RUN

STATUS

Auto Display

(VIEW)

Remote

User Interface

(R.CCN)

Machine

Starts/Hours

(RUN)

Compressor

Run Hours

(HOUR)

Compressor

Starts

(STRT)

Fan Run

Hours

(FAN)

Compressor

Disable

(CRUN)

Predictive

Maintenance

(MAIN)

Software Versions

(VERS)

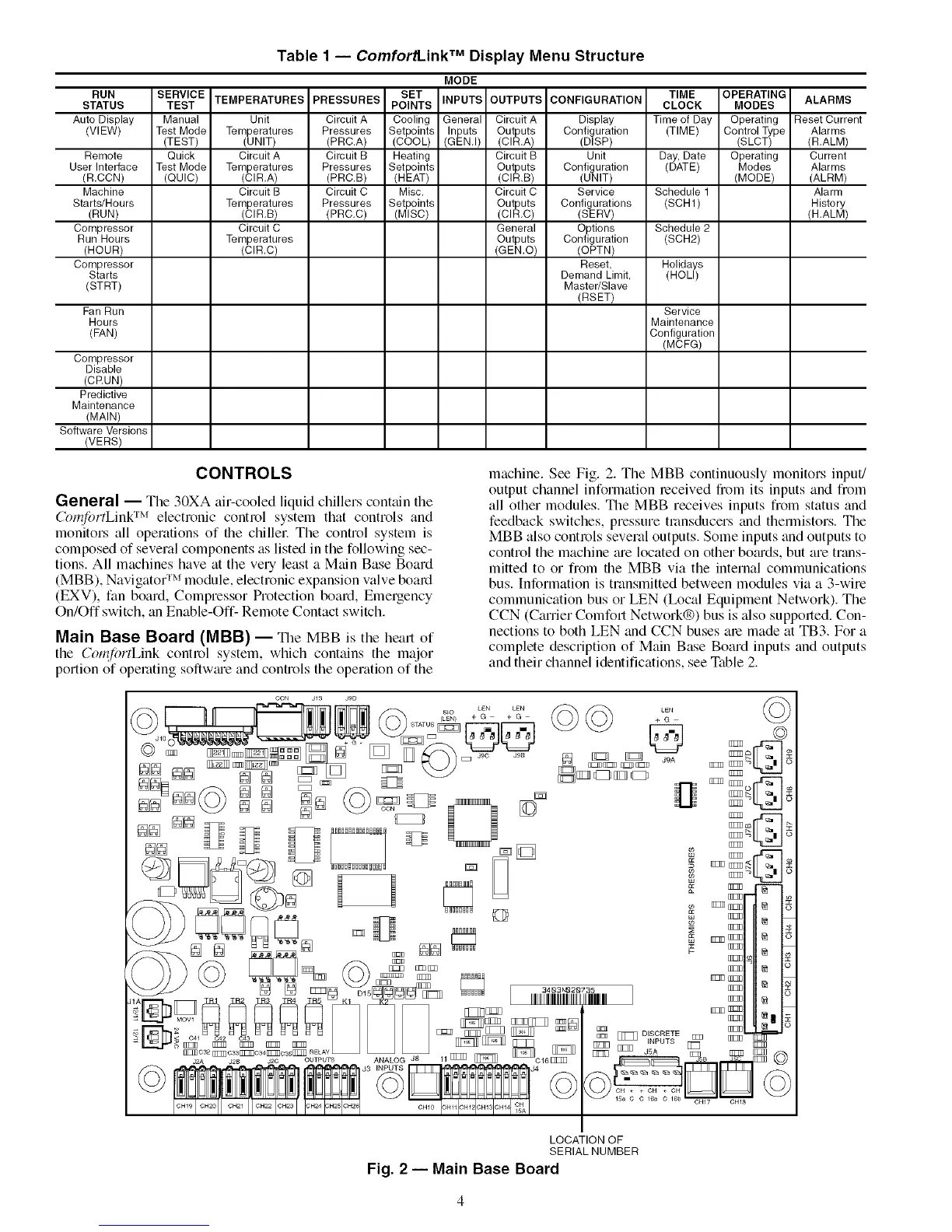

Table 1 -- ComfortLink TM Display Menu Structure

SERVICE TEMPERATURES

TEST

Manual Unit

Test Mode Temperatures

(TEST) (UNIT)

Quick Circuit A

Test Mode Temperatures

(QUIC) (CIR,A)

Circuit B

Temperatures

(CIR,B)

Circuit C

Temperatures

(CIR.C)

MODE

SET INPUTS OUTPUTS CONFIGURATION

PRESSURES POINTS

Circuit A Cooling General Circuit A Display

Pressures Setpoints Inputs Outputs Configuration

(PRC.A) (COOL) (GEM,I) (CIR.A) (DISP)

Circuit B Heating Circuit B Unit

Pressures Setpoints Outputs Configuration

(PRC.B) (HEAT) (CIR.B) (UNIT)

Circuit C Misc. Circuit C Service

Pressures Setpoints Outputs Configurations

(PRC,C) (MISC) (CIR,C) (SERV)

General Options

Outputs Configuration

(GEM.O) (OPTN)

Reset,

Demand Limit,

Master/Slave

(RSET)

TIME

CLOCK

Time of Day

(TIME)

Day, Date

(DATE)

Schedule 1

(SCH1)

Schedule 2

(SCH2)

Holidays

(HOLI)

Service

Maintenance

Configuration

(MCFG)

OPERATING

MODES

Operating

Control Type

(SLCT)

Operating

Modes

(MODE)

ALARMS

Reset Current

Alarms

(R.ALM)

Current

Alarms

(ALRM)

Alarm

History

(H.ALM)

CONTROLS

General -- The 30XA air-cooled liquid chillers contain the

Con_fbrtLink TM electronic control system that controls and

monitors all operations of the chillel: The control system is

composed of several components as listed in the following sec-

tions. All machines have at the ve U least a Main Base Board

(MBB), Navigatoi r_'_module, electronic expansion valve board

(EXV), fan board, Compressor Protection board, Emergency

On/Off switch, an Enable-Off- Remote Contact switch.

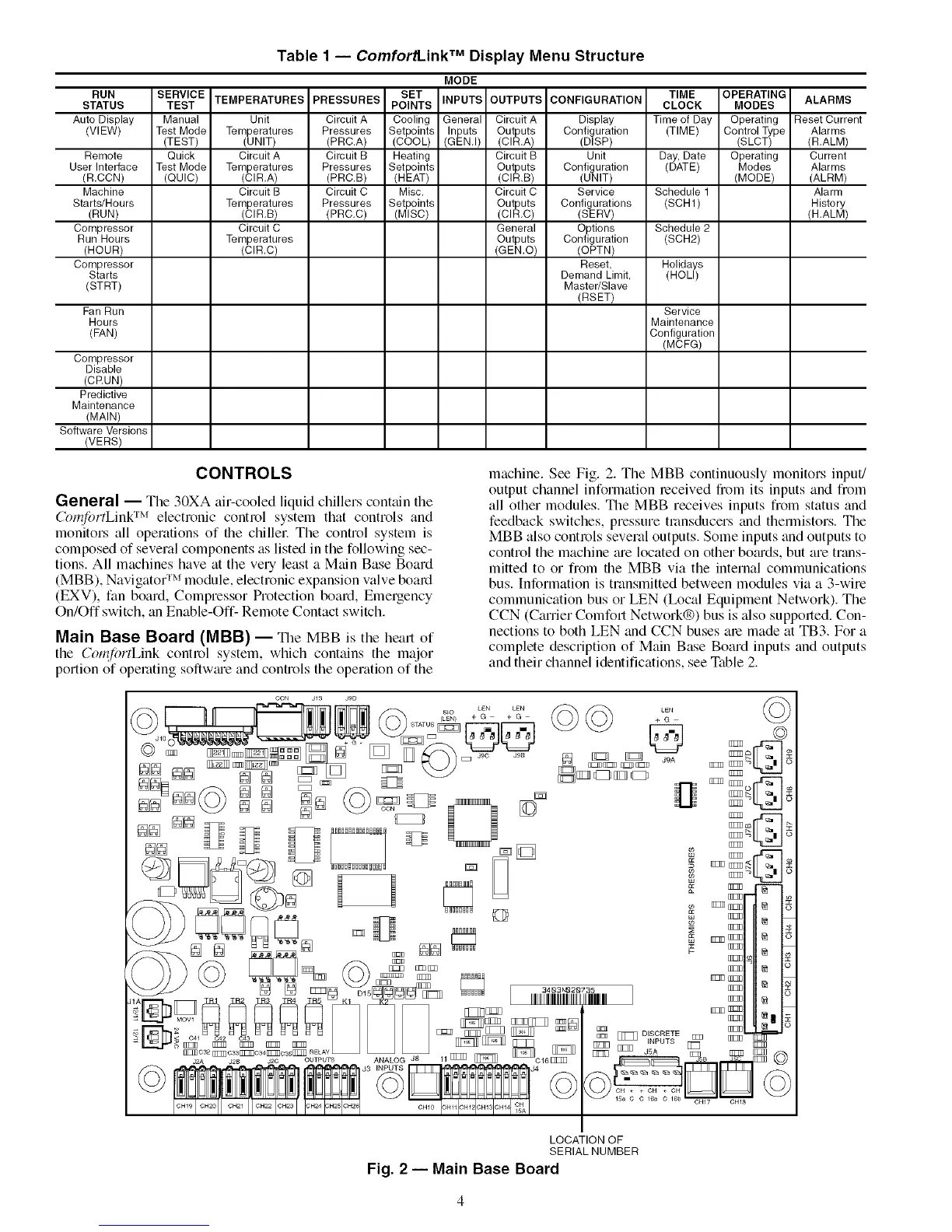

Main Base Board (MBB) -- Tile MBB is tile heart of

the Corqi0rtLink control system, which contains the major

portion of operating softwme and controls the operation of the

machine. See Fig. 2. The MBB continuously monitors input!

output channel information received from its inputs and from

all other modules. The MBB receives inputs from status and

feedback switches, pressure transducers and thermistors. The

MBB also controls several outputs. Some inputs and outputs to

control the machine me located on other bo_uds, but are trans-

mitted to or from the MBB via the internal communications

bus. Information is transmitted between modules via a 3-wire

communication bus or LEN (Ix)cal Equipment Network). The

CCN (Carrier Comfort Network®) bus is also supported. Con-

nections to both LEN and CCN buses are made at TB3. For a

complete description of Main Base Board inputs and outputs

and their channel identifications, see Table 2.

LOCATION OF

SERIAL NUMBER

Fig. 2 -- Main Base Board

Loading...

Loading...