© Edwards Limited 2013. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

B722-40-880 Issue F

3.3.1 Inlet screen (supplied fitted)

Remove the inlet screen only if there is no possibility that debris can fall into the pump. If the inlet screen is removed,

the pumping speed will increase by up to 10%. Since the inlet screen protects the pump from contamination, do not

remove the inlet screen until the pump is mounted on the system.

It is not possible to remove the inlet screen from a pump with an NW40 inlet flange (EXT75DX only).

To remove the inlet screen from a pump with an ISO or CF inlet flange, use a bent wire hook or small screwdriver to

carefully lever the inlet screen out from the inlet flange.

To replace an inlet screen, locate it as centrally as possible over the ISO or CF inlet flange and then, with fingers

applying equal pressure around the edge of the screen, push it firmly downwards. If they are not already in place,

the tangs must be snapped into the locating groove in the inlet flange using a suitable tool to press them into position.

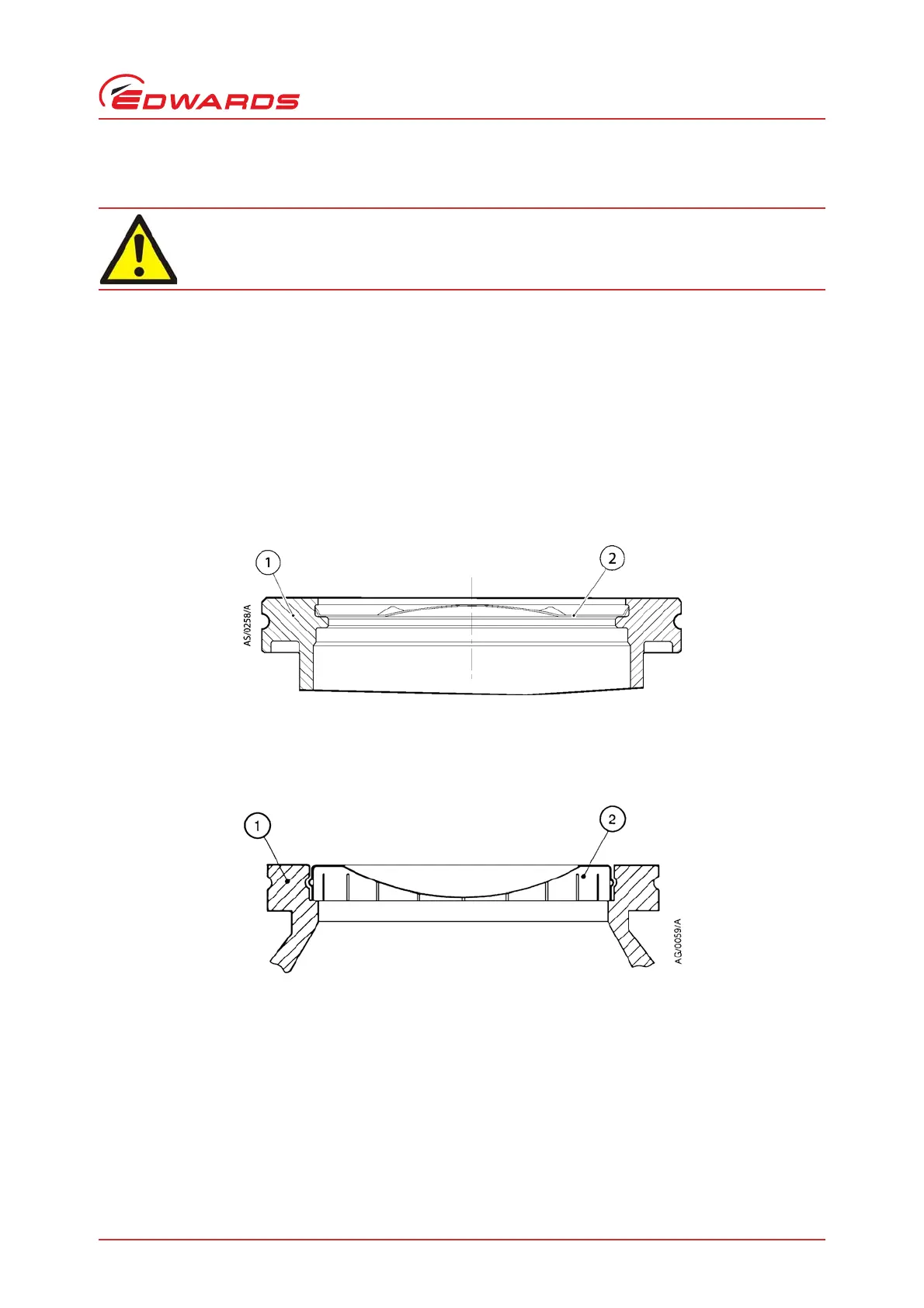

Figure 6 - Correct installation of the inlet screen (EXT75DX)

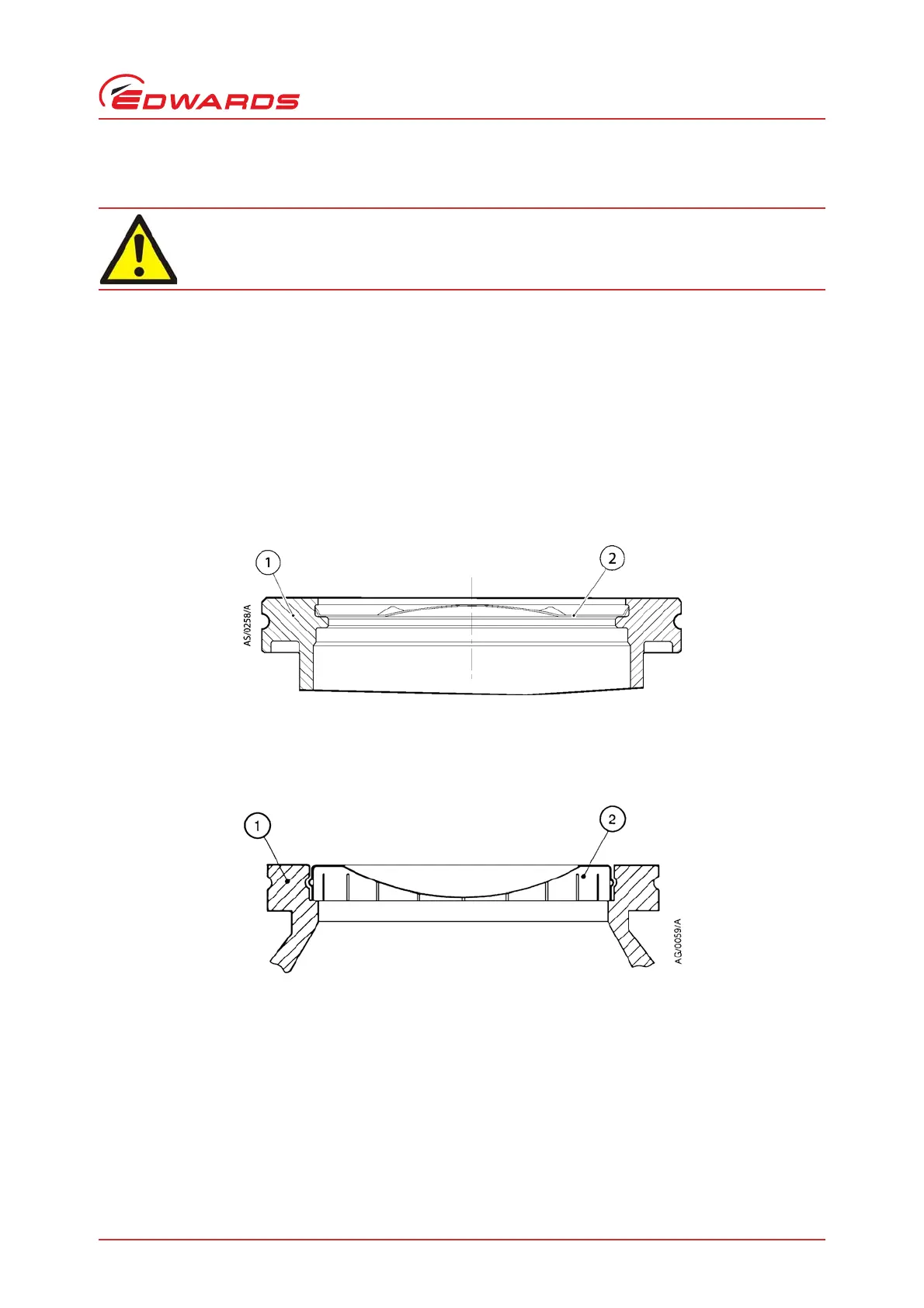

Figure 7 - Correct installation of the inlet screen (EXT255DX)

Removal of the inlet screen will expose the risk of injury from sharp edges.

1. EXT inlet flange 2. Inlet screen

1. EXT inlet flange 2. Inlet screen

Loading...

Loading...