5, fig. 3) (= delivery stroke). The piston springs help to press back the pistons (pos. 6, fig. 3) into

theinitial position(=suction stroke).

The non-return valve avoids that the displaced output rate is primed back again. There is an agitator blade (pos. 8, fig. 3)

abovethe greasesieve (pos. 7,fig. 3) thatis fixconnected with theeccentric shaft.

The agitator blade (pos. 8, fig. 3) presses the lubricant into direction of the pump element. There is a follower piston (pos.

10,fig. 3)in the reservoir(pos. 9, fig.3) thatispressed tothe bottom bythe conicalcoilspring (pos.11, fig.3).

The piston has the task to press lubricant consistently to the agitator blade or the pump elements. Due to the use of the

followerpistons, thehorizontal pump assemblyis notmandatory.

If the reservoir is empty, the follower piston (pos. 10, fig. 3) on a tracer pin (pos. 12, fig. 3). This one sends a signal to the

contorlunit (reservoirempty).

The filling is realized via the conical lubrication nipple at the pump housing. There is a overfill protection (pos. 13, fig. 3)

thatavoids anoverfill of thepump.

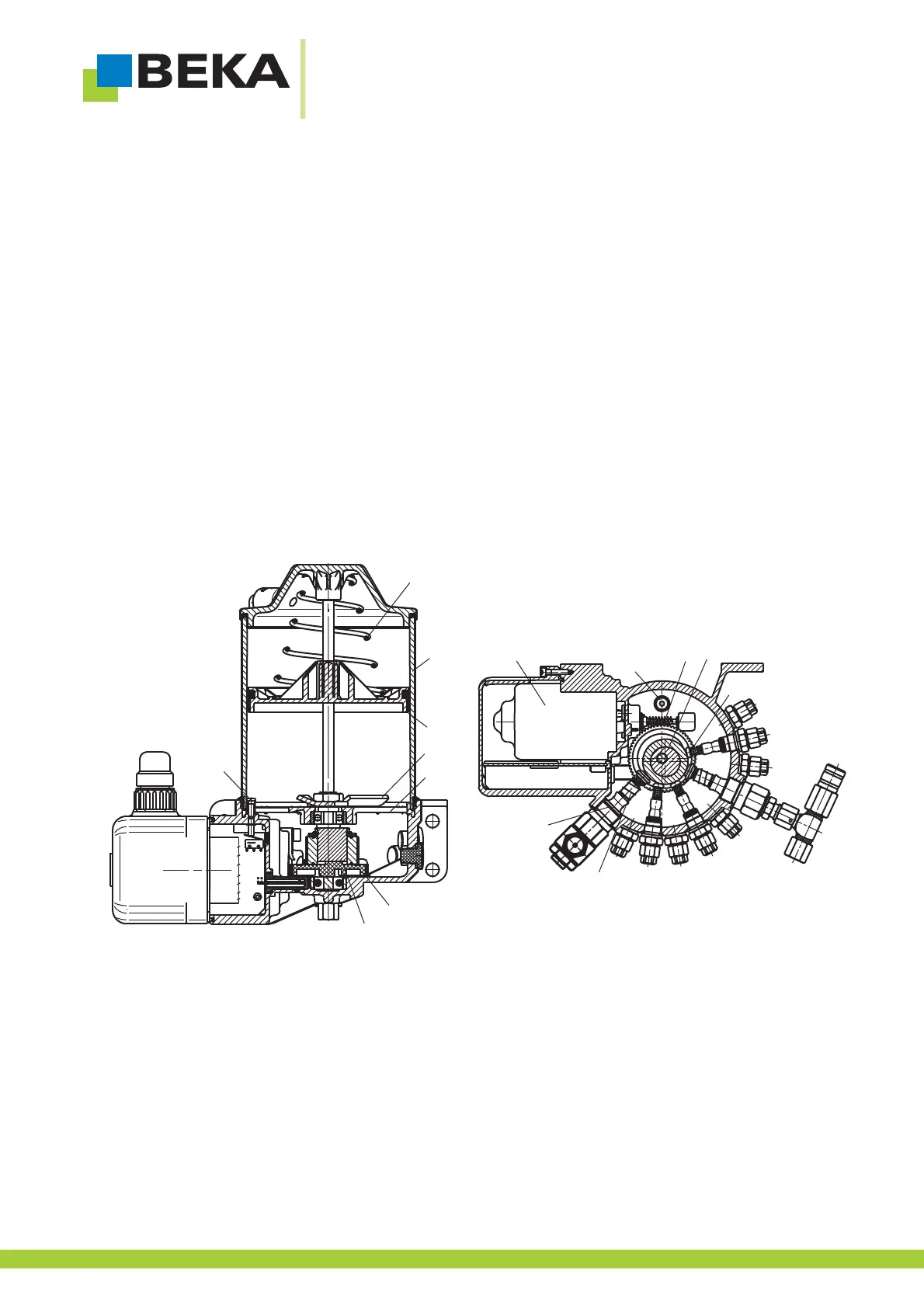

Fig.3:

3

9

8

10

7

11

2

12

1

13

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

Loading...

Loading...