14

4. Clean coil using a commercial coil cleaner or dish-

washer detergent in a pressurized spray canister. Wash

both sides of coil and flush with clean water. For best

results, back --flush toward return--air section to re-

move foreign material. Flush c ondensate pan after

completion.

5. Reinstall economizer and filters.

6. Reconnect wiring.

7. Replace access panels.

THERMOSTATIC EXPANSION

VALVE (TXV)

All 50HC’s have a factory installed nonadjustable

thermostatic expansion valve (TXV). The TXV will be a

bi-flow, bleed port expansion val ve with an externa l

equalizer. TXVs are specificall y designed to operate with

PuronR or R-22 refrigera nt, use only factory authoriz ed

TXVs. Do not interchange Puron and R-22 TXVs.

TXV Operation

The TXV is a metering device that is used in air

conditioning and heat pump systems to adjust to the

changing load conditions by maintaining a preset

superheat t emperature at the outlet of the evaporator coil.

The volume of refri gerant met ered through the valve seat

is dependent upon the following:

1. Superheat temperature is sensed by cap tube sensing

bulb on suction tube at outlet of evaporator coil. This

temperature is converted into pressure by refrigera nt

in the bulb pushing downward on the diaphragm

which opens the valve using the push rods.

2. The suction pressure at the outlet of the evaporator

coil is transferred through the external equalizer tube

to the underside of the diaphragm .

3. The pin is spring loaded, which exerts pressure on the

underside of the diaphragm. Therefore, the bulb pres-

sure works against the spring pressure and evaporator

suction pressure to open the valve. If the load in-

creases, the temperature increases at the bulb, which

increases the pressure on the top side of the dia-

phragm. This opens the valve and i ncreases the flow

of refrigerant. The increased refrigerant flow c auses

the leaving evaporator temperature to decrease. This

lowers the pressure on the diaphragm and closes the

pin. The refrigerant flow is effectively stabilized to

the load demand with negligible change in superheat.

Replacing TXV

1. Recover refrigerant.

2. Remove T XV support clam p using a 5/l6-in. nut

driver.

3. Remove T XV using a wrench and an additional

wrench on connections to prevent damage to tubing.

4. Remove equalizer tube from suction line of coil. Use

file or tubing cutter to cut brazed equalizer line

approximately 2 inches above suction tube.

5. Remove bulb from vapor tube inside cabinet.

6. Install the new TXV using a wrench and an additional

wrench on connections to prevent damage to tubing

while attaching TXV to distributor.

7. Attach the equalizer tube to the suction line. If the

coil has mechanical a connection, then use a wrench

and an addit ional wrench on connections to prevent

damage. If t he coil has a brazed connection, use a file

or a tubing cutter to remove the mechanical flare nut

from the equalizer line. Then use a new coupling to

braze the equali zer line to the stub (previous equalizer

line) in suction line.

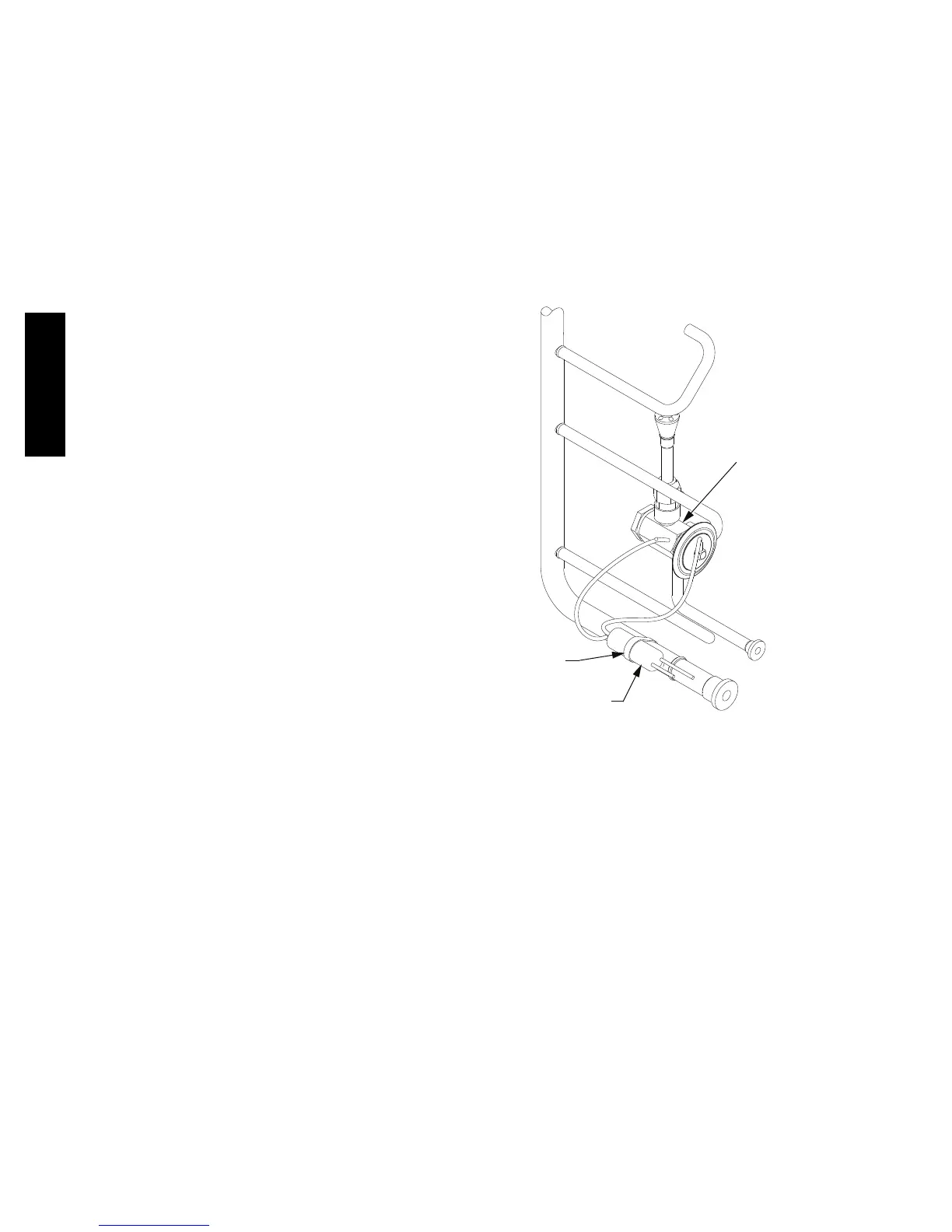

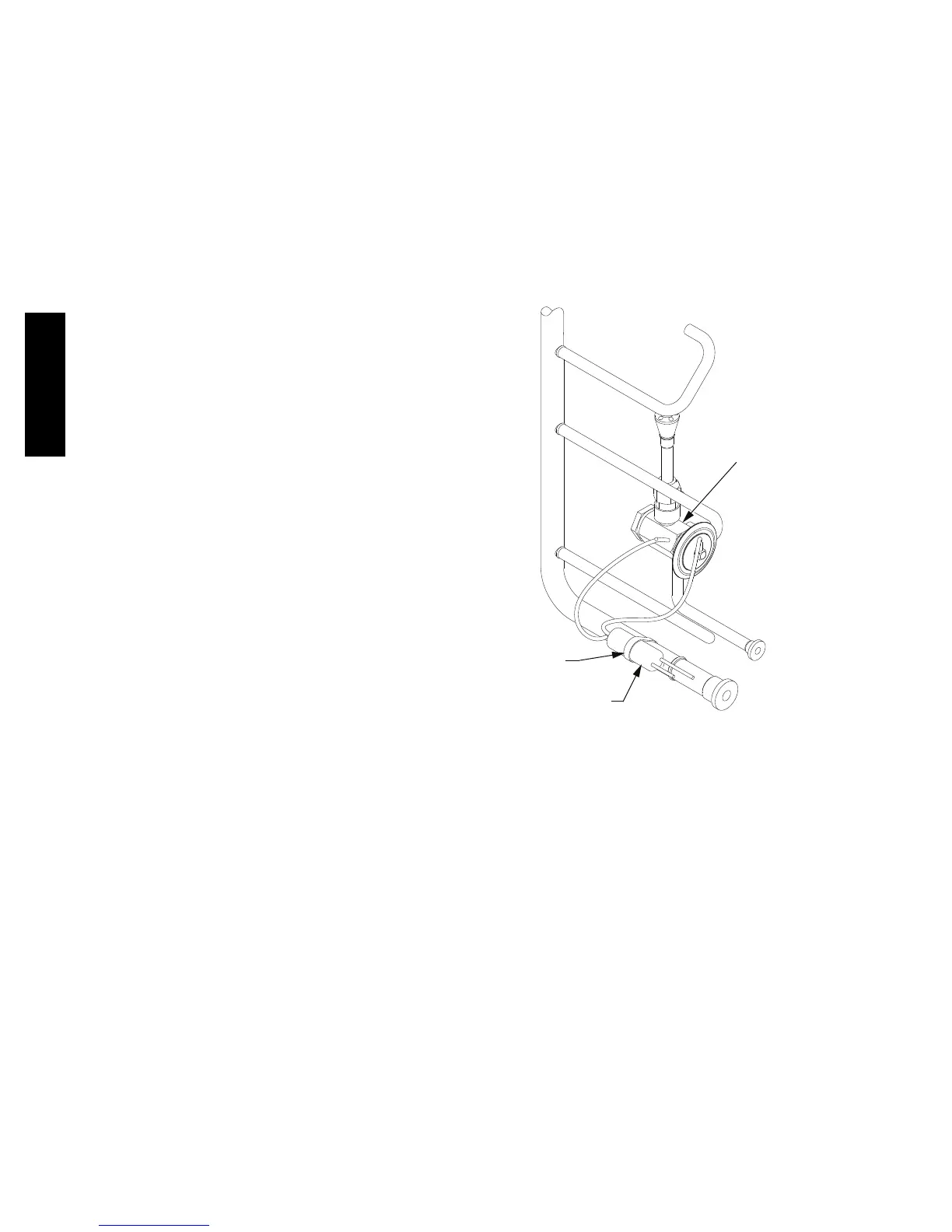

8. Attach TXV bulb in the same location where the ori-

ginal (in the sensing bulb indent) was when it was re-

moved, using the supplied bulb clamps. See Fig. 17.

TXV SENSING

BULB

CLAMP

THERMAL EXPANSION

(TXV) VALVE

SENSING BULB INSULATION REMOVED FOR CLARITY

C10372

Fig. 17 -- TXV Valve and Sensing Bulb Location

9. Route equalizer tube through suction connection

opening (large hole) in fitting panel and install fitting

panel in place.

10. Sweat the inlet of TXV marked “IN” to the liquid

line. Avoid excessive heat which could damage the

TXV valve. Use quenching cloth when applying heat

anywhere on TXV.

Refrigerant System Press ure Access Ports

There are two access ports in the system -- on the suction

tube near the compressor and on the discharge t ube near

the compressor. These are brass fittings with black plastic

caps. The hose connection fittings are standard 1/4 SAE

male flare couplings.

The brass fittings are two--piece High Flow valves, with a

receptacle base brazed to the tubing and an integral

spring--closed check valve core screwed into the base. See

Fig. 18. This check valve is permanently assembled into

this core body and cannot be serviced separately; repla ce

50HC

Loading...

Loading...