Filtration, cleanliness level and β

x

-ratio (recommended minimum)

Cleanliness per ISO 4406

22/18/13

Efficiency β

x

(charge pressure filtration)

β

15-20

= 75 (β

10

≥ 10)

Efficiency β

x

(suction and return line filtration)

β

35-45

= 75 (β

10

≥ 2)

Recommended inlet screen mesh size

100 – 125 µm

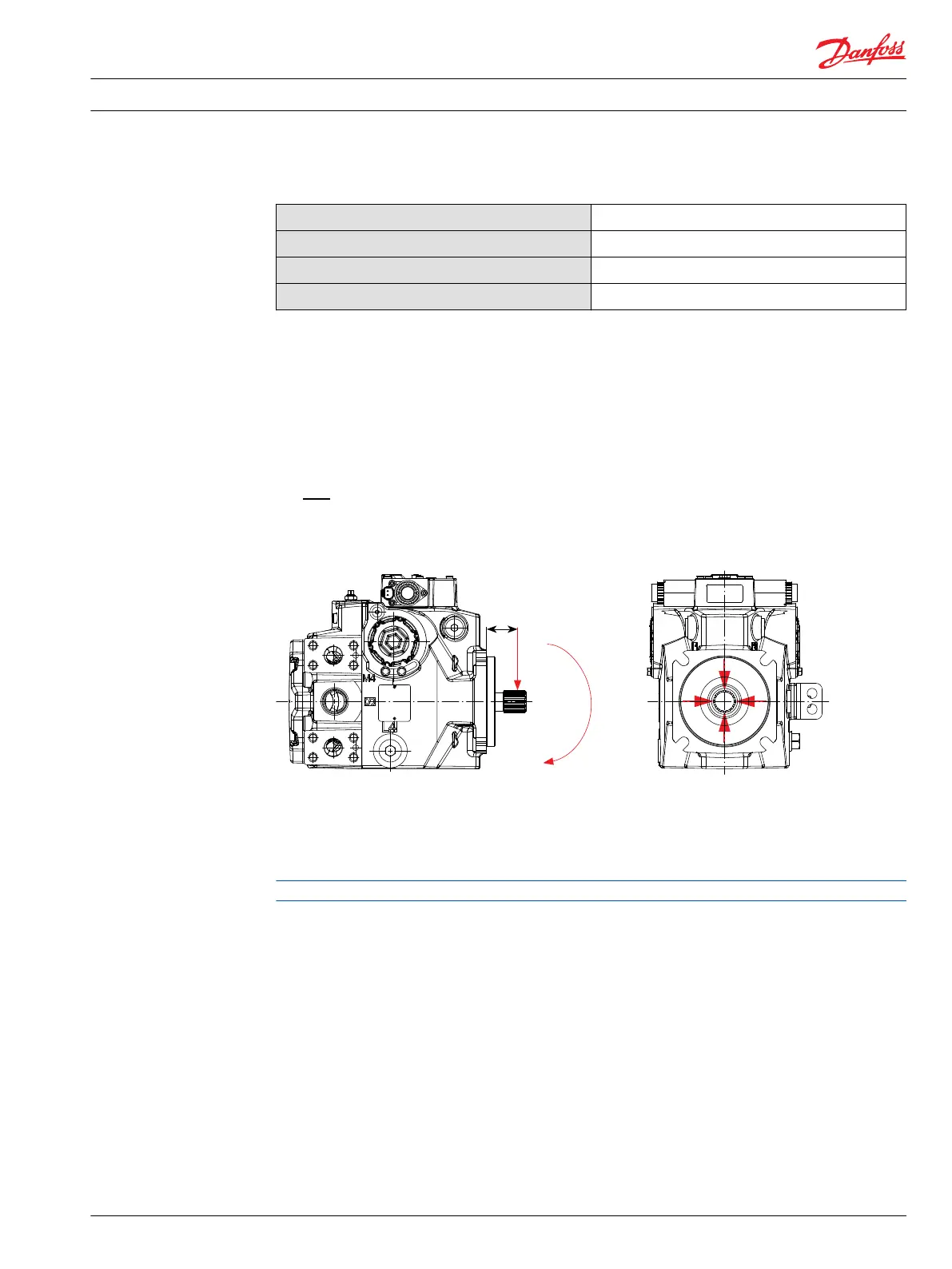

External radial shaft loads

The pumps are designed with bearings that can accept some external radial loads. The external radial

shaft load limits are a function of the load position and orientation, and the operating conditions of the

unit. External radial shaft loads impact lifetime. For lifetime calculations please contact Danfoss Power

Solutions representative.

The maximum allowable radial load (R

e

) is based on the maximum external moment (M

e

) and the

distance (L) from the mounting flange to the load. It may be determined using the following formula:

Radial load position

P003 318E

L

270° R

e

R

e

M

e

180° R

e

90° R

e

0° R

e

M

e

= shaft moment

L = flange distance

R

e

= external force to the shaft

Thrust loads should be avoided. Contact factory in the event thrust loads are anticipated.

Bearing life H1P 069/078

Maximum external shaft moment based on shaft deflection (both sizes 069/078):

M

e

= 109 N•m [965 lbf•in]

All external shaft loads affect bearing life. In applications with external shaft loads, minimize the impact

by positioning the load at 0° or 180° as shown in the figure. Danfoss recommends clamp-type couplings

for applications with radial shaft loads.

Contact your Danfoss representative for an evaluation of unit bearing life if you have continuously

applied external loads exceeding 25 % of the maximum allowable radial load (R

e

) or the pump

swashplate is positioned on one side of center all or most of the time.

Mounting flange loads H1P 069/078

The moments shown below apply for top or side control orientation.

Technical Information

H1 Axial Piston Single Pumps, Size 069/078

Technical specifications

11062169 • Rev 0700 • November 2015 7

Loading...

Loading...