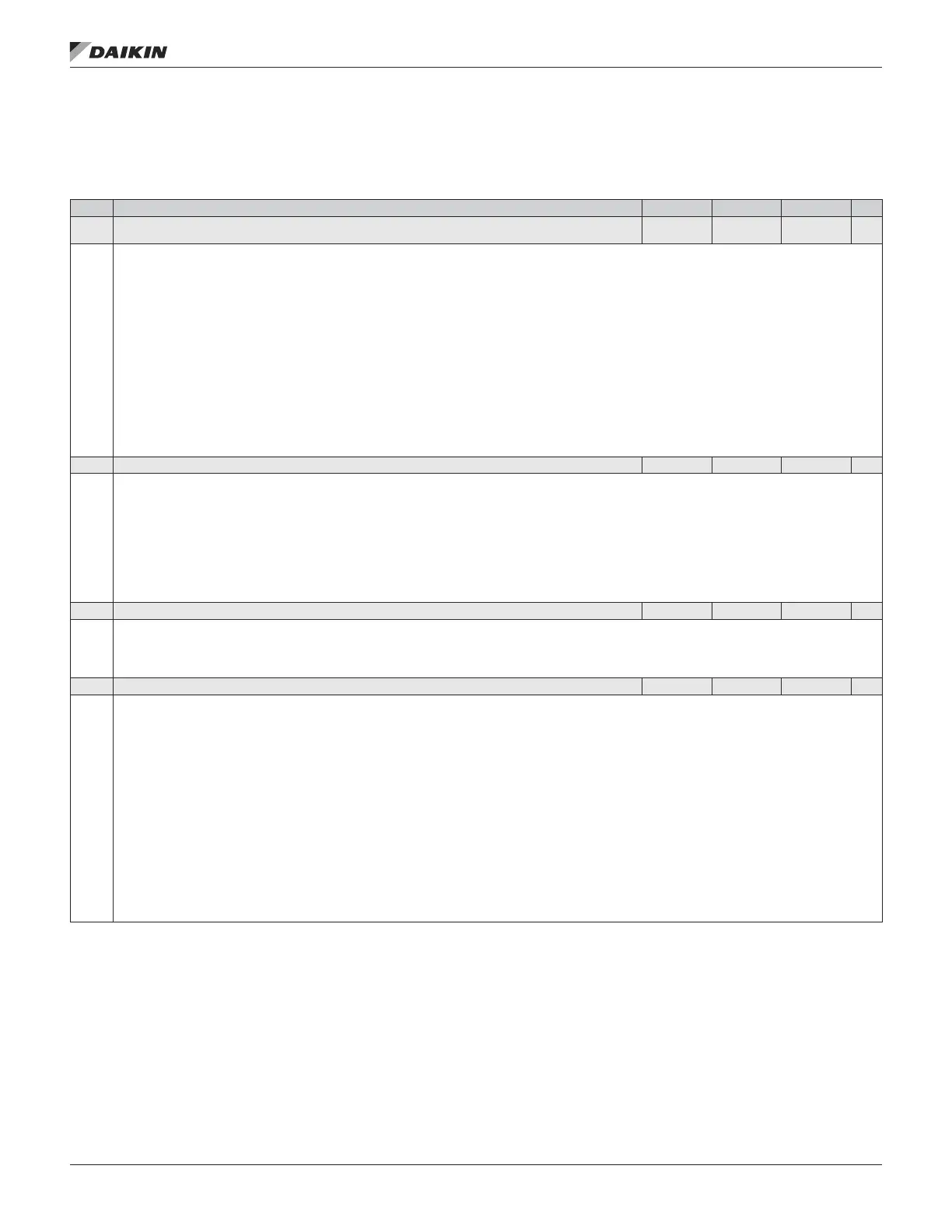

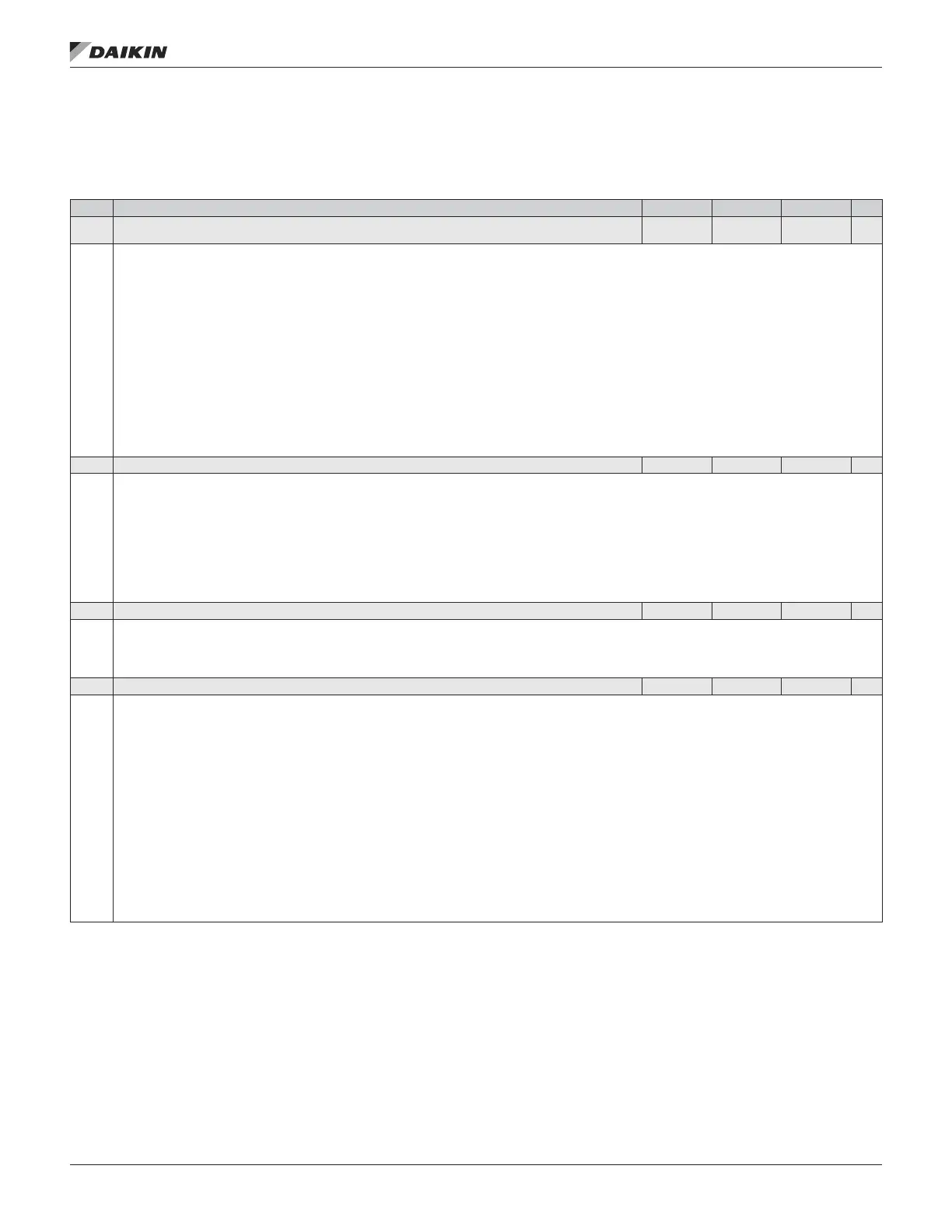

Group 16: System Controls

This group denes a variety of system level locks, resets and enables.

Table 31: Group 16: System Controls

Code Description Range Resolution Default S

1601 RUN ENABLE -6…7 1 0

Selects the source of the run enable signal.

0 = NOT SEL – Allows the drive to start without an external run enable signal.

1 = DI1 – Denes digital input DI1 as the run enable signal.

• This digital input must be activated for run enable.

• If the voltage drops and de-activates this digital input, the drive will coast to stop and not start until the run enable signal resumes.

2…6 = DI2…DI6 – Denes digital input DI2…DI6 as the run enable signal.

• See DI1 above.

7 = COMM – Assigns the eldbus Command Word as the source for the run enable signal.

• Bit 6 of the Command Word 1 (parameter 0301) activates the run disable signal.

• See eldbus user’s manual for detailed instructions.

-1 = DI1(INV) – Denes an inverted digital input DI1 as the run enable signal.

• This digital input must be de-activated for run enable.

• If this digital input activates, the drive will coast to stop and not start until the run enable signal resumes.

-2…-6 = DI2(INV)…DI6(INV) – Denes an inverted digital input DI2…DI6 as the run enable signal.

• See DI1(INV) above.

1602 PARAMETER LOCK 0…2 1 1

Determines if the control panel can change parameter values.

• This lock does not limit parameter changes made by macros.

• This lock does not limit parameter changes written by eldbus inputs.

• This parameter value can be changed only if the correct pass code is entered. See parameter 1603, PASS CODE.

0 = LOCKED – You cannot use the control panel to change parameter values.

• The lock can be opened by entering the valid pass code to parameter 1603.

1 = OPEN – You can use the control panel to change parameter values.

2 = NOT SAVED – You can use the control panel to change parameter values, but they are not stored in permanent memory.

• Set parameter 1607 PARAM SAVE to 1 (SAVE) to store changed parameter values to memory.

1603 PASS CODE 0…65535 1 0

Entering the correct pass code allows you to change the parameter lock.

• See parameter 1602 above.

• The code 358 allows you to change the value of the parameter 1602 once.

• This entry reverts back to 0 automatically.

1604 FAULT RESET SEL -6…8 1 0

Selects the source for the fault reset signal. The signal resets the drive after a fault trip if the cause of the fault no longer exists.

0 = KEYPAD – Denes the control panel as the only fault reset source.

• Fault reset is always possible with control panel.

1 = DI1 – Denes digital input DI1 as a fault reset source.

• Activating the digital input resets the drive.

2…6 = DI2…DI6 – Denes digital input DI2…DI6 as a fault reset source.

• See DI1 above.

7 = START/STOP – Denes the Stop command as a fault reset source.

• Do not use this option when elbus communication provides the start, stop and direction commands.

8 = COMM – Denes the eldbus as a fault reset source.

• The Command Word is supplied through eldbus communication.

• The bit 4 of the Command Word 1 (parameter 0301) resets the drive.

-1 = DI1(INV) – Denes an inverted digital input DI1 as a fault reset source.

• De-activating the digital input resets the drive.

-2…-6 = DI2(INV)…DI6(INV) – Denes an inverted digital input DI2…DI6 as a fault reset source.

• See DI1(INV) above.

OM 1190-1 • MD4 VFD 46 www.DaikinApplied.com

aCTual sIgnals and parameTers

Loading...

Loading...