30

Dirty Sensor Test Procedure

1. Hold the test magnet where indicated on the side of

the sensor housing for two seconds.

2. Verify that the sensor’s Dirty LED flashes.

OPERATIONAL TEST ALERT

Failure to follow this ALERT can result in an

unnecessary evacuation of the facility.

Changing the dirty sensor test operation will put the

detector into the alarm state and activate all automatic

alarm responses. Before changing dirty sensor test

operation, disconnect all auxiliary equipment from the

controller and notify the proper authorities if

connected to a fire alarm system.

NOTICE

Changing the Dirt Sensor Test

By default , sensor dirty test results are indicated by:

S The sensor ’s Dirty LED flashing.

S The controller’s Trouble LED flashing.

S The controller’s supervision rel ay contacts toggle.

The operat ion of a sensor’s dirty test can be changed so

that the controller ’s supervision relay is not used to

indicate test results. When two detectors are connected to

a controller, sensor dirty test operation on both sensors

must be configure d to ope rate in the same manner.

To Configure the Dirty Sensor Test Operation

1. Hold the test magnet where indicated on the side of

the sensor housing until the sensor’s Alarm LED turns

on and its Dirty LED flashes twice (approximately 60

seconds).

2. Reset the sensor by removing the test magnet then

holding it against the sensor housing aga in until the

sensor’s Alarm LED turns off (approximately 2

seconds).

Remote Station Test

The remote station alarm test checks a test/reset station’s

ability to initiate and indicate an alarm state.

OPERATIONAL TEST ALERT

Failure to follow this ALERT can result in an

unnecessary evacuation of the facility.

This test places the duct detector into the alarm state.

Unless part of the test, disconnect all auxiliary

equipment from the controller before performing the

test. If the duct detector is connected to a fire alarm

system, notify the proper authorities before

performing the test.

NOTICE

SD--TRK4 Remote Alarm Test Procedure

1. Turn the key switch to the RESET/TEST position for

seven seconds.

2. Verify that the test/reset station’s Alarm LED turns

on.

3. Reset the sensor by turning the key switch t o the

RESET/TEST position for two seconds.

4. Verify that the test/reset station’s Alarm LED turns

off.

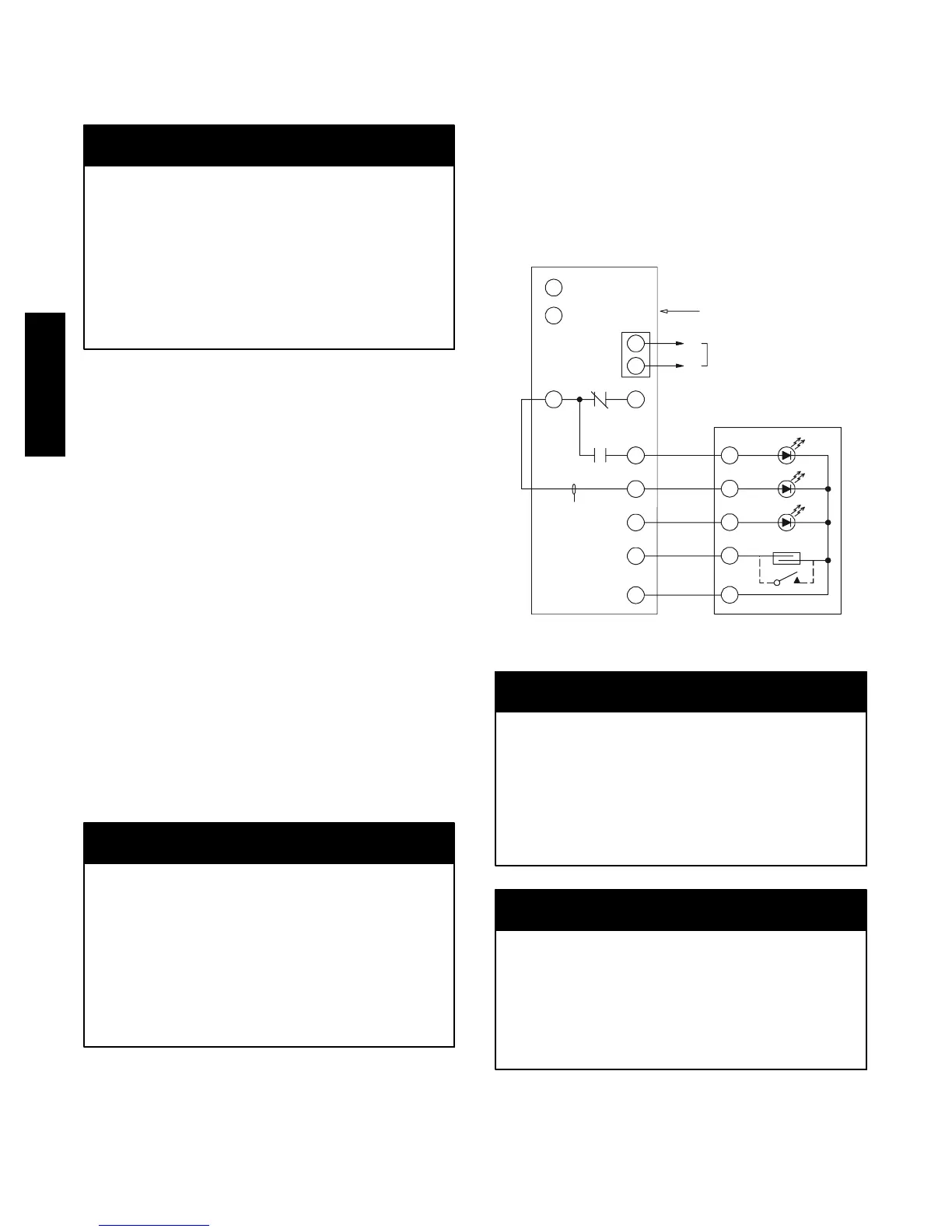

Remote Test/Reset Station Dirty Sensor Test

The test/reset station dirty sensor test checks the test/reset

station’s ability to initiate a sensor dirty test and indicate

the results. It must be wired to the controller as shown in

Fig. 39 and configured to operate the controll er’s

supervision relay. For more information, see “Changing

sensor dirty test operation.”

1

12

14

1

3

19

15

2

20

3

Reset/Test

Trouble

P

ower

Alarm

S

upe

rv

ision relay

contacts [3]

5

4

1

3

2

SD-TRK4

2

1

TB3

18 Vdc ( )

+

18 Vdc ( )

−

Auxiliary

equipment

+

−

W

ire must be

added by installer

Smoke Detector Controller

C08247

Fig. 39 -- Remote Test/Reset Station Connections

OPERATIONAL TEST ALERT

Failure to follow this ALERT can result in an

unnecessary evacuation of the facility.

If the test/reset station’s key switch is left in the

RESET/TEST position for longer than seven seconds,

the detector will automatically go into the alarm state

and activat e all automatic alarm responses.

NOTICE

OPERATIONAL TEST ALERT

Failure to follow this ALERT can result in an

unnecessary evacuation of the facility.

Holding the test magnet to the target area for longer

than se ven seconds will put the detector into the alarm

state a nd a ctivate all automatic alarm responses.

NOTICE

Dirty Sensor Test Using an SD--TRK4

1. Turn the key switch to the RESET/TEST position for

two seconds.

50HC

Loading...

Loading...