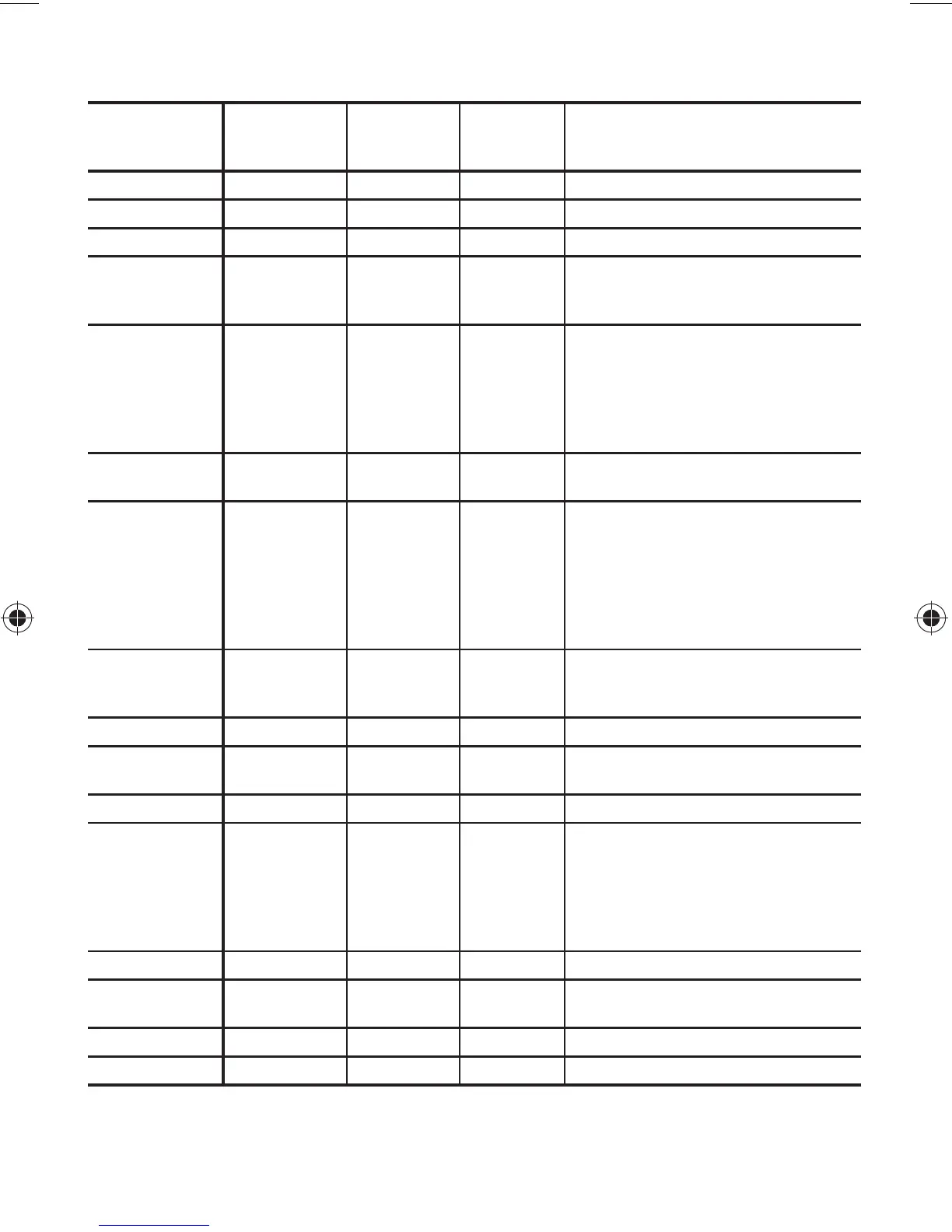

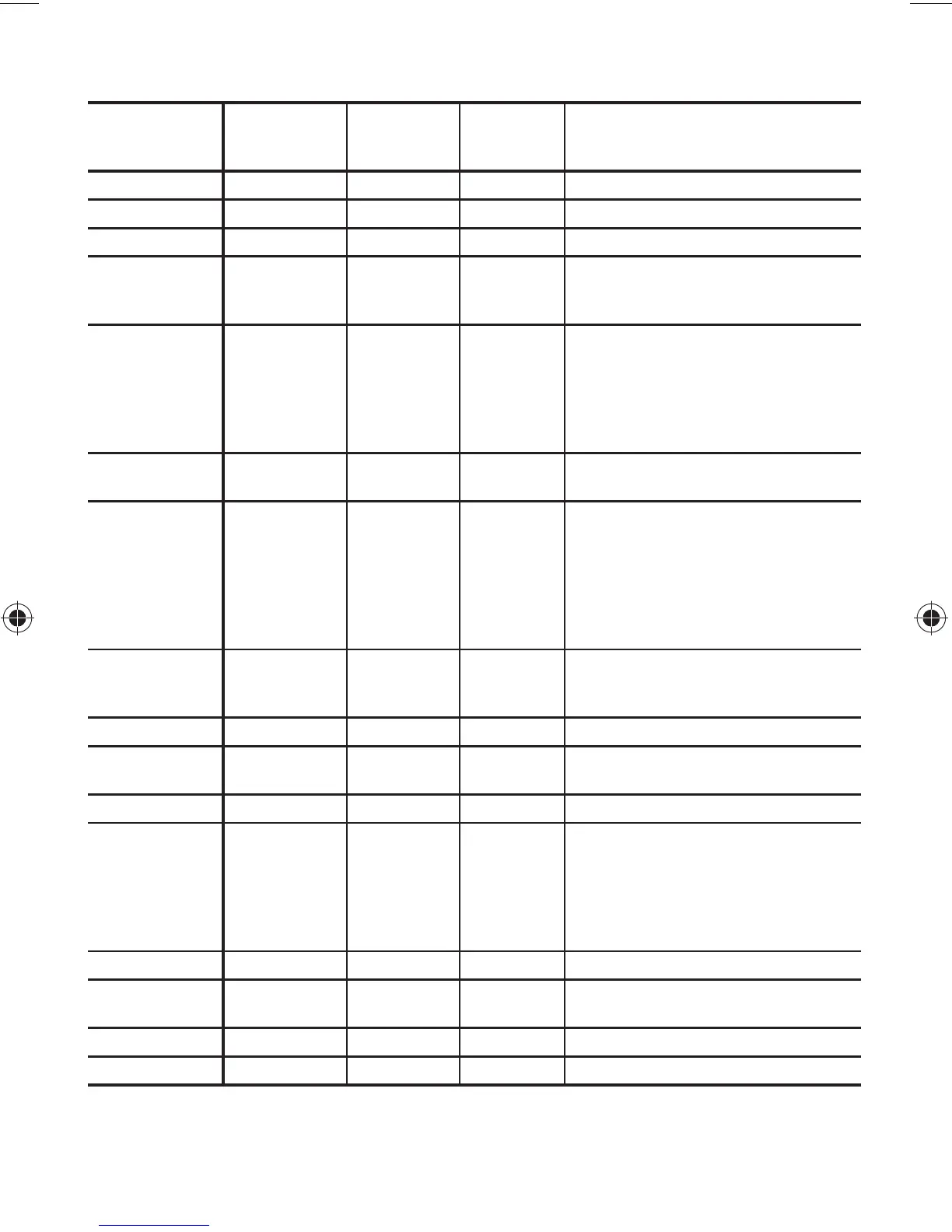

61

2.11 — Torque Guide - 06E and 06CC (50 to 99 Cfm)

Compressors

See Table 2.10 for Notes and Legend (page 60).

SIZE

DIAMETER

(in.)

THREADS

PER INCH

TORQUE

RANGE

(FT-LB)

TORQUE

RANGE

(NM)

USAGE

1/16 Pipe 8-12 11-16 Pipe plug crankshaft

1/8 Pipe 10-12 14-16 Orifice crankcase

No. 10 324-65-8 Oil pump drive segment

1/4 20

10-12

1.5-2.5

14-16

2-3

Con-rod cap screw

Motor lead set screw terminal

plate

1/4 28

3-5

4-6

12-15

12-15

12-15

12-15

4-7

5-8

16-20

16-20

16-20

16-20

Sight glass

Cylinder head gasket tab screw

Terminal box

Unloader valve

Discharge valve stop

Oil pump drive segment

5/16 18

16-20

20-25

22-27

27-34

Cover plate bearing head

Discharge service valve (4-cyl)

3/8 16

12

1

12

10-20

30-35

30-35

30-35

16

1

16

14-17

40-48

40-48

40-48

Terminal post jam nut #1*

Terminal post jam nut #2*

Terminal post jam nut #3*

Oil plug bearing head

Bottom plate, crankcase

Compressor foot

Terminal block

3/8 24-S

AE 8-12 11-16

P.E. Bearing head at 10 o’clock

position

NOTE: Not a field usable fitting

5/8 18-SAE 25-40 27-54 Access port under motor barrel

7/16 14

55-60

55-60

75-81

75-81

Motor end cover, crankcase

Bearing head, crankcase

7/16 20-SAE 8-12 11-16 Oil drain on bottom plate

1/2 13

80-90

80-90

80-90

85-100

85-100

85-100

109-122

109-122

109-122

115-136

115-136

115-136

Discharge service valve (6-cyl)

Interstate outlet (CC)

Suction service valve (1-5/8)

Interstage manifold (CC)

Suction manifold (CC)

Cylinder head

1/2 Pipe 30-40 40-54 Cylinder head sensor

5/8 11

25-3 0

90-100

34-40

122-136

Rotor lock crankshaft

Suction service valve (2-1/8)

3/4 16 50-60 68-81 Stator lock acorn nut

1-1/8 1830-40 40-54 Pressure relief valve

Loading...

Loading...