5

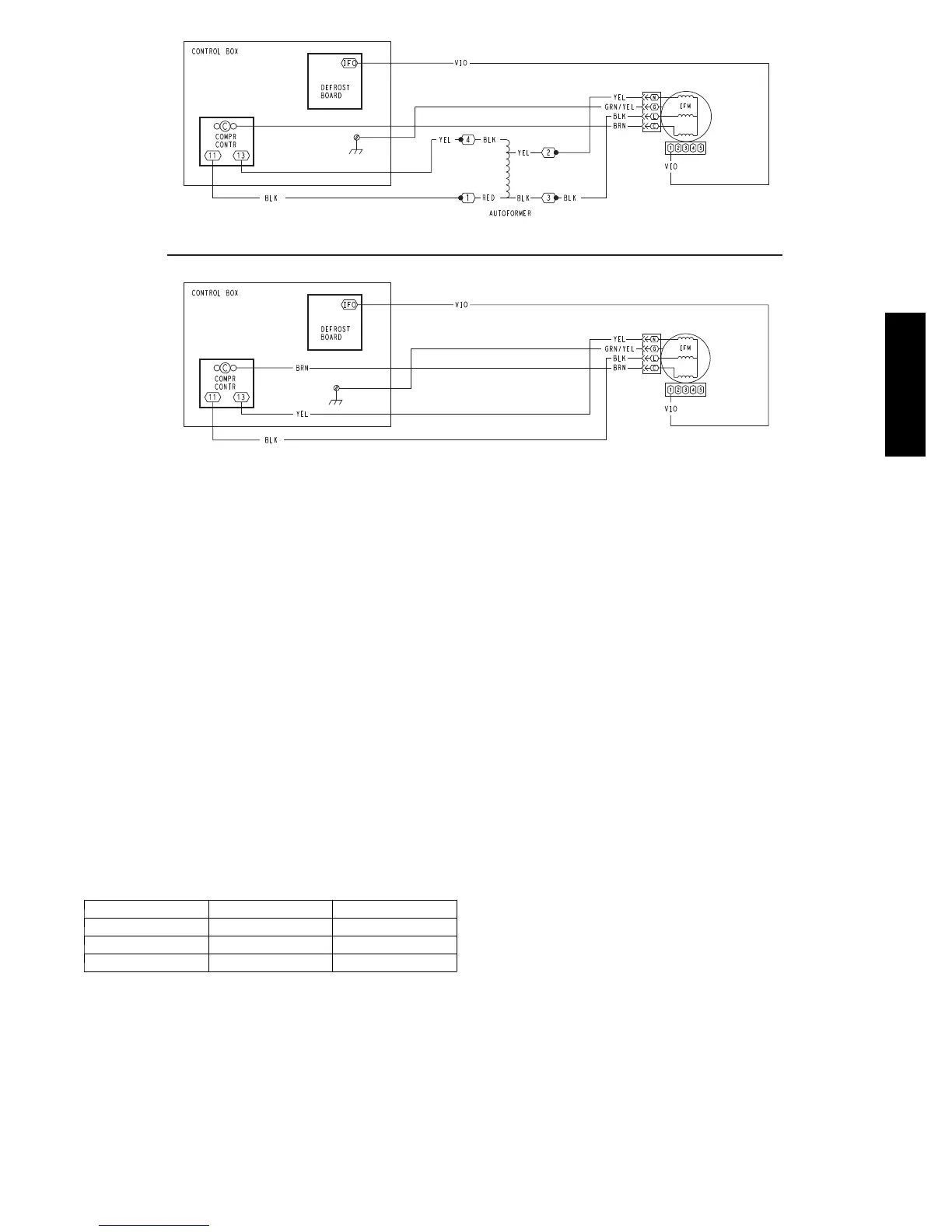

460, 575-v Units

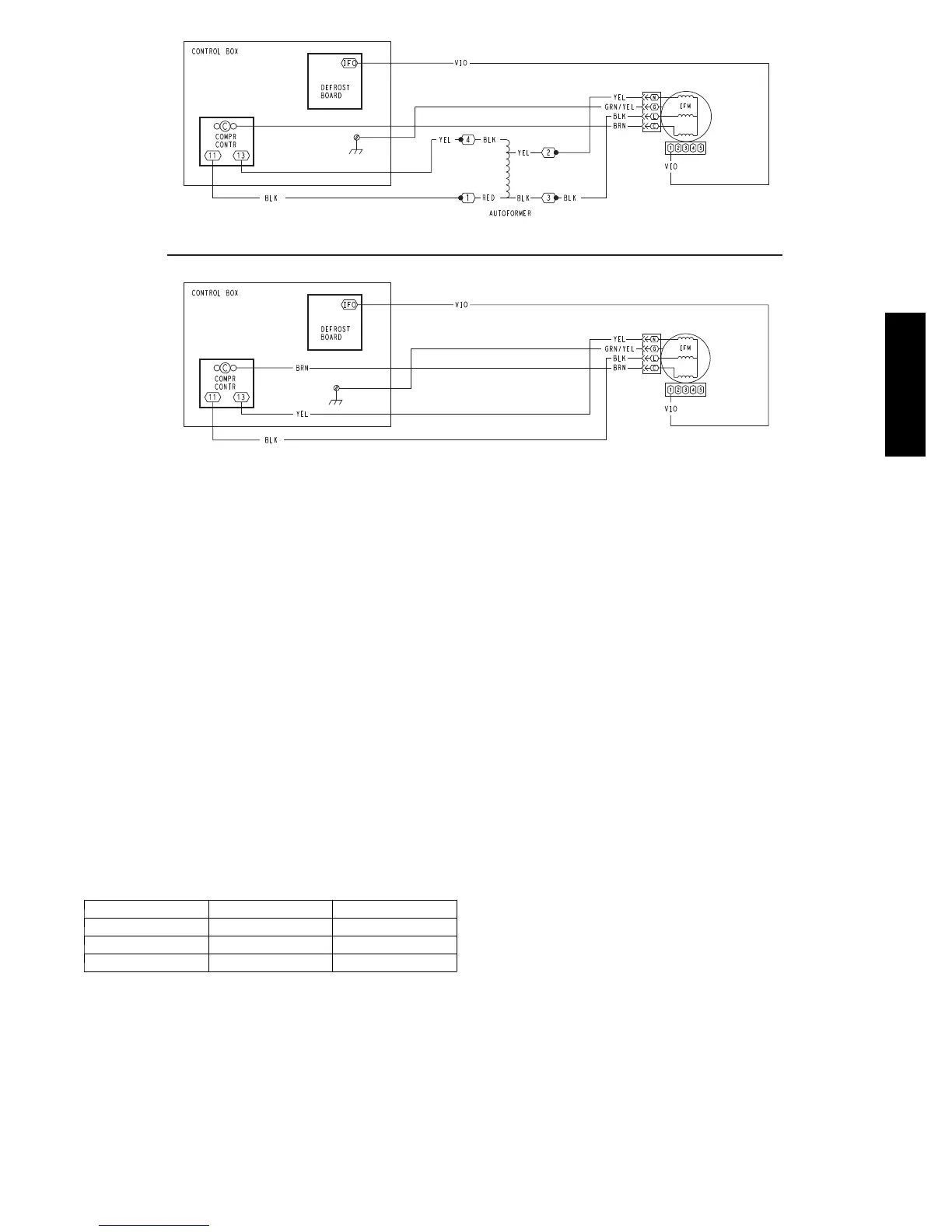

208/230-v Units

C09260

Fig. 5 -- Direct--Drive Supply Fan Assembly

Motor “rocking” on star t--up — When the motor first

starts, the rotor (and attached wheel) will “rock” back and

forth as the motor tests for rotational direction. Once the

correct rotational direction is determined by the motor

circuitry, the motor will ramp up to the specified speed.

The “rocking” is a normal operating characteristic of

ECM motors.

Troubleshooting the ECM motor — Troubleshooti ng the

X13 ECM requires a voltmeter.

1. Disconnect main power to the unit.

2. Remove the motor power plug (including the control

BRN l ead) and VIO control signal lead at the motor

terminals.

3. Restore main unit power.

4. Check for proper line voltage at motor power leads

BLK (at L terminal) and YEL (at N terminal). See

Table 2.

Table 2 – Motor Test Volts

Unit Voltage Motor Voltage Min---Max Volts

208/230 230 190--- 250

460 230 210--- 250

575 460 420--- 500

5. Using a jumper wire from unit control terminals R to

G, engage motor operation. Check for 24v output at

the defrost board terminal IFO.

6. Check for proper c ontrol signal voltages of 22V to

28V at motor signal leads VIO and BRN.

7. Disconnect unit main power. Apply lockout/tagout

procedure s.

8. Reconnect m otor power and control signal leads at

the motor terminals.

9. Restore unit main power.

10. The motor should start and run. If the motor does not

start, remove the motor assembly. Replace the motor

with one having t he same part number. Do not

substitute with an alternate design motor as the

torque/ speed programming will not be the same as

that on an origi nal factory motor.

Replacing the X--13 ECM Motor — Before removing

the ECM belly --band mounting ring from old motor:

1. Measure the distance from base of the motor shaft to

the edge of the mounting ring.

2. Remove the motor mounting band and transfer it to

the replacement motor.

3. Position the mounting band at the same distance that

was measured in Step 1.

4. Hand--tighten mounting bolt onl y. Do not tighte n

securely at this time.

5. Insert the motor shaft into the fan wheel hub.

6. Securely tighten the three motor mount arms to the

support cushions and torque the arm mounting screws

to 60 in--lbs (6.8 Nm).

7. Center the fan wheel in the fan housing. Tighten the

fan wheel hub setscrew and torque to 120 in--lbs (13.6

Nm).

8. Ensure the motor terminals are located at a position

below the 3 o’clock position (see Fig. 3). Tighten the

motor be lly--band bolt and torque to 80 in--lbs (9.0

Nm).

Supply Fan (Belt--Drive)

The belt--drive supply fan system consists of a

forward--curved centrifugal blower wheel on a solid shaft

with two concentric type bearings, one on each side of the

50HC

Loading...

Loading...