1-2

11C-M12M0-0004-0

1. OUTLINE OF EACH MECHANISM AND ADJUSTMENTS

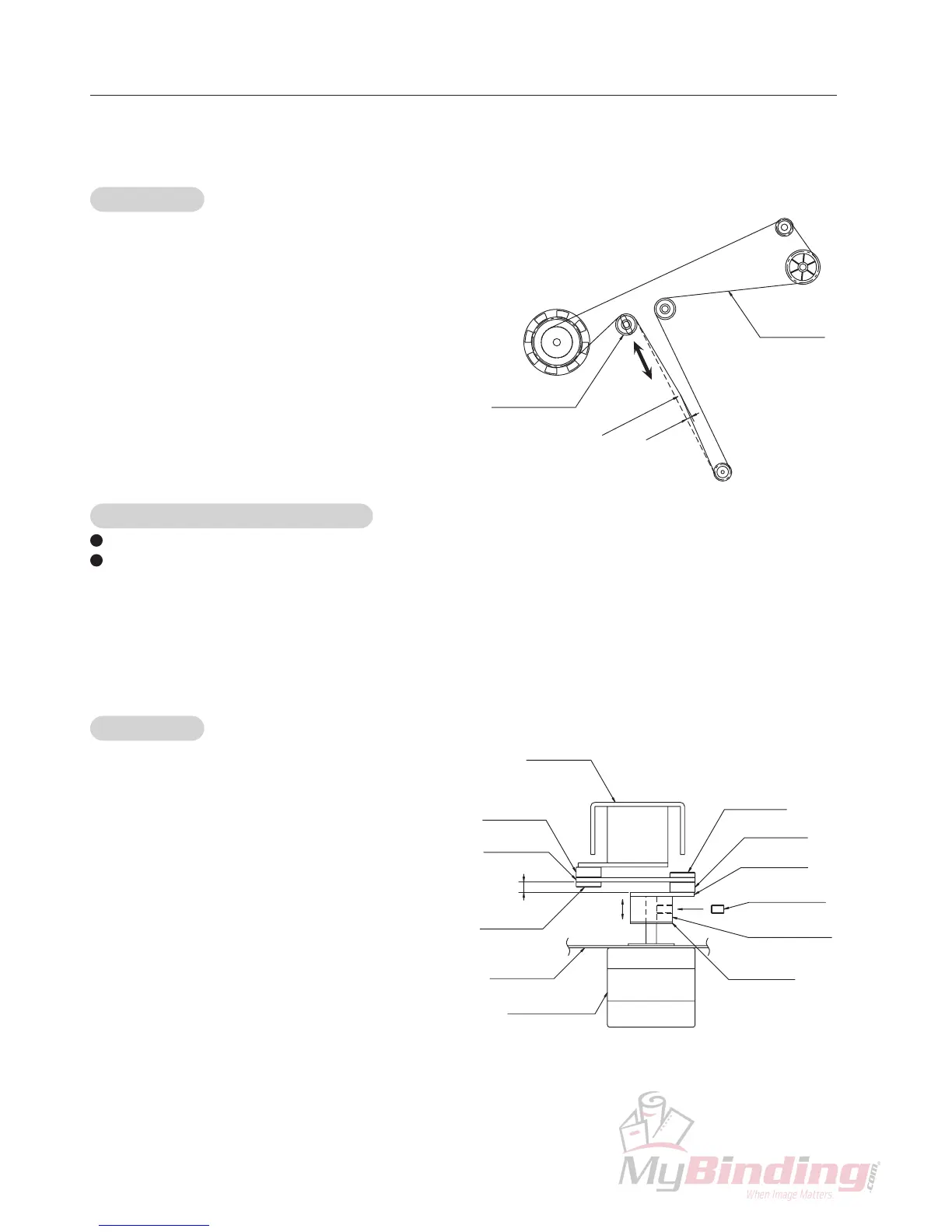

Adjustments

(1) Adjusting the tension of the timing belt

Adjust the position of the pinch roller unit so that the

belt slacks by 10 mm when a pressure of 1.96 N

(200 gf) is applied.

Timing belt

014-10243

Pinch roller unit

96F-1125X

1.96 N (200 gf)

10 mm

Precautions on replacing the flat belt

Replace taking note of the rotating direction of the flat belt. (Arrow at the back of the flat belt)

Replace the flat belt in pairs.

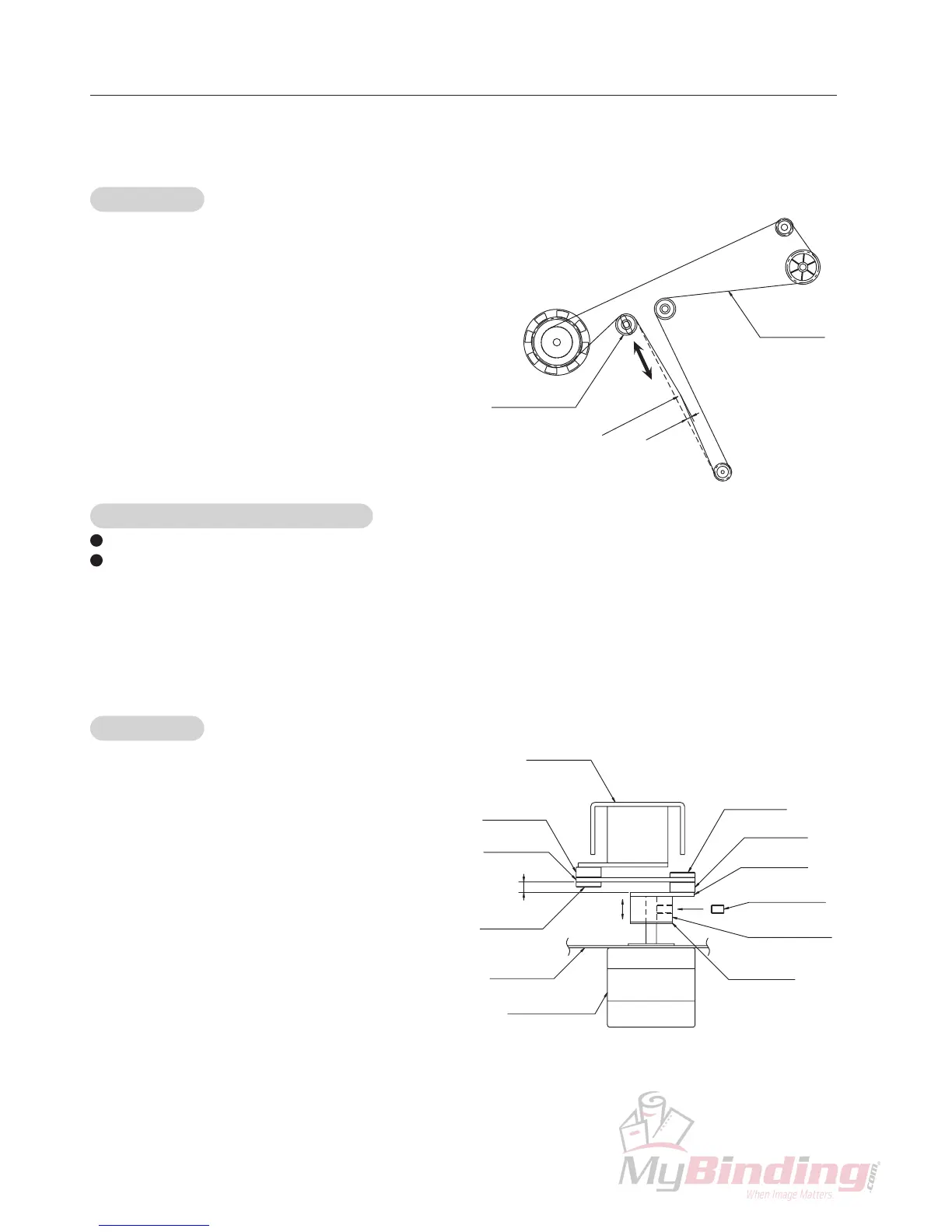

1-2. Back Jogger Mechanism

The base moves forward and backward by changing the rotating movements of the stepping motor to linear

movements.

The pusher attached to the base pushes in the paper.

Adjustments

(1) Adjusting the position of the collar 05-20-12

Adjust the position of the collar 05-20-12 so that the

lever and link become parallel.

1-1. Conveyance Mechanism (Entrance)

Paper is conveyed by the flat belt.

0Z4-08022

11C-1332X

11C-1310X

0Z4-08022

11C-1324X

Unbrako4 × 6

0X4-12050

Stepping motor

99A-8013X

Link

98H-1322X

Lever

Plate

11C-1334X

Z

Collar 05-20-12

11C-1333X

Parallel

X

Bracket

X

0X4-12050

Z

Base plate

Loading...

Loading...