Section 6: Control features

Calendar/clock

Integral to several functions of the control is an internal

calendar/clock. The digital clock maintains the year, month,

day, hour, minute and seconds, within 1 second. The

display format is user-selectable (see FC 142 and FC 143).

The control time is synchronized to the system frequency

when powered by ac. When ac power is lost, the clock

maintains time, for a minimum of 72 hours, by using a

crystal oscillator and a capacitor as the power source.

Twenty minutes on ac power is required to fully charge the

capacitor.

The LCD displays the current date and time at the end of the

self-test when the front panel is turned on. However, upon

power-up after extended loss of power, the control clock time

and date will default to midnight, January 1, 1970.

The date and time can be read and set at FC 50. When

setting, all of the digits must be entered using the standard

24-hour format (MM/DD/YYYY hh:mm). If an error is made

while entering the values, backspace using either arrow

scroll key.

Daylight Savings Time is available starting with the CL-6B

control. The factory default is for daylight savings time to be

off. Daylight savings time can be turned on using FC 151.

Metering

The control has extensive metering capabilities, which

are categorized as Instantaneous, Forward Demand, and

Reverse Demand.

Instantaneous metering

Instantaneous metering values are refreshed once each

second. They may be accessed directly at FC 6 through

FC 19, FC 125, and FC 126. See Table 5-3 in the Control

Programming section of this manual for more information

on these function codes.

Demand metering

The control provides demand metering values for these

parameters: load voltage, and, for forward and reverse,

source voltage, compensated voltage, load current, kVA

load, kW load, and kvar load. For each of these parameters

the present value, the high value since last reset, and

the low value since last reset are recorded, as well as

the earliest time and date that the high and low values

occurred.

Additionally, the power factor at kVA-high demand and

kVA-low demand are recorded. All of these values are

stored in non-volatile memory separately for forward and

reverse power conditions.

See Table 5-3 in the Control Programming section

of this manual for information on the function codes

associated with demand metering (FC 20 through FC 38, FC

127, and FC 128).

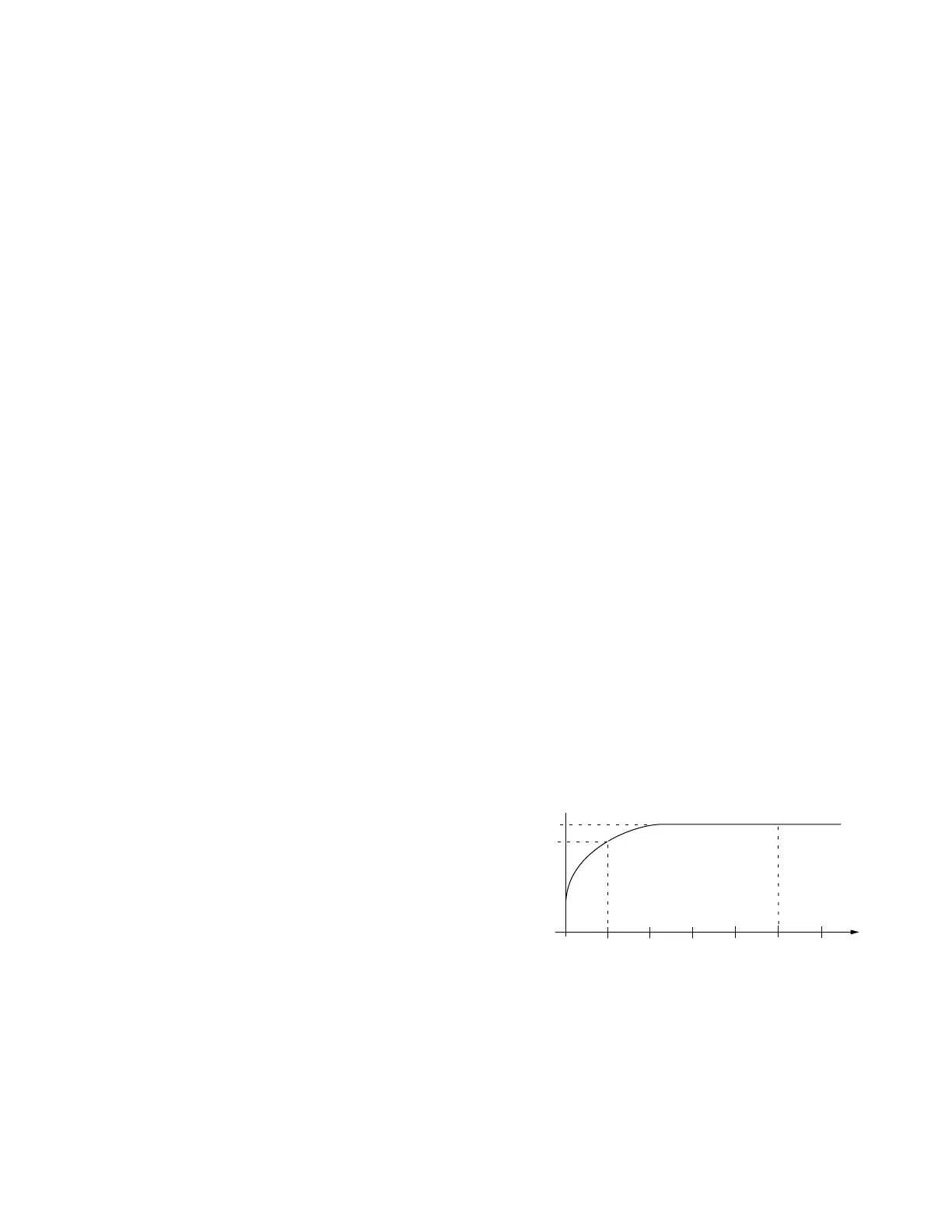

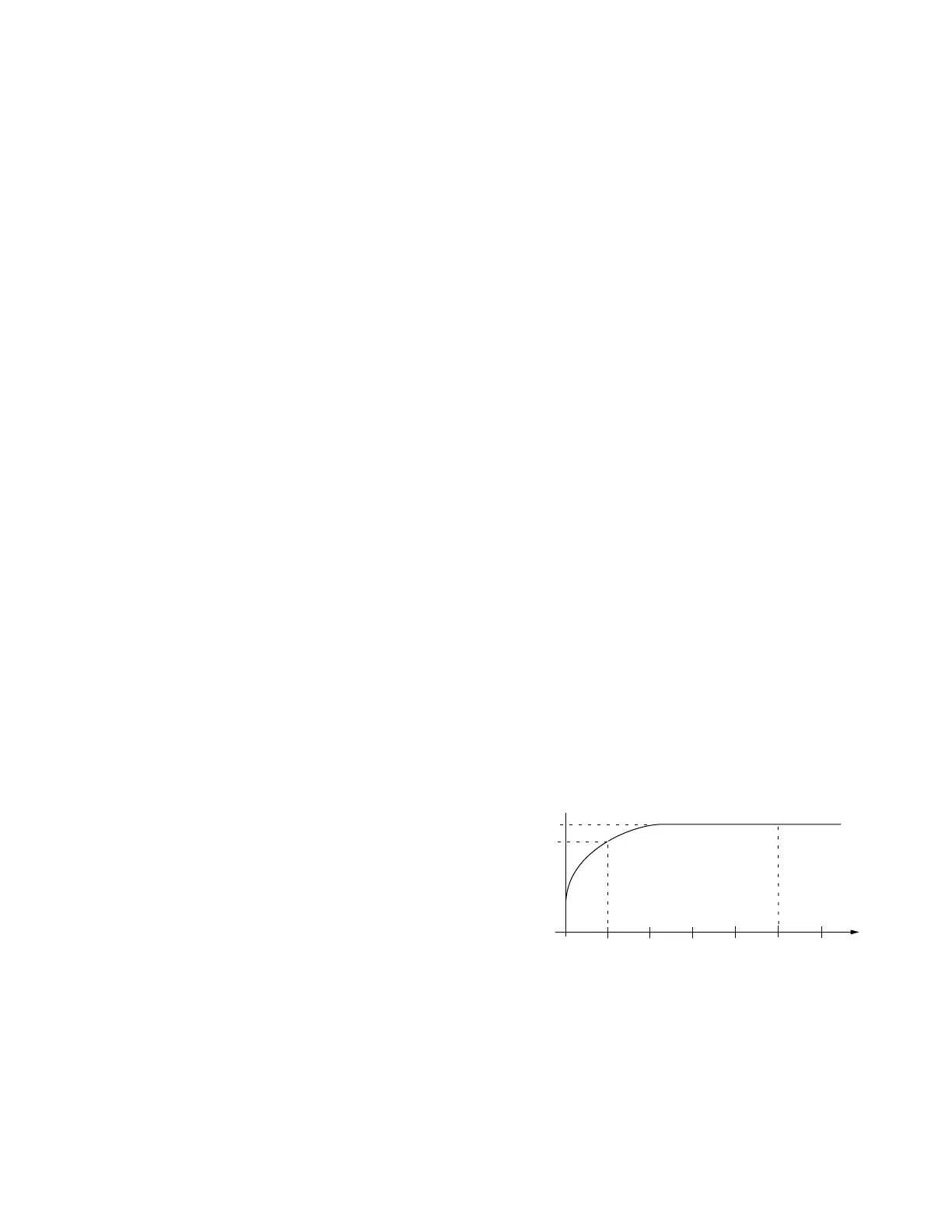

Demand task operation

The demand metering function is based upon a sliding

window concept, or moving integral. The algorithm

implemented simulates the response of a thermal demand

meter which will reach 90% of its final value after one

demand interval in response to a step function input. See

Figure 6.1.

The task works like this:

1. For 3 minutes after a power outage or power reversal,

no demands are calculated. This allows the utility

system to stabilize from the event which created the

outage or power reversal.

2. At 3 minutes, the present demands (for the appropriate

power direction) are set to their corresponding

instantaneous value and the integration algorithm

begins according to the programmed demand interval at

FC 46.

3. At 15 minutes or at the demand time interval (whichever

is longer), the high/low demand values begin to track the

present demand, similar to drag hands. All demand

values are calculated continuously and, if a change

has occurred, the high/low demands are stored in the

non-volatile memory every 15 minutes. This prevents

loss of data during a power interruption or outage.

Notice that the provisions are made to reset any demand

value by itself via the change/reset key, or all demand

values can be reset simultaneously by entering FC 38. High

and low values will be set to their corresponding present

demand value, and the dates and times will be set to the

present date/time.

Two conditions can cause the present demands to be

invalid: The power has just been applied (within the

3-minute freeze period) or the power flow has changed

direction. If the control is metering in the forward direction,

the reverse present demands will be invalid; if metering in

the reverse direction, the forward present demands will be

invalid.

Figure 6-1. Demand time interval response.

100%

90%

6T

0

1T

2T

3T

4T

5T

Demand Time Interval

t

77

CL-6 SERIES CONTROL INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS MN225016EN January 2016

Loading...

Loading...