10. STANDARD ADJUSTMENTS

BAS-326G PS

56

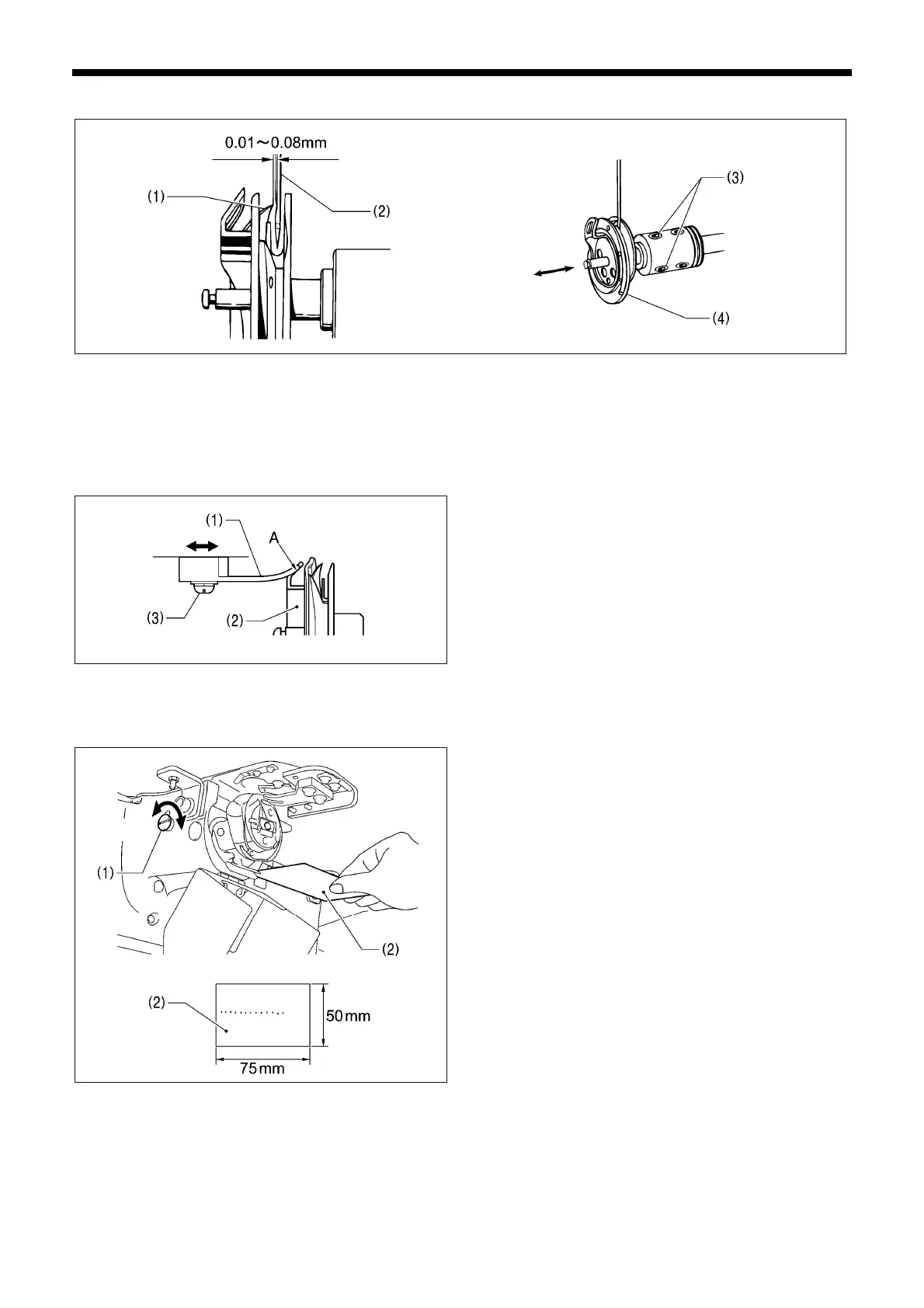

10-7. Adjusting the needle clearance

Turn the machine pulley to align the rotary hook tip (1) with the center of the needle (2), and then loosen the two set screws

(3) and move the rotary hook (4) forward or back to adjust so that the clearance between the needle (2) and the rotary hook

tip (1) is 0.01 − 0.08 mm.

10-8. Adjusting the inner rotary hook and hook stopper overlap

Loosen the two screws (3) to adjust so that the tip of the

hook stopper (1) does not protrude past edge A of the inner

rotary hook (2).

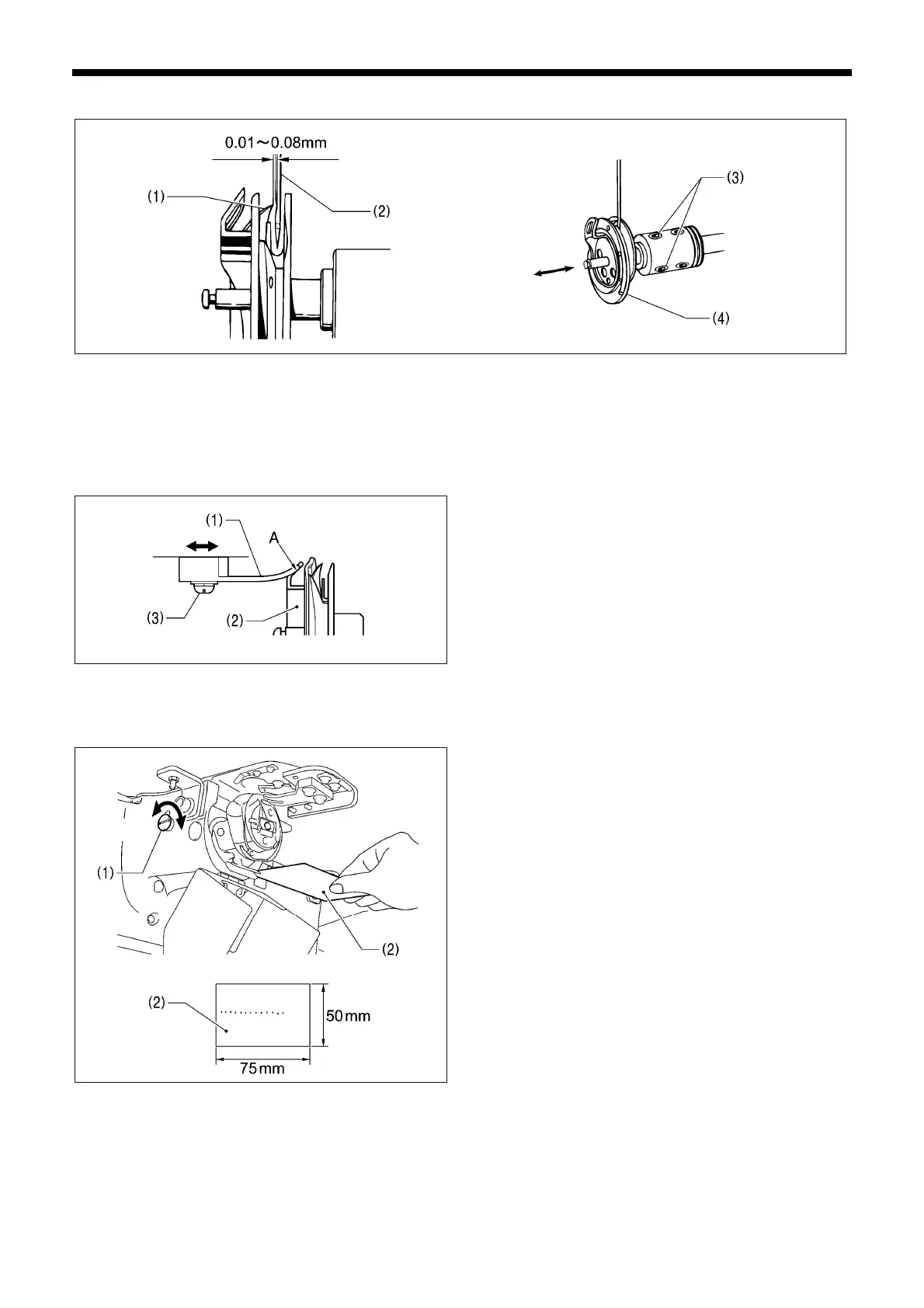

10-9. Rotary hook lubrication amount

Turn the adjusting screw (1) to adjust the lubrication

amount.

* Adjust so that approximately 10 drops of oil are released

when the sewing machine is run at a speed of 2,700

sti/min for three cycles to sew about 150 stitches. Use

Kraft paper (2) or similar to catch the oil drops. As a

guide, the optimum position can be obtained if the

adjusting screw (1) is tightened as much as possible and

then loosened about one turn.

• If the adjusting screw (1) is turned clockwise, the

lubrication amount becomes smaller.

• If the adjusting screw (1) is turned counterclockwise,

the lubrication amount becomes greater.

1883B

1884B

1908B

1885B

More oil

Less oil

Loading...

Loading...