4.2 Load and Motor

4.2.1 Configuration

Selection of configuration and torque characteristics has an

effect on which parameters can be seen in the display. If

[0] Open loop is selected, all parameters relating to PID

regulation is filtered out. This means that the user only

sees the parameters that are relevant for a given

application.

100 Configuration

Value:

Speed control, open loop

(SPEED OPEN LOOP) [0]

Speed control, closed loop

(SPEED CLOSED LOOP) [1]

Process control, closed loop

(PROCESS CLOSED LOOP) [3]

Function:

This parameter is used to select the configuration to which

the frequency converter is to be adapted. This makes

adaptation to a given application simple, since the

parameters not used in a given configuration are hidden

(not active).

Description of choice:

If [0] Speed control, open loop is selected, normal speed

control is obtained (without feedback signal) with

automatic load and slip compensation to ensure a

constant speed at varying loads. Compensations are active,

but may be disabled in parameter 134 Load compensation

and parameter 136 Slip compensation as required.

If [1] Speed control, closed loop is selected, better speed

accuracy is obtained. Add feedback signal, and set the PID

regulator in parameter group 400 Special functions.

If [3] Process control, closed loop is selected, the internal

process regulator is activated to enable precise control of a

process in relation to a given process signal. The process

signal can be set to the relevant process unit or as a

percentage. Add feedback signal from the process and set

the process regulator in parameter group 400 Special

functions. Process closed loop is not active if a DeviceNet

card is mounted and Instance 20/70 or 21/71 is selected in

parameter 904 Instance types.

101

Torque characteristic

Value:

Constant torque

(Constant torque) [1]

Variable torque low

(torque: low) [2]

Variable torque medium

(torque: med) [3]

Variable torque high

(torque: high) [4]

Variable torque low with CT start

(VT LOW CT START) [5]

Variable torque medium with CT start

(VT MED CT START) [6]

Variable torque high with CT start

(VT HIGH CT START) [7]

Special motor mode

(Special motor mode) [8]

CT = Constant torque

Function:

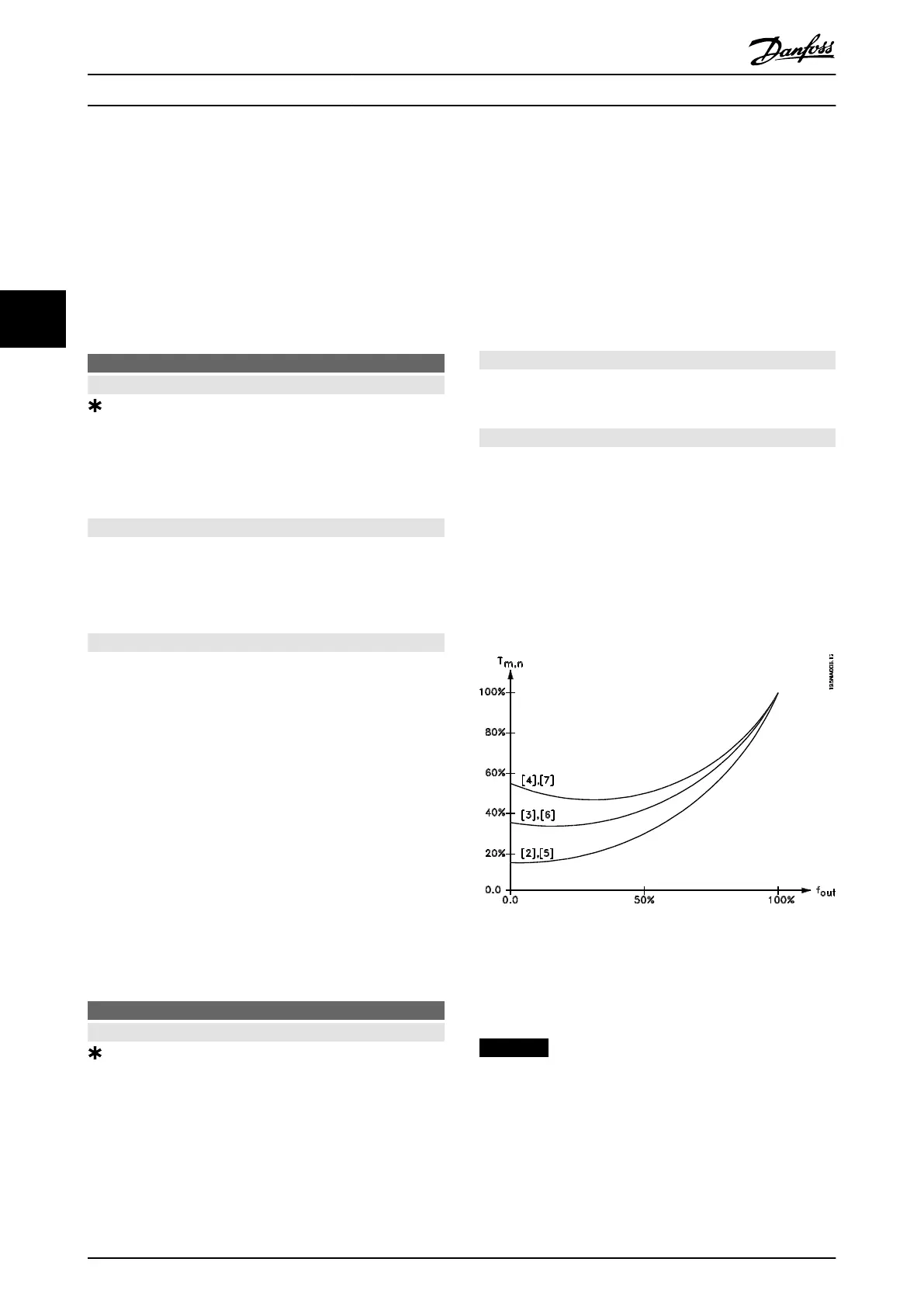

Use this parameter to adapt the U/f ratio of the frequency

converter to the torque characteristic of the load. See

parameter 135 U/f ratio.

Description of choice:

If [1] Constant torque is selected, a load-dependent U/f

characteristic is obtained, in which output voltage and

output frequency are increased at increasing loads to

maintain constant magnetisation of the motor.

Select [2] Variable torque low , [3] Variable torque medium or

[4] Variable torque high, if the load is square (centrifugal

pumps, fans).

Select [5] Variable torque - low with CT start , [6] Variable

torque - medium with CT start or [7] Variable torque - high

with CT start if a greater breakaway torque is needed than

can be achieved with the 3 first characteristics.

Illustration 4.2 Torque Characteristics

Select [8] Special motor mode if a special U/f setting is

needed that is to be adapted to the present motor. The

break points are set in parameters 423-428 Voltage/

frequency.

NOTICE

Load and slip compensation are not active if variable

torque or special motor mode have been selected.

Programming Design Guide

68 Danfoss A/S © Rev. May/2014 All rights reserved. MG27E402

44

Loading...

Loading...