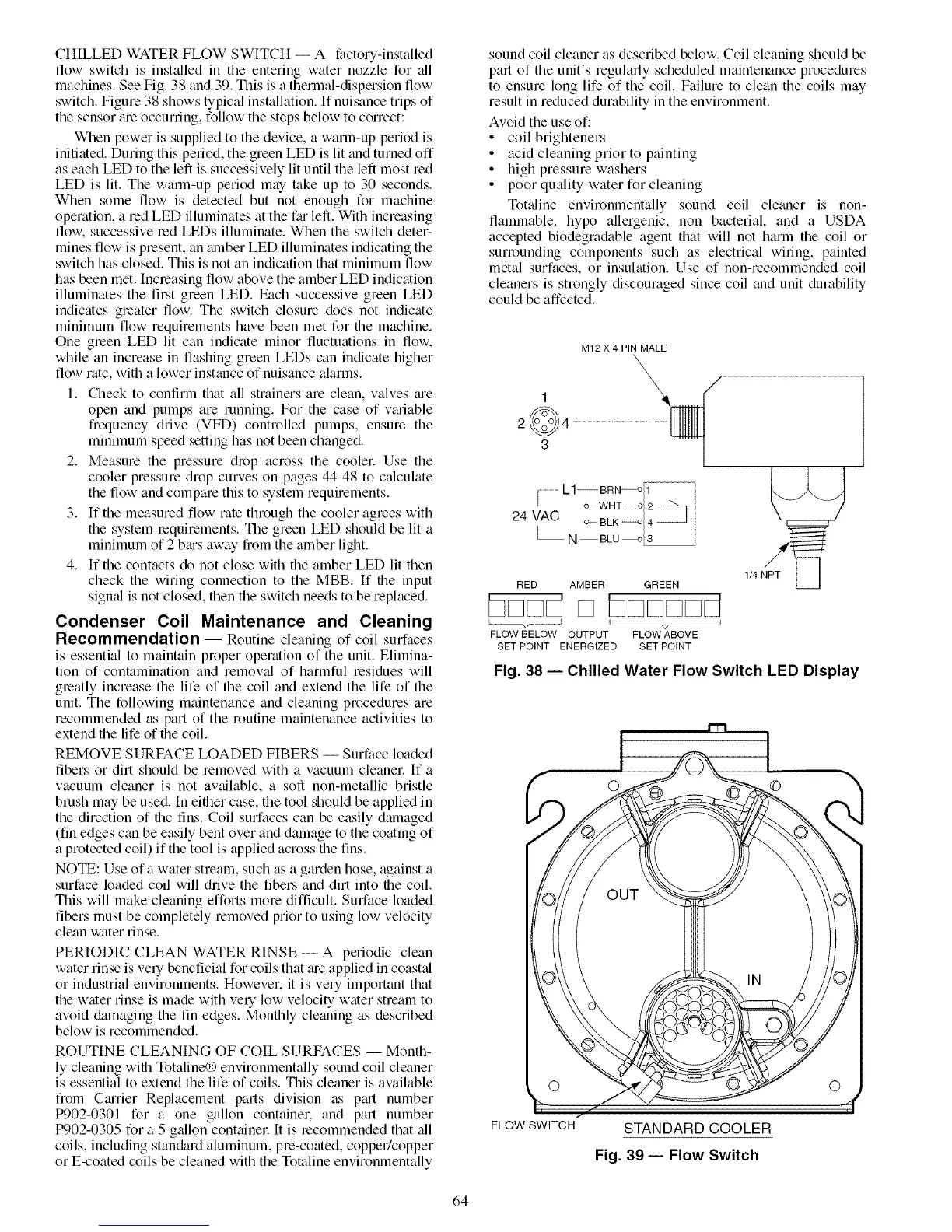

CHILLED WATER FLOW SWITCH -- A factory-installed

flow switch is installed in the entering water nozzle for all

machines. See Fig. 38 and 39. This is a thermal-dispersion flow

switch. Figure 38 shows typical installation. If nuisance trips of

the sensor me occurnng, follow the steps below to correct:

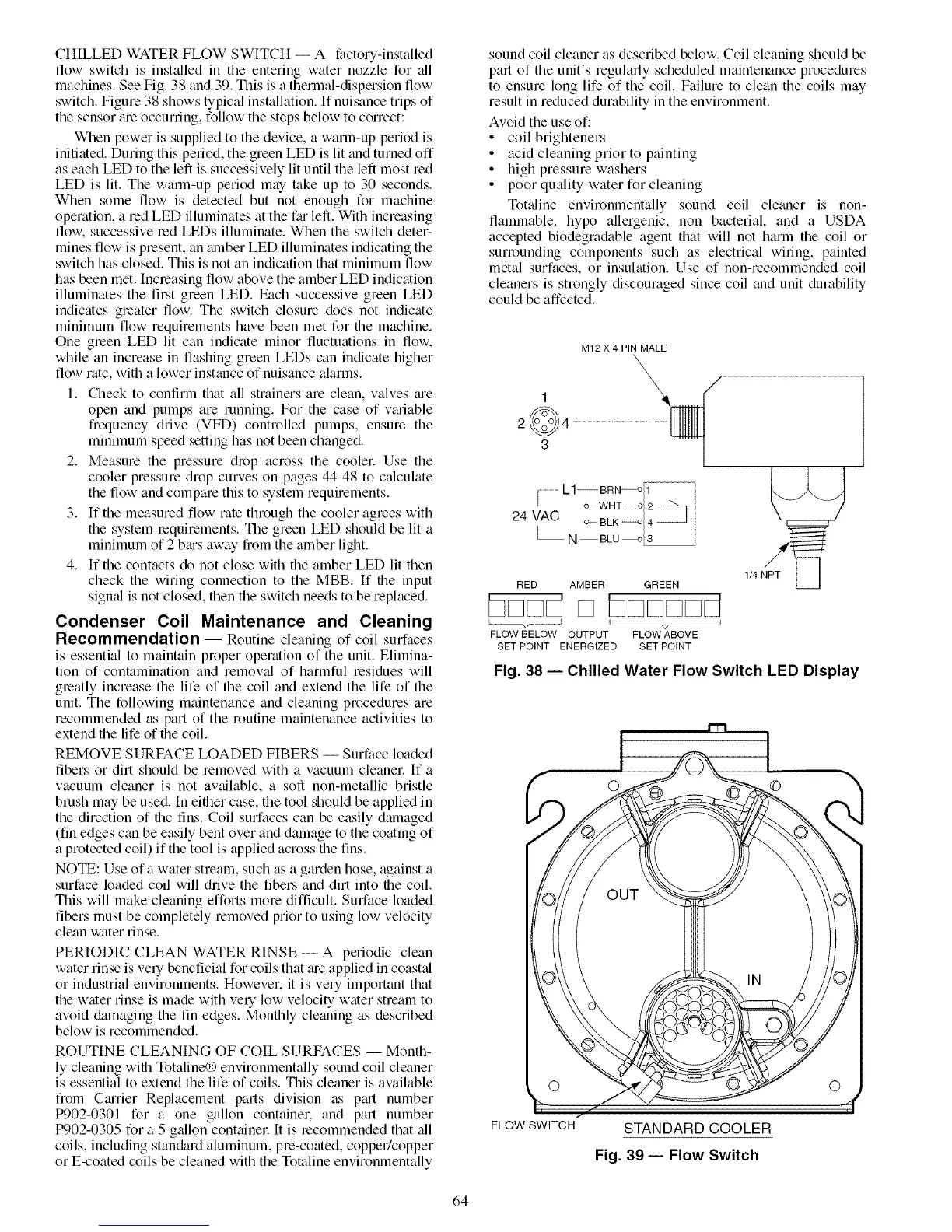

When power is supplied to the device, a warm-up period is

initiated. During this pedod, the green LED is lit trod turned off

as each LED to the left is successively lit until the left most red

LED is lit. The warm-up period may take up to 30 seconds.

When some flow is detected but not enough for machine

operation, a red LED illuminates tit the fro left. With increasing

flow, successive red LEDs illuminate. When the switch deter-

mines flow is present, an amber LED illuminates indicating the

switch has closed. This is not an indication that minimum flow

has been met. Increasing flow above the amber LED indication

illuminates the first green LED. Each successive green LED

indicates greater flow. The switch closure does not indicate

minimum flow requirements have been met for the machine.

One green LED lit can indicate minor fluctuations in flow.

while an increase in flashing green LEDs can indicate higher

flow rate, with a lower instance of nuisance alarms.

1. Check to confirm that all strainers are clean, valves me

open and pumps are running. For the case of vtuiable

frequency drive (VFD) controlled pumps, ensure the

minimum speed setting has not been changed.

2. Measure the pressure drop across the coolel: Use the

cooler pressure drop curves on pages 44-48 to ctdculate

the flow and compare this to system requirements.

3. If the measured flow rate through the cooler agrees with

the system lequirements. The green LED should be lit a

minimum of 2 bras away from the amber light.

4. If the contacts do not close with the amber LED lit then

check the wiring connection to the MBB. If the input

signal is not closed, then the switch needs to be replaced.

Condenser Coil Maintenance and Cleaning

Recommendation -- Routine cleaning of coil surfaces

is essential to maintain proper operation of the unit. Elimina-

tion of contamination and removal of harmful residues will

greatly increase the life of the coil and extend the life of the

unit. The following maintenance and cleaning procedures are

recommended as part of the routine maintenance activities to

extend the life of the coil.

REMOVE SURFACE LOADED FIBERS -- Surface loaded

fibers or dirt should be removed with a vacuum cleanel: If a

vacuum cleaner is not av_filable, a soft non-metallic bristle

brush may be used. In either case, the tool should be applied in

the direction of file fins. Coil surfaces can be easily damaged

(fin edges can be easily bent over and damage to the coating of

a protected coil) if the tool is applied across file fins.

NOTE: Use of a water stream, such as a garden hose, against a

surface loaded coil will drive the fibers and dirt into file coil.

This will make cleaning efforts more dift]cult. Surface loaded

fibers must be completely removed prior to using low velocity

clean water rinse.

PERIODIC CLEAN WATER RINSE -- A periodic clean

water rinse is very beneficial for coils that me applied in coastal

or industrial environments. Howevel, it is very important that

the water rinse is made with ve q low velocity water stream to

avoid &imaging the fin edges. Monthly cleaning as described

below is recommended.

ROUTINE CLEANING OF COIL SURFACES -- Month-

ly cleaning wifll Totaline® environmentally sound coil cleaner

is essential to extend the life of coils. This cleaner is available

from Carrier Replacement parts division as ptut number

tx)02-0301 for a one gallon container, and part number

tx)02-0305 for a 5 gallon conttfiner It is lecommended that tdl

coils, including stan&trd aluminum, pre-coated, copper/copper

or E-coated coils be cleaned with the Totaline environmentally

sound coil cleaner as described below. Coil cleaning should be

part of the unit's regularly scheduled maintenance procedures

to ensure long life of the coil. Failure to clean the coils may

result in reduced durability in the environment.

Avoid the use of:

• coil brighteners

• acid cleaning prior to painting

• high pressure washers

• poor quality water for cleaning

Tottdine environmentally sound coil cleaner is non-

flammable, hypo allergenic, non bacterial, and a USDA

accepted biodegra&tble agent that will not harm the coil or

surrounding components such as electrical wiring, painted

metal surfaces, or insulation. Use of non-recommended coil

cleaners is strongly discouraged since coil and unit durability

could be affected.

M12 X 4 PIN MALE

1

2@4

3

......................L1--BRN----o/i _............................................

I c_ WHT---o 2--

24 VAC _BLK__OI_ _

N B,u i

RED AMBER GREEN

I 1 I I

.................................v ..................................I I _ J

FLOW BELOW OUTPUT FLOW ABOVE

SET POINT ENERGIZED SET POINT

Fig. 38 -- Chilled Water Flow Switch LED Display

FLOW SWITCH STANDARD COOLER

Fig. 39 -- Flow Switch

64

Loading...

Loading...