ASDA-A2 Chapter 3 Wiring

Revision February, 2017 3-3

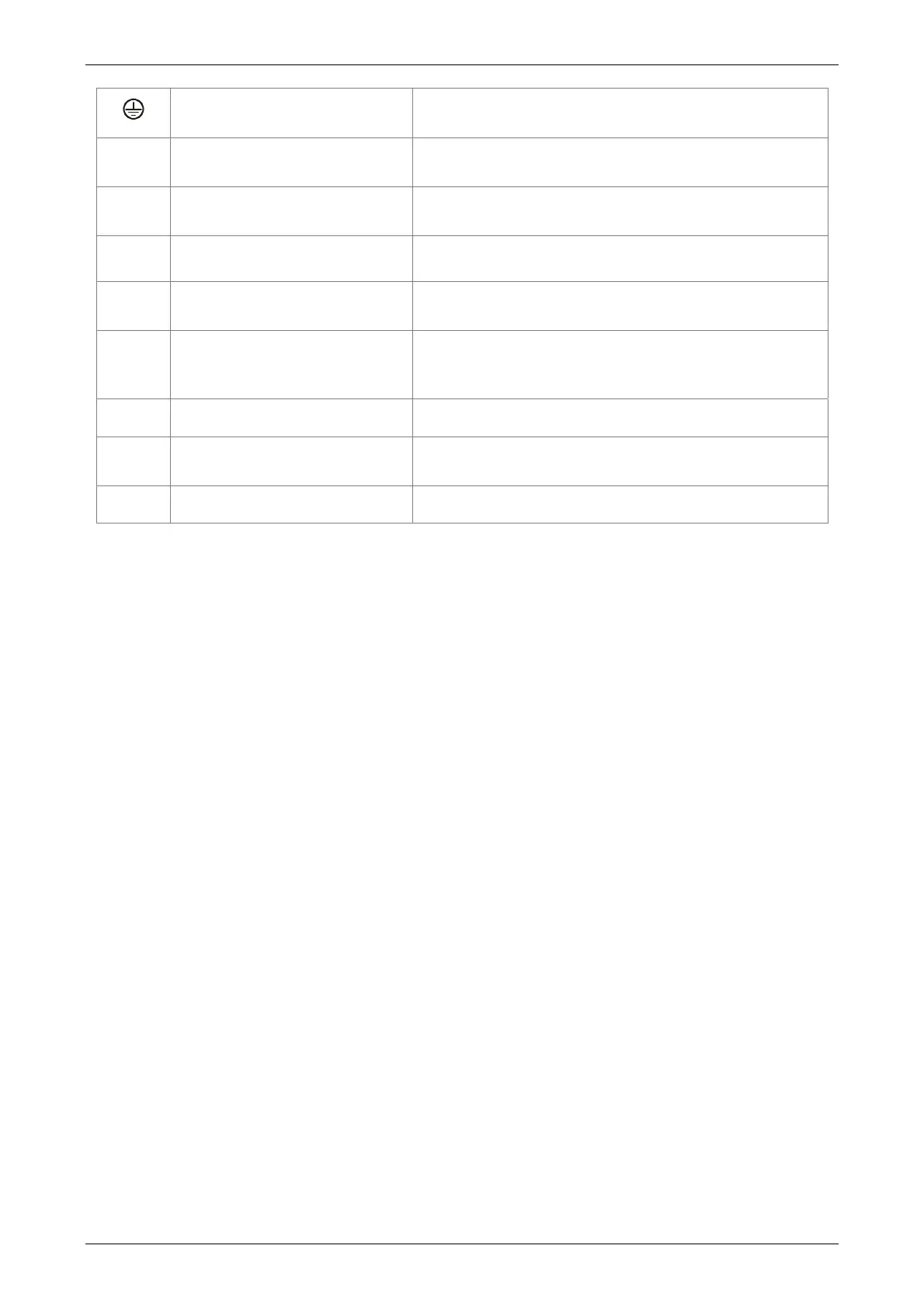

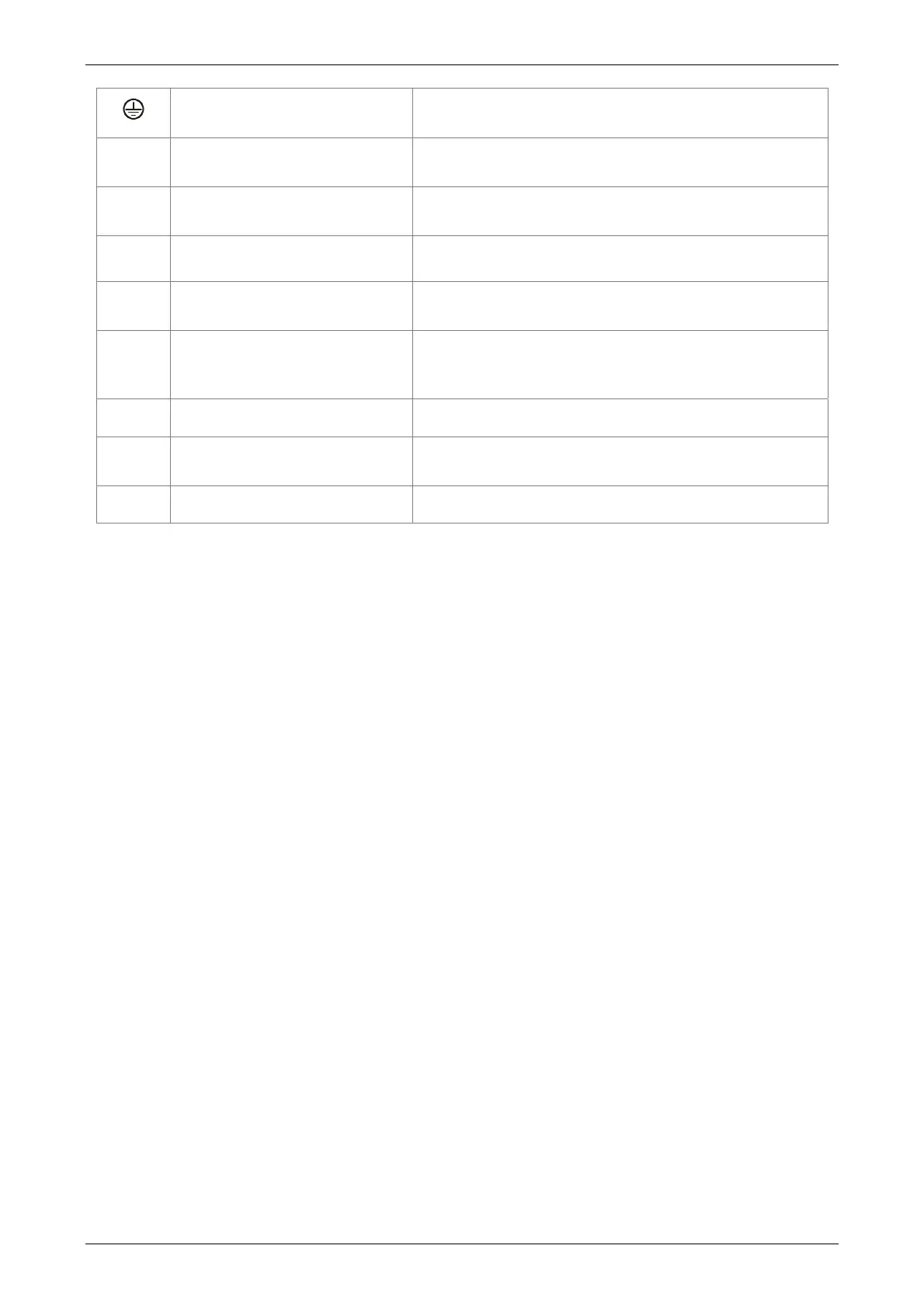

Ground terminal

Connect to the ground wire of power and servo

motor.

CN1

I/O connector (Option)

Connect to the host controller. Please refer to

section 3.4.

CN2

Connector (Option)

Connect encoder of the motor. Please refer to

section 3.5.

CN3

Connector Option)

Connect to RS-485 or RS-232. Please refer to

section 3.6.

CN4

USB connector (Type B)

(Option)

Connect to personal computer (PC or notebook).

Please refer to section 3.7.

CN5

Connector (Option)

Connect to linear scale or encoder for full-closed

loop and motor feedback. Please refer to section

3.8.

CN6

CANopen connector (Option) RJ45 connector. Please refer to section 3.9.

CN7

Extension digital input

connector (Option)

Extension DI connector. Please refer to section

3.10.

CN8

Battery connector Connector for absolute type of battery box

Pay special attention to the followings when wiring:

1. When the power is cutoff, do not touch R, S, T and U, V, W since the capacitance inside the

servo drive still contains huge amount of electric charge. Wait until the charging light is off.

2. Separate R, S, T and U, V, W from the other wires. The interval should be at least 30 cm

(11.8 inches).

3. If the wire of encoder CN2 or CN5 connecter is not long enough, please use shielded twisted-

pair cable which cannot exceed 20 meters (65.62 inches). If it exceeds 20 meters, please

choose the bigger wire diameter of signal cable to ensure it will not cause signal fading. As

for the encoder wiring specification of 20-meter-long cable, please use AWG26 of wire size

and metal braided shield twisted-pair cable which complies with the standard of UL 2464.

4. When using CANopen, please use the standard shielded twisted-pair cables to ensure the

communication quality.

5. When selecting the wire rod, please refer to Section 3.1.6.

6. Do not install the plug-in capacitance in servo drive. It might burn out the soft-start resistance

and danger will occur.

Loading...

Loading...