Chapter 3 Wiring ASDA-A2

3-74 Revision February, 2017

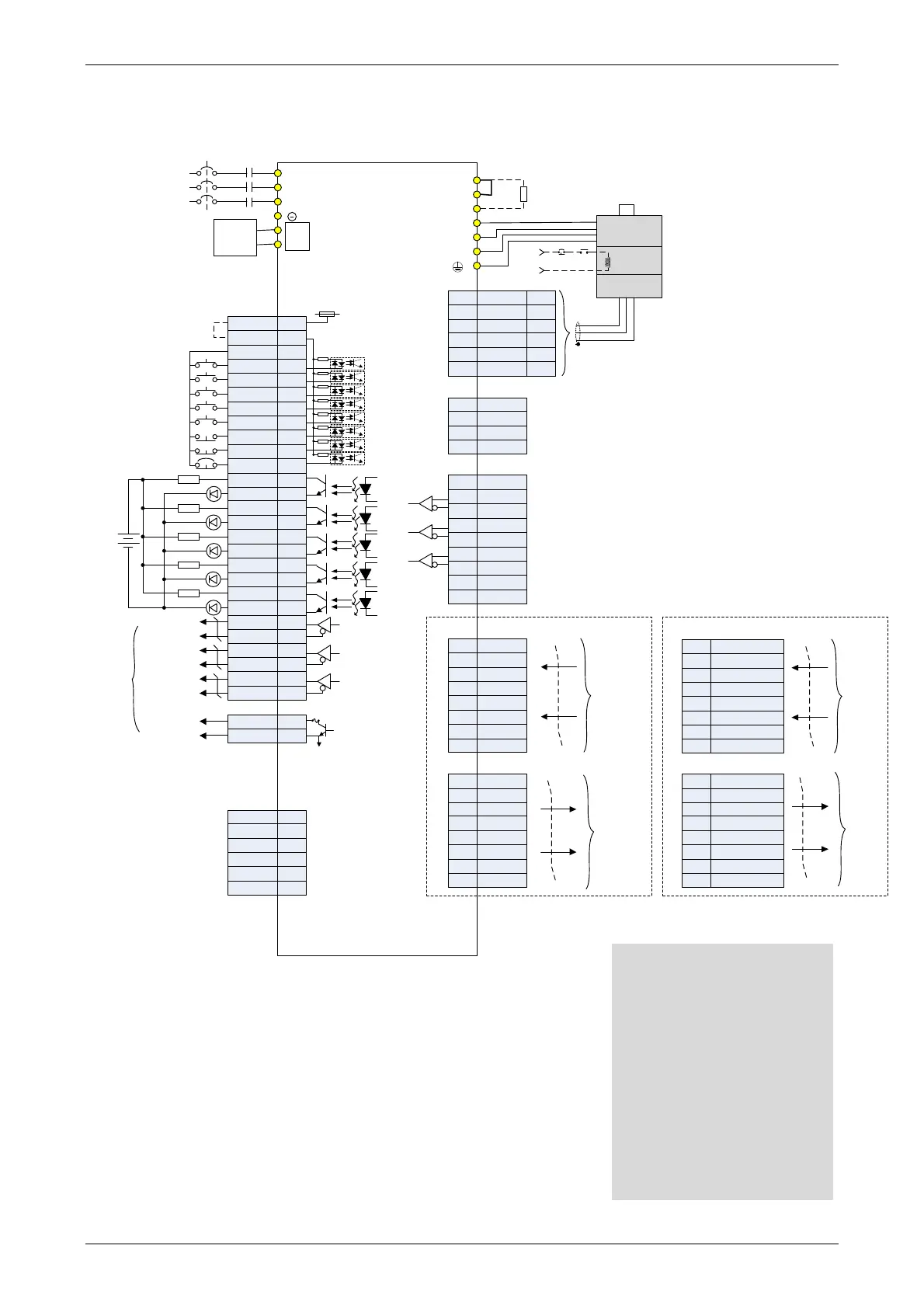

3.13.5 Communication Mode

VDD

COM+

COM-

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DO1+

DO2-

DO3-

DO4-

DO2+

DO3+

DO4+

DO5+

DO1-

DO5-

45,47,49

17

11

9

10

34

8

33

32

30

7

6

5

4

3

1

2

26

28

31

27

T+

T-

-

+5V

-

GND

4

7

13,15

14,16

9

5

+5V DC

Data-

Data+

GND

4

3

1

2

Opt A

+5V

Opt B

Opt /B

Opt /A

Opt Z

Opt /Z

GND

GND

9

7

5

6

3

1

2

8

4

CN2

CN4

CN1

CN5

Blue

Blue/

Black

P⊕

D

C

U

V

W

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

R

S

T

24V

0V

MC

MCCB

AC 380/480 V

3-phase

Servo Drive

ASDA-A2 series

Reserved

ORGP

NL

PL

EMGS

1.5KΩ

1.5KΩ

1.5KΩ

1.5KΩ

1.5KΩ

SRDY

ZSPD

TPOS

HOME

ALRM

24V

DC 24V

Regenerative

resistor

Red

White

Black

Green

SG

Brake

Power supply

Encoder

BRKREMGS

24V

Twisted-pair or

twisted-shield

cable

DC 24V

Power

Supply

Reserved

Reserved

Reserved

*1

*2

*4

*3

Red/Red&

White

Black/

Black&White

-

-

21

22

24

50

25

23

Max. output current 3A

Voltage 50V

CN3

CN6 DMCNET (

for ASDA-A2-F)

9

11

10

12

13

14

15

16

Data output

DMCNET_1A

-

-

-

-

DMCNET_1B

DMCNET_2A

DMCNET_2B

1

3

2

4

5

6

7

8

Data input

DMCNET_1A

-

-

-

-

DMCNET_1B

DMCNET_2A

DMCNET_2B

9

11

10

12

13

14

15

16

CAN H

CAN L

CAN GND

-

-

-

CAN GND

-

CN6 CANopen (

for ASDA-A2-M)

1

3

2

4

5

6

7

8

CAN H

CAN L

CAN GND

-

-

-

CAN GND

-

Data input

Data output

OCZ

GND

48

13

/OA

OA

OB

/OB

/OZ

OZ

A phase

differential signal

B phase

differential signal

Z phase

differential signal

Z phase signal

(open-collector)

Encoder

pulse

output

RS485+

RS232_RX

RS232_TX

GND

RS485-

-

5

6

4

3

1

2

Please note:

*1 Please refer to C9 ~ C12 wiring

diagrams (SINK / SOURCE

mode) in section 3.4.4.

*2 4.5kW and below drives provide

built-in regenerative resistor.

*3 The coil of brake has no

polarity.

*4 For USB connection. It is used

to connect to personal

computer or notebook.

*5 A2-F only supports DMCNET

mode.