Auto-restore local (ARL)

Two additional functions that can be enabled at FC 450 are

Auto-Restore Local Heartbeat (ARLH) and Auto-Restore

Local Comms (ARLC). When SCADA communications are

being used to modify basic configuration settings, enabling

Auto-Restore Local will allow the control to revert control

settings modified through SCADA communications back

to the original settings programmed into the control. With

ARLH, the settings will revert when a heartbeat signal is

lost or discontinued. For ARLC, the settings will revert

when a communications signal is lost. The settings that are

affected by ARL are the same as those listed for Alternate

Configurations. When either ARL function is active, FC 451

will display Active.

For more information on setting up ARL with SCADA

communications, contact your Eaton representative.

Programmable input/output (P.I.O.)

Alternate Configurations settings can be enabled using P.I.O.

In order to enable Alternate configuration settings using

P.I.O., the Alternate Configuration setting (FC 450) must be

set to P.I.O. Equations must then be created using CCI soft-

ware which program the conditions under which Alternate

Configuration settings will become active. When Alternate

Configuration settings are active due to P.I.O. logic, the

status at FC 451 will display Active.

For more information on enabling Alternate Configuration

settings using P.I.O., contact your Eaton representative.

Transducer connections

Refer to Figure 10-4. To monitor the load voltage (forward

direction), a transducer, nominal 120 Vac input, may be

connected as follows: Connect the transducer hot lead

to terminal V

4

on TB

1

and its ground lead to G on TB

1

. A

current transducer, 200 mA input, may be connected as

follows: Close knife switch C; remove the jumper between

C

2

and C

4

on TB

1

; connect the transducer hot lead to C

2

and its ground lead to C

4

; and open knife switch C.

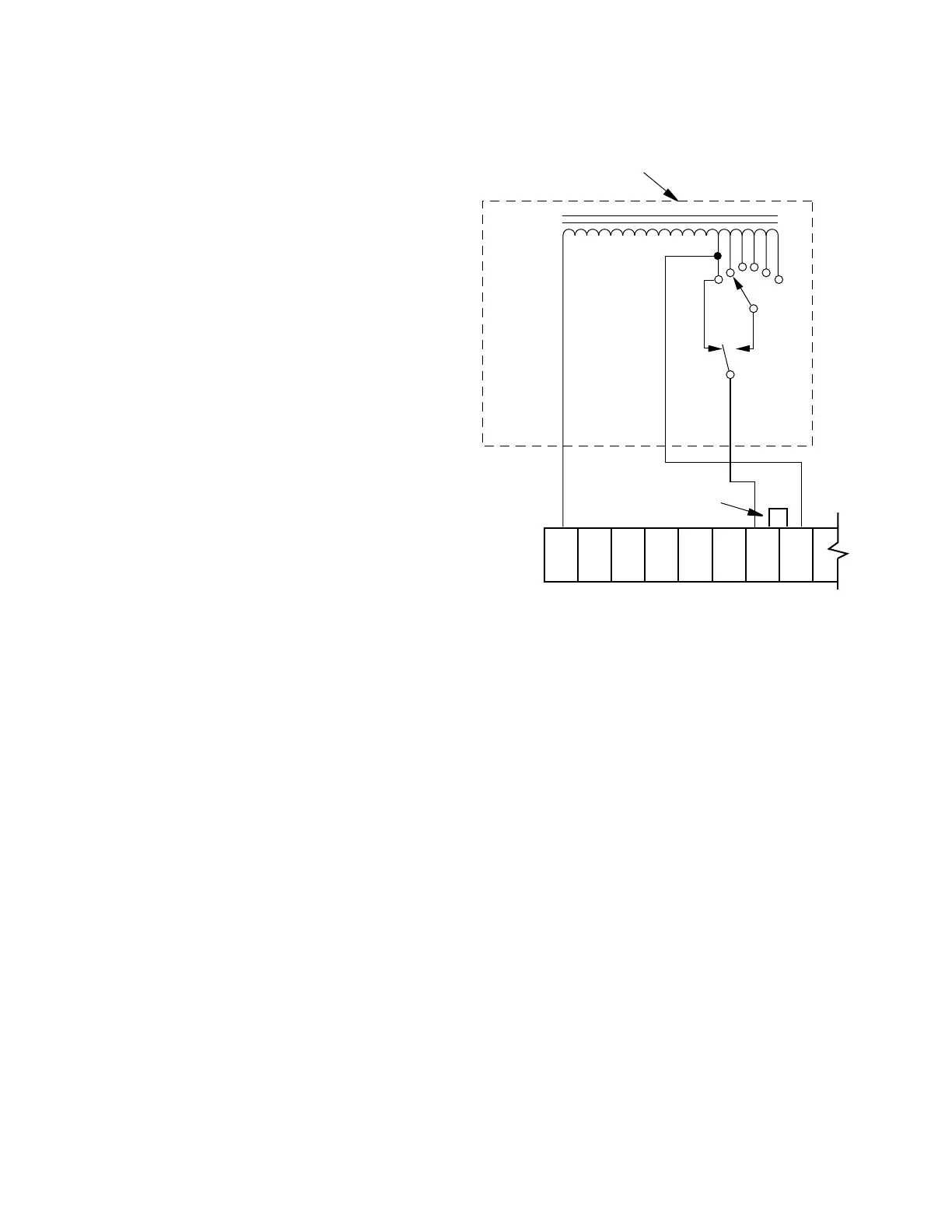

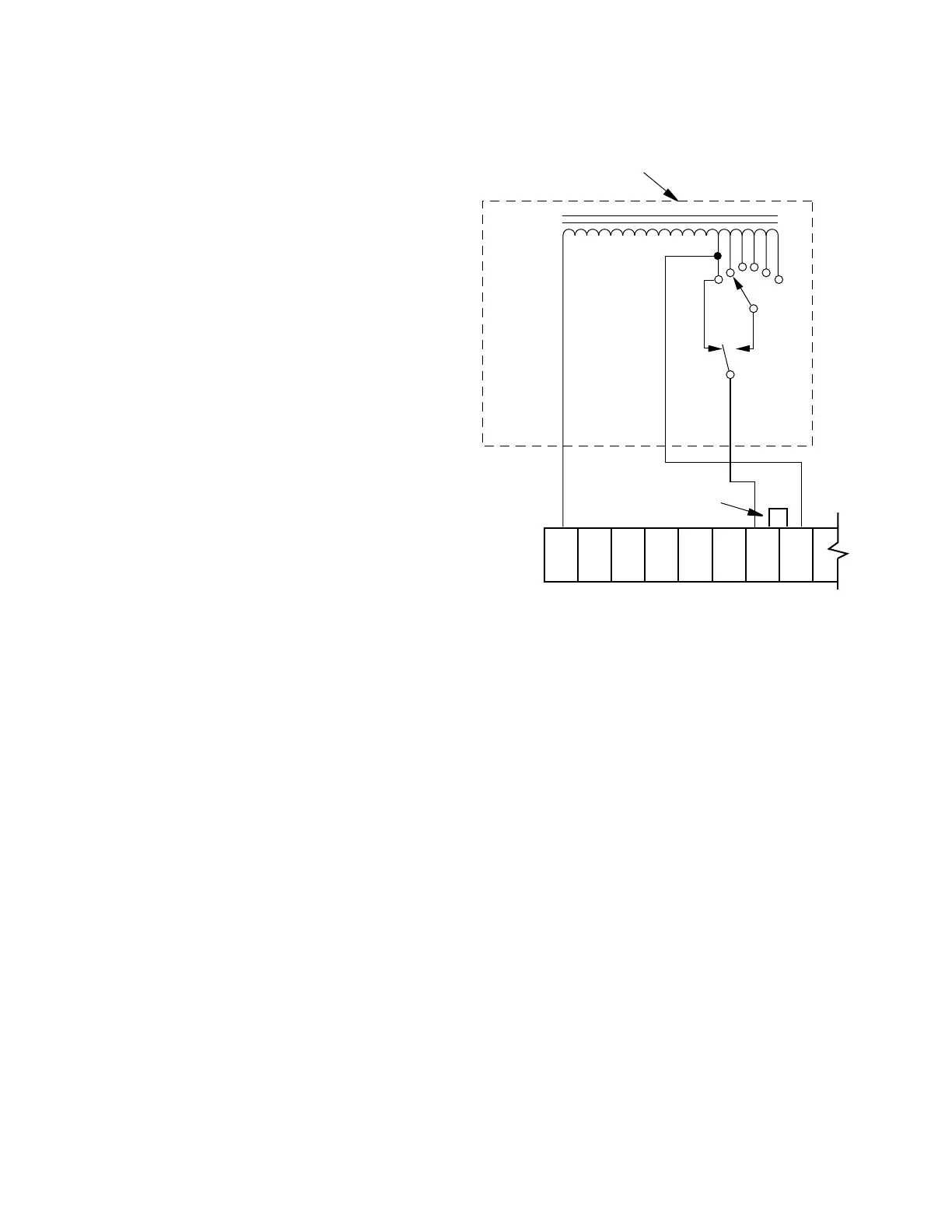

Fooler voltage scheme

Using this method, the voltage sensed by the control is

raised, thereby “fooling” the control into reducing the

voltage during its normal automatic operation. This method

can be used with the CL-6 Series controls. A VR module,

as shown in Figure 6-16, is usually supplied by the Remote

Terminal Unit (RTU) manufacturer. The VR module is usually

a tapped auto-transformer with a pulse-activated indexing

relay. When connected to the control back panel as shown,

the voltage sensed by the control is raised as the module is

pulsed to higher taps.

Since this method keeps the control in automatic operation,

Auto-Inhibiting is not used. An advantage of this method is

that it can be applied to many different models of controls

from many manufacturers. A disadvantage of this method

is that while VR is activated, the measured load voltage

is incorrect, as are all other calculated metering values

which use the load voltage. To avoid the effects of metering

inaccuracy, the Pulse Mode of VR should be used.

Figure 6-16. Typical user provided “Fooler

Voltage” module.

Common V(IN) V(OUT)

Relay

K

TB

1

G HS R

1

L

1

NL DHR V

S

V

5

Remove Jumper

User-provided Remote

Voltage Reduction Module

88

CL-6 SERIES CONTROL INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS MN225016EN January 2016

Loading...

Loading...