PREFIX

CODE

P

SUFFIX

CODE

4O

41

42

43

73

74

78

79

8O

81

82

83

87

88

89

9O

91

ALARM

NUMBER

93

94

95

96

97

98

99

100

101

1O2

1O3

1O4

1O5

1O6

1O7

1O8

1O9

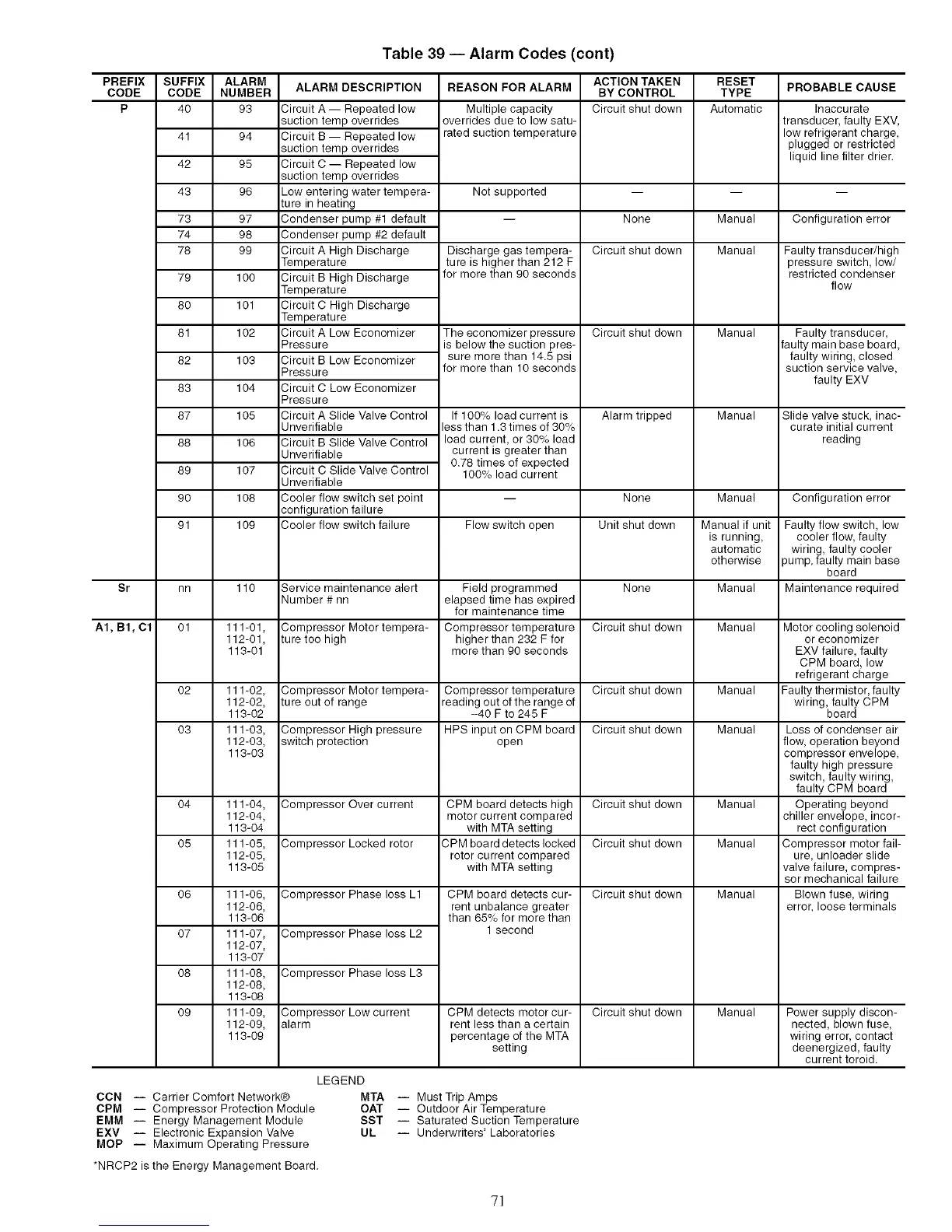

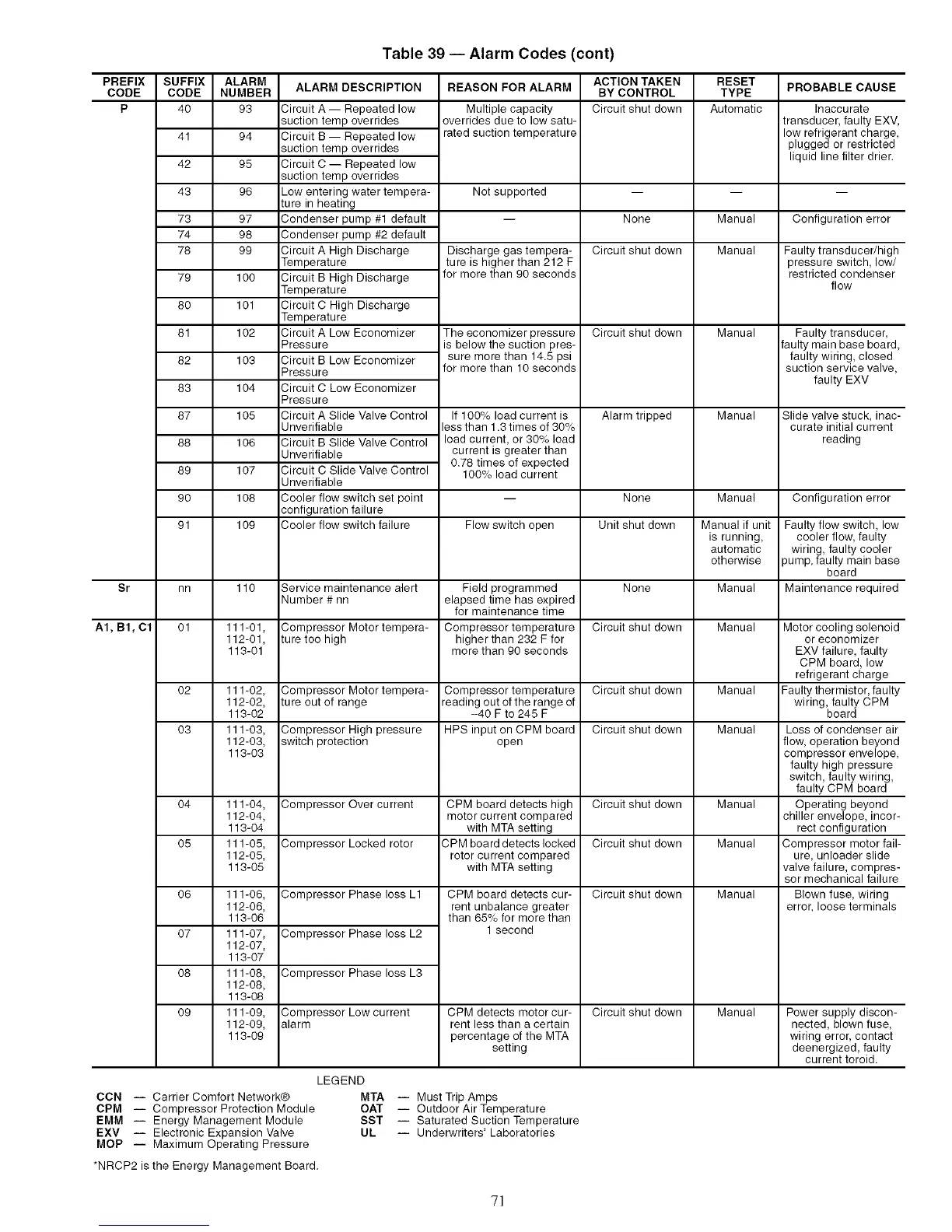

Table 39 -- Alarm Codes (cont)

ALARM DESCRIPTION

Circuit A -- Repeated low

suction temp overrides

Circuit B -- Repeated low

suction temp overrides

Circuit C -- Repeated low

suction temp overrides

Low entering water tempera-

ture in heating

Condenser pump #1 default

Condenser pump #2 default

Circuit A High Discharge

Temperature

Circuit B High Discharge

Temperature

Circuit C High Discharge

Temperature

Circuit A Low Economizer

Pressure

Circuit B Low Economizer

Pressure

Circuit C Low Economizer

Pressure

Circuit A Slide Valve Control

Unverifiable

Circuit B Slide Valve Control

Unverifiable

Circuit C Slide Valve Control

Unverifiable

Cooler flow switch set point

configuration failure

Cooler flow switch failure

REASON FOR ALARM

Multiple capacity

overrides due to low satu-

rated suction temperature

ACTION TAKEN

BY CONTROL

Circuit shut down

RESET

TYPE

Automatic

PROBABLE CAUSE

Inaccurate

transducer, faulty EXV,

low refrigerant charge,

plugged or restricted

liquid line filter drier.

Not supported

-- Configuration error

None

Circuit shut down

Circuit shut down

Discharge gas tempera-

ture is higher than 212 F

for more than 90 seconds

Alarm tripped

Manual

Manual

Manual

Manual

The economizer pressure

is below the suction pres-

sure more than 14.5 psi

for more than 10seconds

If 100% load current is

less than 1.3 times of 30%

load current, or 30% load

current is greater than

0.78 times of expected

100% load current

Faulty transducer/high

pressure switch, low/

restricted condenser

flow

Faulty transducer,

faulty main base board,

faulty wiring, closed

suction service valve,

faulty EXV

CPM board detects cur-

rent unbalance greater

than 65% for more than

1 second

Slide valve stuck, inac-

curate initial current

reading

-- None Manual Configuration error

Flow switch open Unit shut down Manual if unit Faulty flow switch, low

is running, cooler flow, faulty

automatic wiring, faulty cooler

otherwise pump, faulty main base

board

Sr nn 110 Service maintenance alert Field programmed None Manual Maintenance required

Number # nn elapsed time has expired

for maintenance time

A1, B1, Cl 01 111-01, Compressor Motor tempera- Compressor temperature Circuit shut down Manual Motor cooling solenoid

112-01, ture too high higher than 232 F for or economizer

113-01 more than 90 seconds EXV failure, faulty

CPM board, low

refrigerant charge

02 111-02, Compressor Motor tempera- Compressor temperature Circuit shut down Manual Faulty thermistor, faulty

112-02, ture out of range reading out of the range of wiring, faulty CPM

113-02 -40 F to 245 F board

03 111-03, Compressor High pressure HPS input on CPM board Circuit shut down Manual Loss of condenser air

112-03, switch protection open flow, operation beyond

113-03 compressor envelope,

faulty high pressure

switch, faulty wiring,

faulty CPM board

04 111-04, Compressor Over current CPM board detects high Circuit shut down Manual Operating beyond

112-04, motor current compared chiller envelope, incor-

113-04 with MTA setting rect configuration

05 111-05, Compressor Locked rotor CPM board detects locked Circuit shut down Manual Compressor motor fail-

112-05, rotor current compared ure, unloader slide

113-05 with MTA setting valve failure, compres-

sor mechanical failure

Circuit shut down Manual Blown fuse, wiring

error, loose terminals

06 111-06,

112-06,

113-06

07 111-07,

112-07,

113-07

08 111-08,

112-08,

113-08

09 111-09,

112-09,

113-09

Compressor Phase loss L1

Compressor Phase loss L2

Compressor Phase loss L3

Compressor Low current CPM detects motor cur- Circuit shut down Manual Power supply discon-

alarm rent less than a certain nected, blown fuse,

percentage of the MTA wiring error, contact

setting deenergized, faulty

current toroid.

-- Must Trip Amps

-- Outdoor Air Temperature

-- Saturated Suction Temperature

-- Underwriters' Laboratories

LEGEND

CON i Carrier Comfort Network® MTA

CPM -- Compressor Protection Module OAT

EMM -- Energy Management Module SST

EXV -- Electronic Expansion Valve UL

MOP -- Maximum Operating Pressure

*NRCP2 is the Energy Management Board.

71

Loading...

Loading...