38

NOTE: Before this operation we recommend draining the circuit

and disconnecting the pipes to be sure that the bolts are correctly

and uniformly tightened.

9.5.1 - Standard machine

If the chiller or the water piping is in an area where the ambient

temperature can fall below 0°C it is recommended to add an

antifreeze solution to protect the unit and the water piping to a

temperature of 10 K below the lowest temperature likely to be

reached at the installation site. Use only antifreeze solutions,

approved for heat exchanger duty. If the system is not protected

by an antifreeze solution and will not be used during the freezing

weather conditions, draining of the cooler and outdoor piping is

mandatory. Damage due to freezing is not covered by the warranty.

IMPORTANT: Depending on the climatic conditions in your area

you must:

•

Add ethylene glycol with an adequate concentration to protect

the installation up to a temperature of 10 K below the lowest

temperature likely to occur at the installation site.

• If the unit is not used for an extended period, it is

recommended to drain it, and as a safety precaution add

ethylene glycol to the heat exchanger, using the water

entering purge valve connection (a purge connection is

available somewhere on the heat exchanger water box in

case the machine is not perfectly level).

At the start of the next season, rell the unit with water

and add an inhibitor.

• For the installation of auxiliary equipment, the installer

must comply with basic regulations, especially for minimum

and maximum ow rates, which must be between the values

listed in the operating limit table (application data).

9.5.2 - Brine machine

30HXC brine applications below 0°C leaving brine temperature

are not compatible with stopped situations where water ow is

maintained in the evaporator and stopped in the condenser.

The water ow in the evaporator should preferably be stopped

after unit shut down. If this is not possible, then the ow must be

maintained in the condenser too.

In all cases, it is recommended to maintain the water ow in the

condenser few moments after the evaporator ow stopped to allow

safe pressure equilibrium.

Special attention has to be given to the hydraulic design when

option 152 is selected, in order to maintain the condenser ow

even when the 0-10V signal asks for no-ow.

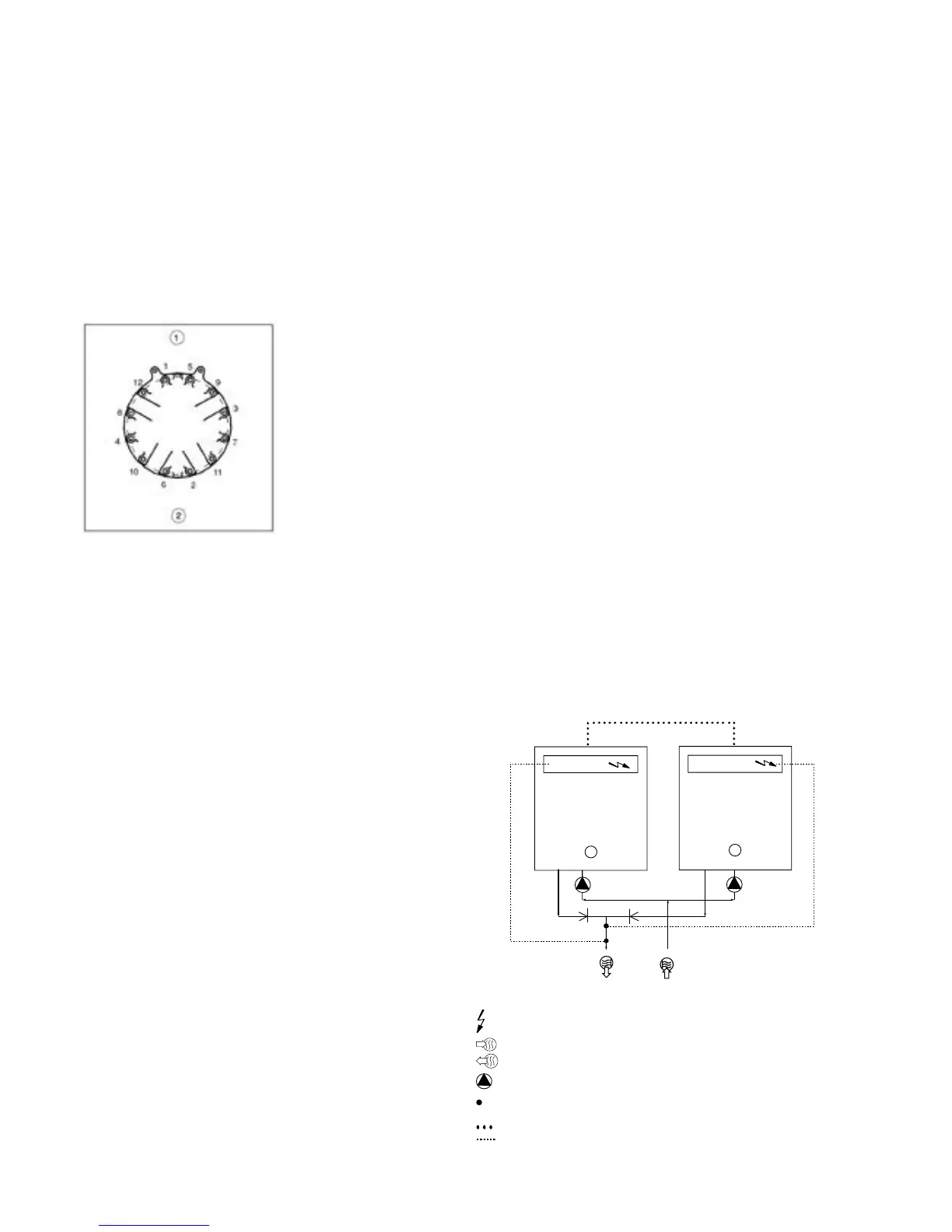

The control of a master/slave assembly is in the entering water

and does not require any additional sensors (standard conguration).

It can also be located in the leaving water. In this case two

additional sensors must be added on the common piping.

All parameters, required for the master/slave function must be

congured using the Service Conguration menu. All remote

controls of the master/slave assembly (start/stop, setpoint, load

shedding etc.) are controlled by the unit congured as master and

must only be applied to the master unit.

Each unit controls its own water pump. If there is only one

common pump, in cases with variable ow, isolation valves must

be installed on each unit. They will be activated at the opening

and closing by the control of each heat pump (in this case the

valves are controlled using the dedicated water pump outputs). See

the 30GX/HXC Pro-Dialog Plus Control IOM for a more detailed

explanation.

9.3.2 - Condenser water ow switch (30HXC)

The use of a condenser water ow switch is recommended. The

ow switch is not supplied, and must be installed on site and

connected in accordance with the wiring diagrams.

The condenser water ow rate must be set to 10 l/s.

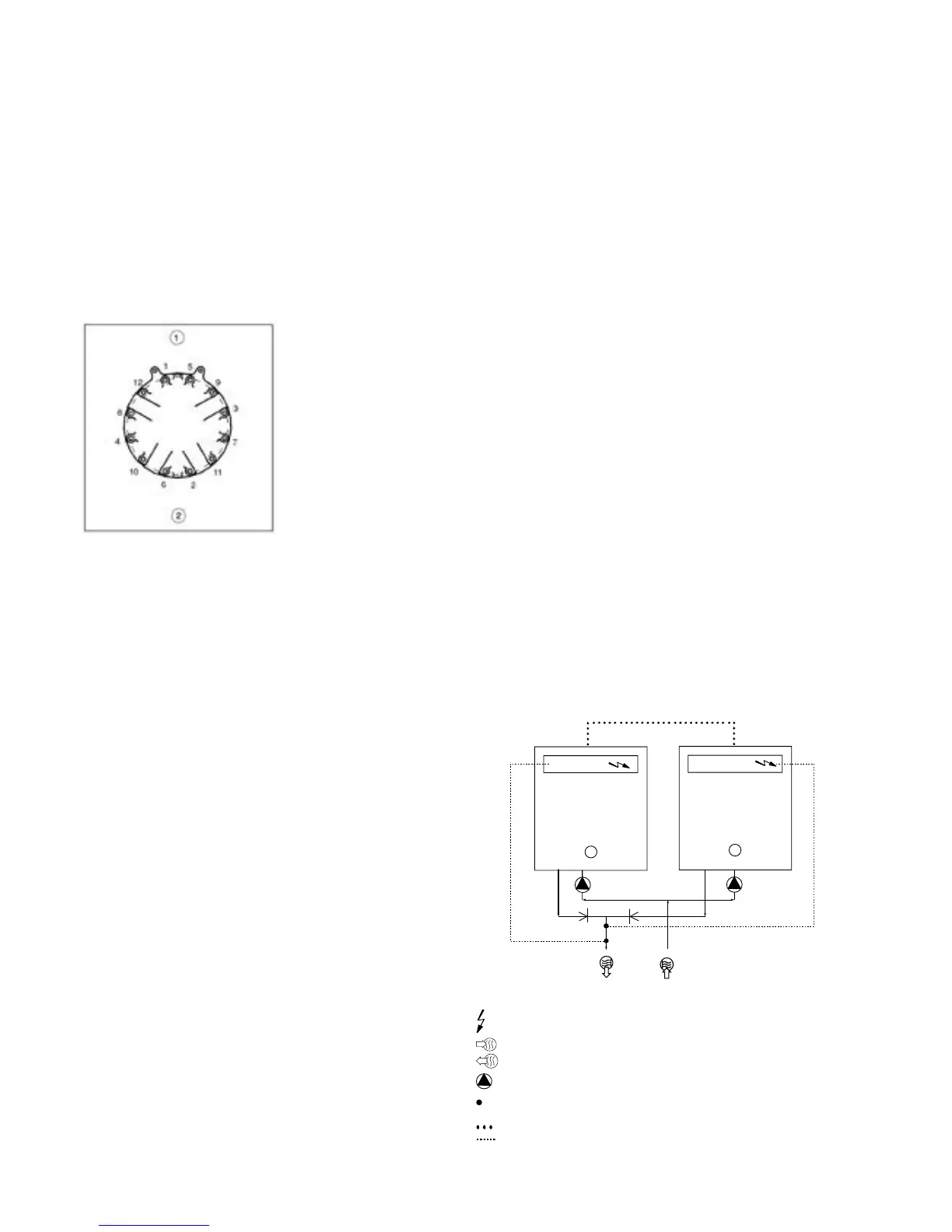

The evaporator (and condenser) are of the shell and tube type

with removable water boxes to facilitate cleaning. Re-tightening

or tightening must be done in accordance with the illustration

below.

1 Sequence 1: 1 2 3 4

Sequence2:5678

Sequence3:9101112

2 Tightening torque

BoltsizeM16-171-210Nm

Loading...

Loading...