© BEKA 201 !6 All rights reserved

BAL2185_PICO_with_PICOtroniX1_PICOtronic_0816_EN

...a product of BEKA

9.6 Additional function of line rupture monitoring at distributor

The integrated control unit PICO-tronic can electronically

evaluate the line rupture monitoring at the progressive

distributor.

Micro switches are installed at the progressive distributor

MX-F. They send signals to the control unit as long as there

isenough pressurein the line.

If the line pressure drops, e.g. because the machine with

installed lubrication system has been switched off during the

night,the microswitches stop sendingthe signal.

If the machine and lubrication system is switched on again, the pump start to build up the pressure in the line. If this is not

possible after the set number of start cycles (standard 2) and following set monitoring time (standard 1 min.), because for

example, a line is ruptured or leaky, the control unit sends a malfunction signal (see 12.3 signals of the integrated control

unitPICO-tronic).The pumpcontinues operating tolubricate the lubepoints thatareconnected atthe faultless lines.

The micro switches are connected in row. If a micro switch does not activate the signal, the signal for the control unit is

missing.If thepressure is buildup again afterthe repair, theerror isautomaticallyreset.

Theconnection atthe control unitis done viathe leftHirschman plug atthe control unithousing ofthepump (seefig. 28).

Ifthe additionalfunction „line rupturemonitoring“ is used,the followingfunctions are notavailable:

· Operating mode cyclecontrol pulse-dependent

· Monitoring of pressurein linesystem (system pressuremonitoring)

9.7 Special function of external status signal

ThePICO-tronic canevaluate a aserror signal oras .status signal (standard) OK signal

Thesetting issend asa ,as soonas an erroris available.error signal permanent signal

IThesetting interruptsthe permanentsignal as soonas there isan error.OK signal

Theevaluation canbe done viaa relay ora lamp.

Signals:

· No pulse cyclewas receivedwhile the monitoringtime

· The distributor receivedno pulseduring the monitoringtime.

· The pump motorsensor receivedno speed pulseduring the monitoringtime.

· Reservoir is empty.

· System pressure toohigh (system).

· Operating pressure inthe lineis not reached(line rupture monitoring).

· The lubrication duringcycle durationcan not befinished (lubrication deficit).

· Error „memory /CPU“ isavailable.

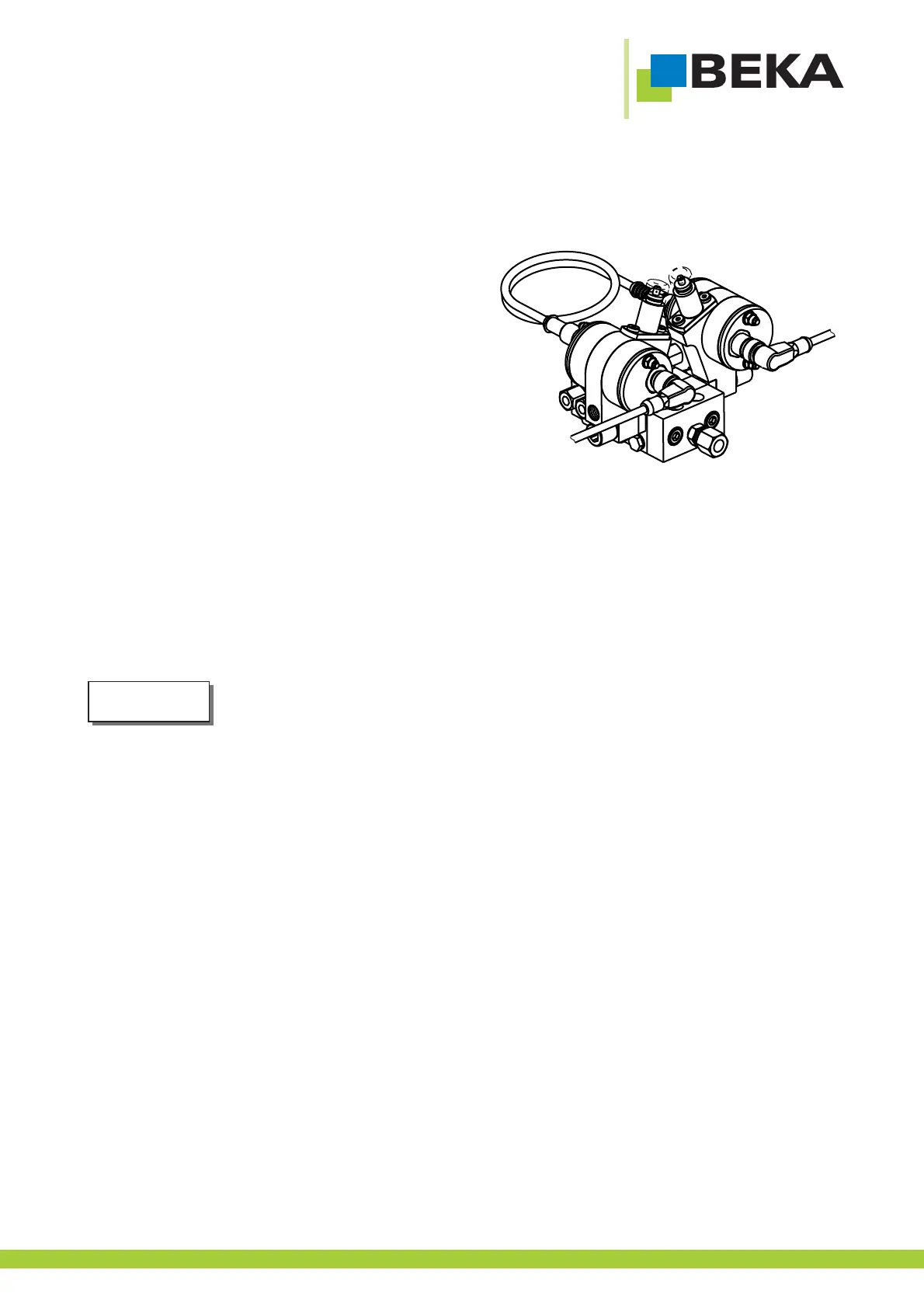

Fig. 38:

Note!

Loading...

Loading...