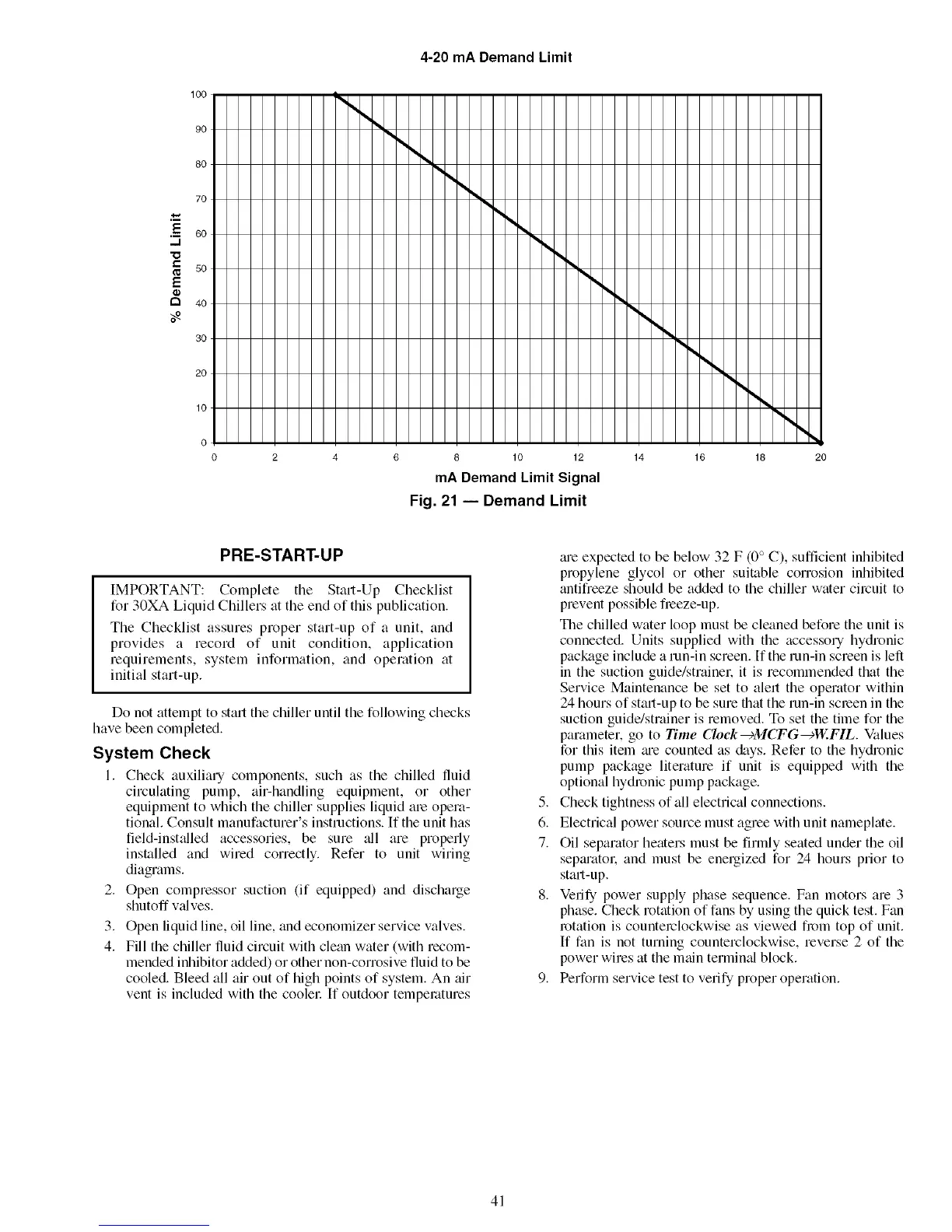

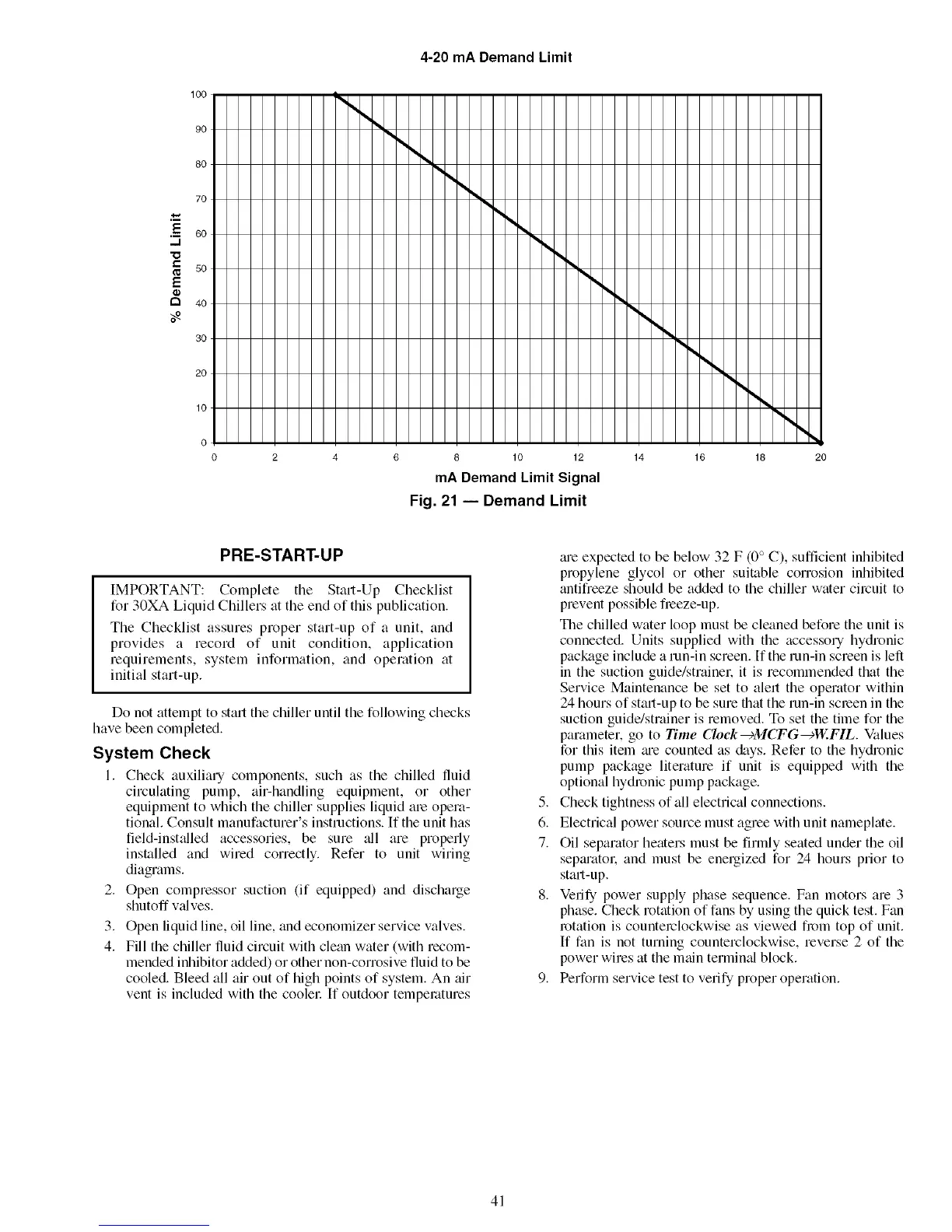

4-20 mA Demand Limit

100

90

80

70

.-_ 60

,,,,,.I

"0

so

E

r"t 40

3O

20

10

I

10 12

mADemand Limit Signal

Fig. 21 -- Demand Limit

14 16 18 2O

PRE-START-UP

IMPORTANT: Complete the Stall-Up Checklist

for 30XA Liquid Chillers at the end of this publication.

The Checklist assures proper start-up of a unit, and

provides a record of unit condition, application

requirements, system information, and operation at

initial start-up.

Do not attempt to start the chiller until the following checks

have been completed.

System Check

I. Check auxiliary components, such as the chilled fluid

circulating pump, air-handling equipment, or other

equipment to which the chiller supplies liquid ale opela-

tional. Consult manufacturer's instructions. If the unit has

field-installed accessories, be sure _11 are properly

installed and wired correctly. Refer to unit wiring

diagrams.

2. Open compressor suction (if equipped) and discharge

shutoff v_dyes.

3. Open liquid line, oil line, and economizer service valves.

4. Fill the chiller fluid circuit with clean water (with recom-

mended inhibitor added) or other non-corrosive fluid to be

cooled. Bleed all air out of high points of system. An air

vent is included with the coolel: If outdoor temperatures

5.

6.

7.

tue expected to be below 32 F (0° C), sufficient inhibited

propylene glycol or other suitable corrosion inhibited

antifreeze should be added to the chiller water circuit to

prevent possible fieeze-up.

The chilled water loop must be cleaned before the unit is

connected. Units supplied with the accessory hydronic

package include a run-in screen. If the run-in screen is left

in the suction guide/strainel: it is recommended that the

Service Maintenance be set to alert the operator within

24 hours of stall-up to be sure that the run-in screen in the

suction guide/strainer is removed. To set the time for the

parameter, go to Time Cloek---)MCFG---)W.FIL. Values

for this item me counted as &tys. Refer to the hydronic

pump package literature if unit is equipped with the

optional hydronic pump package.

Check tightness of all electrical connections.

Electrical power source must agree with unit nameplate.

Oil separator heaters must be firmly seated under the oil

septu'atol: and must be energized for 24 hours prior to

start-up.

Verify power supply phase sequence. Fan motors are 3

phase. Check rotation of fans by using the quick test. Fan

rotation is counterclockwise as viewed from top of unit.

If fan is not turning counterclockwise, reverse 2 of the

power wires at the main terminal block.

Perform service test to verify proper operation.

41

Loading...

Loading...