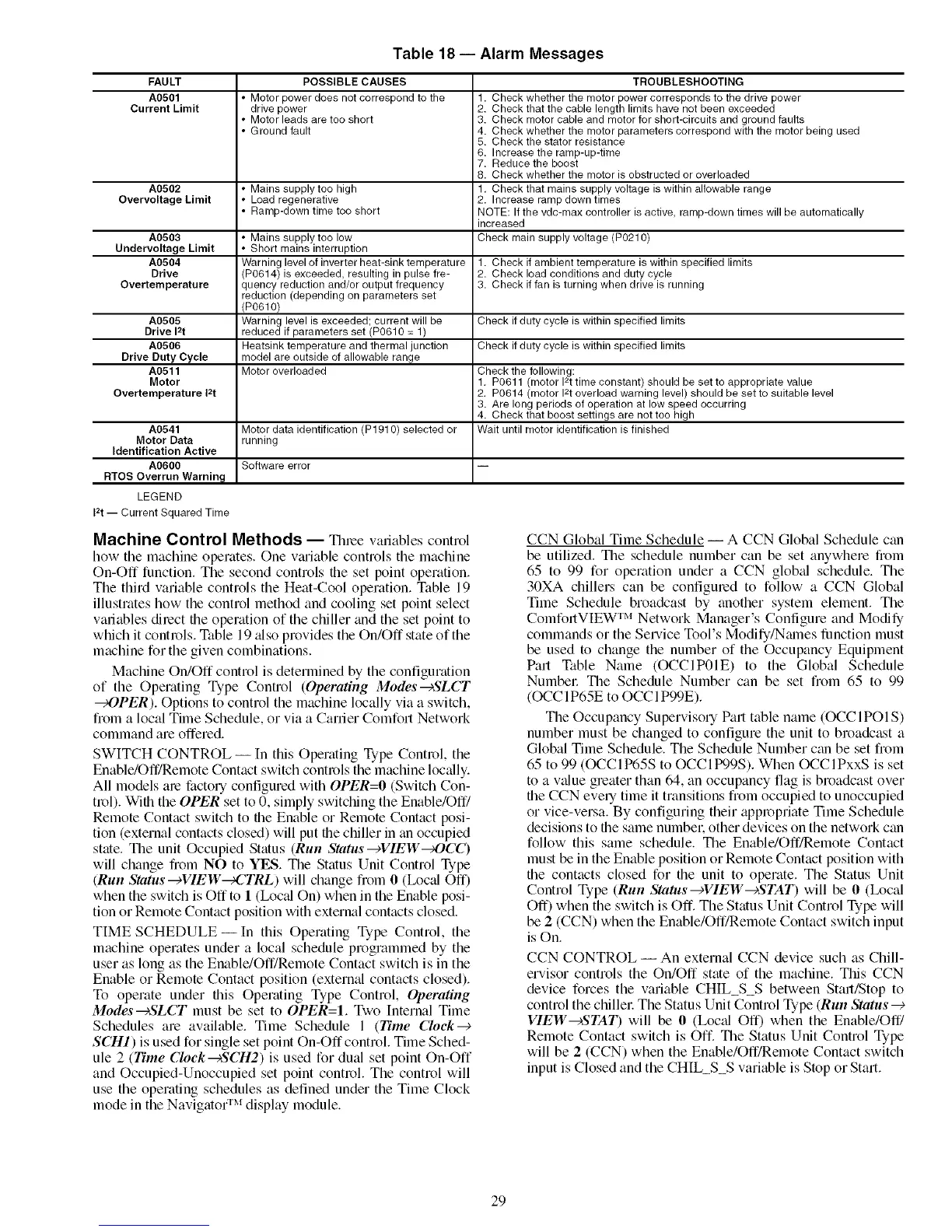

Table 18- Alarm Messages

FAULT

A0501

Current Limit

A0502

Overvoltage Limit

POSSIBLE CAUSES

• Motor power does not correspond to the

drive power

• Motor leads are too short

• Ground fault

• Mains supply too high

• Load regenerative

• Ramp-down time tee short

A0503 • Mains supply too low

Undervoltage Limit • Short mains interruption

A0504 Warning level of inverter heat-sink temperature 1. Check if ambient temperature is within specified limits

Drive (P0614) is exceeded, resulting in pulse fre- 2. Check load conditions and duty cycle

Overtemperature quency reduction and/or output frequency 3. Check iffan is turning when drive is running

reduction (depending on parameters set

(P0610)

A0505 Warning level is exceeded; current will be Check if duty cycle is within specified limits

Drive 12t reduced if parameters set (P0610 = 1)

A0506 Heatsink temperature and thermal junction Check if duty cycle is within specified limits

Drive Duty Cycle model are outside of allowable range

A0511 Motor overloaded Check the following:

Motor 1. P0611 (motor 12ttime constant) should be set to appropriate value

Overtemperature 12t 2. P0614 (motor 12toverload warning level) should be set to suitable level

3. Are long periods of operation at low speed occurring

4. Check that boost settings are not too high

A0541 Motor data identification (P1910) selected or Wait until motor identification is finished

Motor Data running

Identification Active

A0600 Software error

RTOS Overrun Warnin_

LEGEND

i2t -- Current Squared Time

TROUBLESHOOTING

1. Check whether the motor power corresponds to the drive power

2. Check that the cable length limits have not been exceeded

3. Check motor cable and motor for short-circuits and ground faults

4. Check whether the motor parameters correspond with the motor being used

5. Check the stator resistance

6. Increase the ramp-up-time

7. Reduce the boost

8. Check whether the motor is obstructed or overloaded

1. Check that mains supply voltage is within allowable range

2. Increase ramp down times

NOTE: If the vdc-max controller is active, ramp-down times will be automatically

increased

Check main supply voltage (P0210)

Machine Control Methods -- Tinge variables control

how the machine operates. One vmiable controls the machine

On-Off function. The second controls the set point operation.

The third variable controls the Heat-Cool operation. Table 19

illustrates how the control method and cooling set point select

variables dilect file operation of the chiller and the set point to

which it controls. Table 19 _flso provides the On/Off state of the

machine for the given combinations.

Machine On/Off control is determined by the configuration

of the Operating Type Control (Operating Modes--+SLCT

_OPER). Options to control the machine locally via a switch,

from a local Time Schedule, or via a Carrier Comfort Network

command are offered.

SWITCH CONTROL --In this Operating Type Control, the

Enable/Off/Remote Contact switch controls the machine locally.

All models are factory configured with OPER=O (Switch Con-

trol). With the OPER set to 0, simply switching the Enable/Off/

Remote Contact switch to file Enable or Remote Contact posi-

tion (external contacts closed) will put the chiller in tin occupied

state. The unit Occupied Status (Run Status-+VIEW_OCC)

will change fiom NO to YES. The Status Unit Control Type

(Run Status--_VIEW_CTRL) will change fiom 0 (Ix_cal Off)

when the switch is Off to 1 (Ix_cal On) when in the Enable posi-

tion or Remote Contact position with external contacts closed.

TIME SCHEDULE- In this Operating Type Control, the

machine operates under a local schedule programmed by the

user as long as the Enable/Off/Remote Contact switch is in the

Enable or Remote Contact position (external contacts closed).

To operate under this Operating Type Control, Operating

Modes-+SLCT must be set to OPER=I. Two Internal Time

Schedules are available. Time Schedule 1 (Time Clock--_

SCH1) is used for single set point On-Off control. Time Sched-

ule 2 (Time Clock_SCH2) is used for dual set point On-Off

and Occupied-Unoccupied set point control. The control will

use the operating schedules as defined under the Time Clock

mode in the Navigato( r_'_display module.

CCN Global Time Schedule -- A CCN Global Schedule can

be utilized. The schedule number can be set anywhere from

65 to 99 for operation under a CCN glob_d schedule. The

30XA chillers can be configmed to follow a CCN Global

Time Schedule broadcast by another system element. The

IM

ComfortVIEW Network Manager's Configure and Modily

commands or the Selwice Tool's Modify/Nmnes function must

be used to change the number of the Occupancy Equipment

Part Table Name (OCCIP01E) to the Global Schedule

Numbel: The Schedule Number can be set from 65 to 99

(OCC 1P65E to OCC 1P99E).

The Occupancy Supervisory Part table name (OCCIPOI S)

number must be changed to configure the unit to broadcast a

Global Time Schedule. The Schedule Number can be set from

65 to 99 (OCCIP65S to OCCItX)9S). When OCCIPxxS is set

to a v_due greater than 64, an occupancy flag is broadcast over

the CCN every time it transitions from occupied to unoccupied

or vice-versa. By configuring their appropriate Time Schedule

decisions to fl-_esame numbel, other devices on the network can

follow this same schedule. The Enable/Off/Remote Contact

must be in the Enable position or Remote Contact position with

flae contacts closed for the unit to operate. The Status Unit

Control Type (Run Status--cVIEW--cSTAT) will be 0 (Ix_cal

Off) when the switch is Off. The Status Unit Control Type will

be 2 (CCN) when the Enable/Off/Remote Contact switch input

is On.

CCN CONTROL -- An external CCN device such as Chill-

ervisor controls the On/Off state of the machine. This CCN

device forces the variable CHIL_S_S between Start/Stop to

control the chillel: The Status Unit Control Type (Run Status--€

VIEWS'TAT) will be 0 (Loc_d Off) when the Enable/Off/

Remote Contact switch is Off. The Status Unit Control Type

will be 2 (CCN) when the Enable/Off/Remote Contact switch

input is Closed and the CHIL_S_S variable is Stop or Start.

29