START-UP

Do not manu_dly operate contactors. Serious damage to the

machine may result.

Actual Start-Up- Actual start-_q) should be done only

under Sul)eia'ision o/ a quali/ied r@'igerution Wchniciun.

1. Be sure all oil, discharge, suction service valves (if

equipped) and liquid line service valves are open.

2. Using the Navigato( r_'rdisplay, set leaving-fluid set point

(Set PoOlt_COOL_4JSP.I). No cooling range adjust-

ment is necess_uy.

3. If optional control functions or accessories _ue being

used, the unit must be properly configured. Refer to

Configuration Options section for details.

4. Complete the Start-Up Checklist to verily all components

ale operating properly.

5. Turn Enable/Off/Remote contact switch to Enable position.

6. Allow unit to operate and confirm that everything is

functioning properly. Check to see that leaving fluid

temperature aglees with leaving set point Control Point

(Run Status ---)VIEW_4JTPT).

Operating Limitations

TEMPERATURES- Unit operating temperature limits are

listed in Table 27.

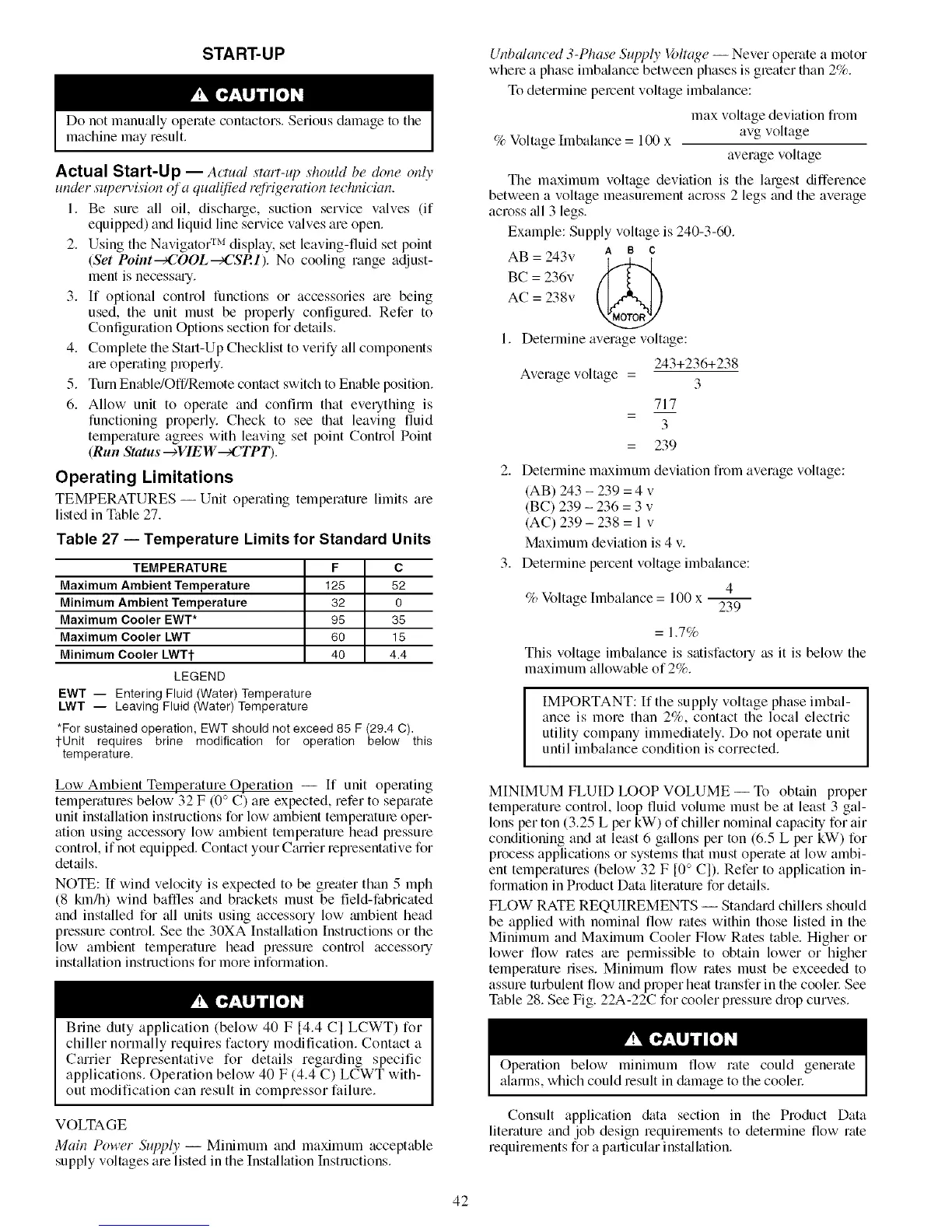

Table 27 -- Temperature Limits for Standard Units

TEMPERATURE 1F5 CMaximum Ambient Temperature 52

Minimum Ambient Temperature 32 0

Maximum Cooler EWT* _095 35

Maximum Cooler LWT 60 15

Minimum Cooler LWTt 4.4

LEGEND

EWT -- Entering Fluid (Water) Temperature

LWT -- Leaving Fluid (Water) Temperature

*For sustained operation, EWT should not exceed 85 F (29.4 C).

1-Unit requires brine modification for operation below this

temperature.

Low Ambient Temperature Operation -- If unit operating

temperatures below 32 F (0 ° C) are expected, refer to separate

unit installation instructions for low ambient temperature oper-

ation using accessory low ambient temperature head pressure

control, if not equipped. Contact your C_urier representative for

details.

NOTE: If wind velocity is expected to be greater than 5 mph

(8 kin/h) wind baffles and brackets must be field-fabricated

and installed for all units using accessory low ambient head

pressure control. See the 30XA Installation Instructions or the

low ambient temperature head pressure control accessory

installation instructions for more information.

Brine duty application (below 40 F [4.4 C] LCWT) for

chiller normally requires factory modification. Contact a

Canier Representative for details regarding specific

applications. Operation below 40 F (4.4 C) LCWT with-

out modification can result in compressor failure.

VOLTAGE

Muin Power Supply -- Minimum and maximum acceptable

supply voltages are listed in the Inst_dlation Instructions.

Unbalanced 3-Phase Supply Voltuge -- Never operate a motor

where a phase imb_dance between phases is greater than 2%.

To determine percent voltage imb_dance:

max voltage deviation from

avg voltage

% Voltage Imbalance = 100 x

average voltage

The maximum voltage deviation is the largest difference

between a voltage measurement across 2 legs and the average

across _dl 3 legs.

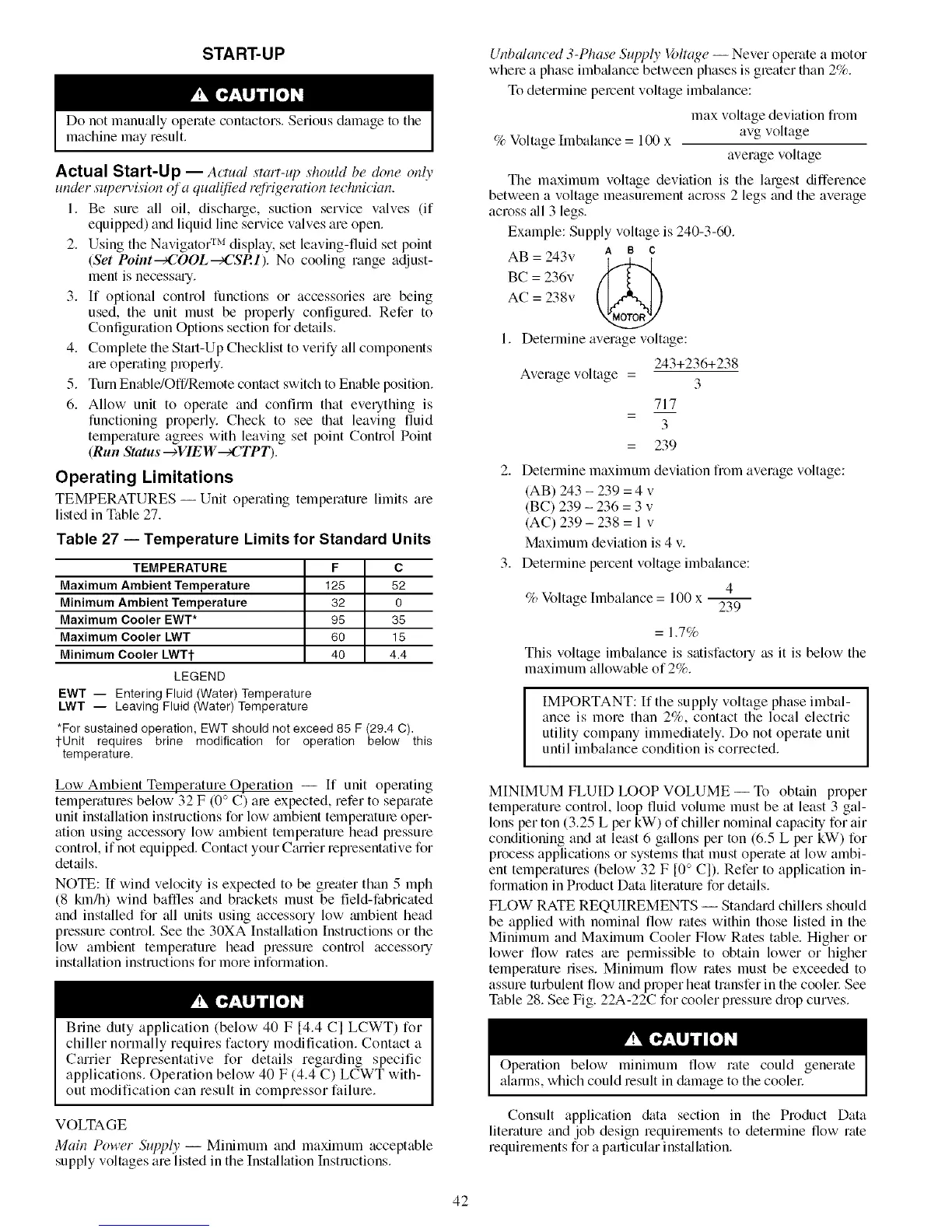

Example: Supply voltage is 240-3-60.

AB = 243v A B C

BC = 236v K I "_

AC = 238v

1. Determine average voltage:

Average voltage =

m

z

243+236+238

3

717

3

239

2. Determine maximum deviation from average voltage:

(AB) 243 - 239 = 4 v

(BC) 239 - 236 = 3 v

(AC) 239 - 238 = 1 v

Maximum deviation is 4 v.

3. Determine percent voltage imbalance:

4

% Voltage hnbalance = 100 x 23----7

= 1.7%

This voltage imbalance is satisfactory as it is below the

maximum allowable of 2%.

IMPORTANT: If the supply voltage phase imbal-

ance is more than 2%, contact the local electric

utility company immediately. Do not operate unit

until imbalance condition is corrected.

MINIMUM FLUID LOOP VOLUME -- To obtain proper

temperature control, loop fluid volume must be at least 3 gal-

lons per ton (3.25 L per kW) of chiller nominal capacity for air

conditioning and at least 6 gallons per ton (6.5 L per kW) for

process applications or systems that must operate at low ambi-

ent temperatures (below 32 F [0 ° C]). Refer to application in-

formation in Product Data literature for details.

FLOW RATE REQUIREMENTS -- Standard chillers should

be applied with nominal flow rates within those listed in the

Minimum and Maximum Cooler Flow Rates table. Higher or

lower flow rates are permissible to obtain lower or higher

temperature rises. Minimum flow rates must be exceeded to

assure turbulent flow and proper heat transfer in the coolel: See

Table 28. See Fig. 22A-22C for cooler pressure drop curves.

Operation below minimum flow rate could generate

alarms, which could result in &_mage to the coolel:

Consult application &_ta section in the Product Data

literature and job design requirements to determine flow rate

requirements for a particular inst:dlation.

42

Loading...

Loading...