B722-40-880 Issue F

Page 54 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

Any organic solvents can be used to clean the external surfaces of the pump. Edwards recommends using non-CFC

solvents, such as isopropanol or ethanol. Use a cleaning solution that is suitable for the contaminants on the pump

surfaces.

For environmental reasons, keep wastage of cleaning solutions and solvents to a minimum.

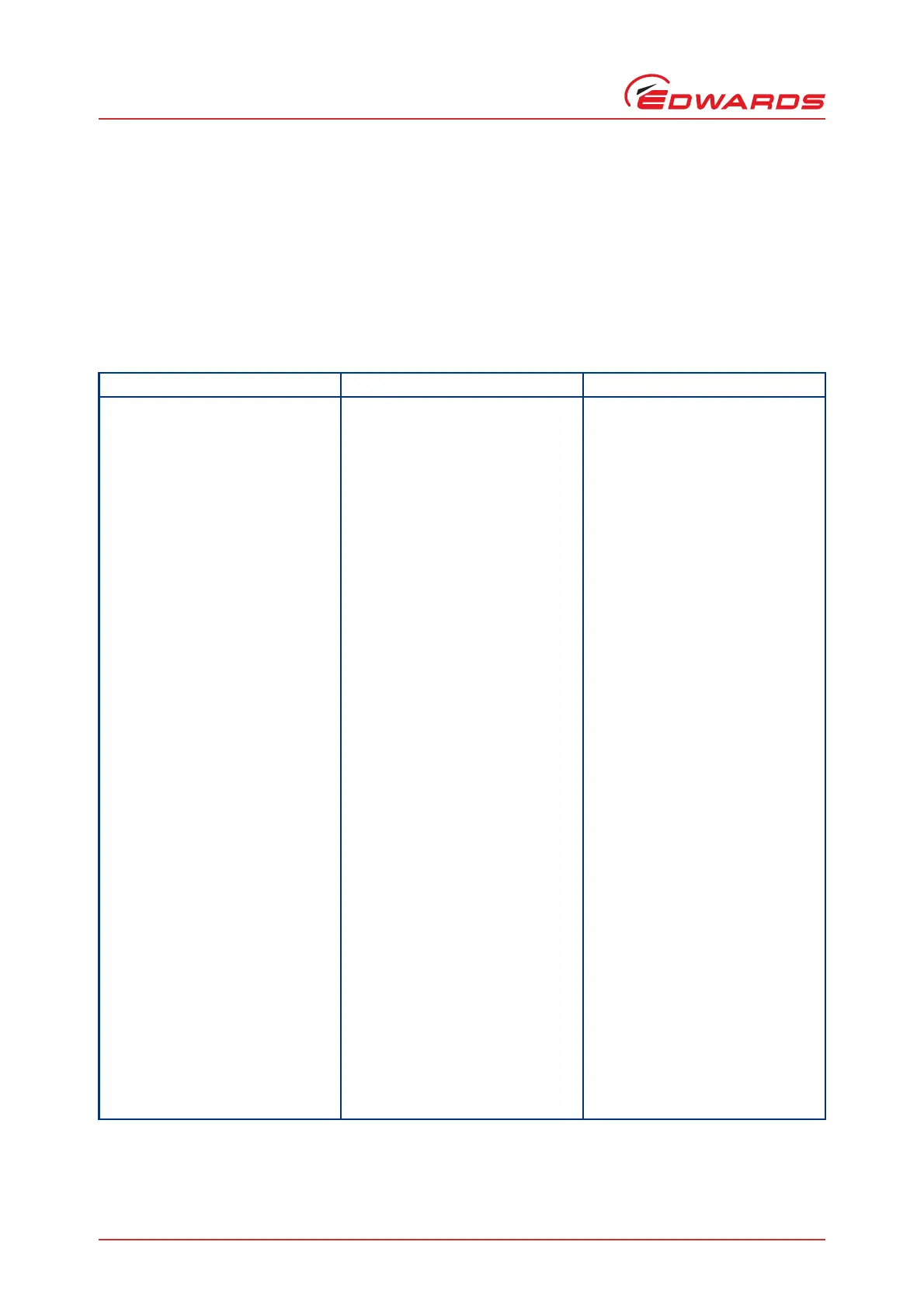

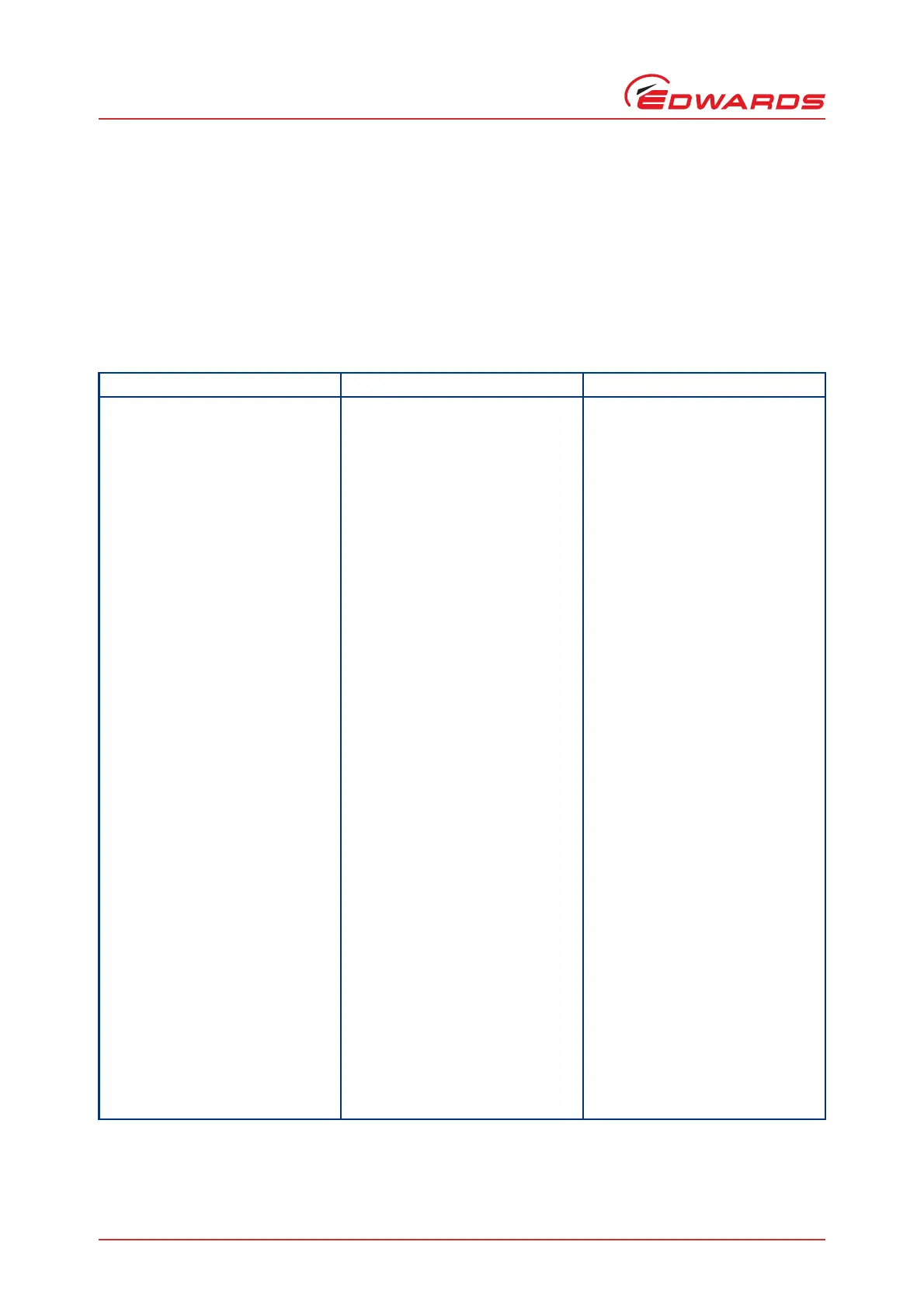

5.5 Fault finding

Refer to Table 23 for the possible causes of faults and the recommended actions to rectify faults.

Table 23 - Fault finding

Symptom Check Action

The Podule LEDs do not flash for 0.5

seconds when system switched on

Has the electrical supply failed? Ensure that the electrical supply is

switched on and the fuses (and

current limiting devices) have not

been tripped.

The pump does not rotate after a

parallel Start command is supplied

Check that the electricity supply is

on and whether the Fail output is

active

If there is a Fail signal, check

whether the orange status LED is

flashing. If it is, refer to

Section 5.5.1. If power is supplied,

there is no Fail signal and the rotor

still does not rotate then there is a

fault with the pump.

The pump does not rotate after a

serial Start command is sent

Check whether the pump returns a

reply to the Start command

If there is no reply, check that the

serial communications link is plugged

in and that Serial Enable is active

and that the electrical supply is on.

Check whether the orange status LED

is flashing. If it is, refer to 5.4.1.

The pump does not respond in multi-

drop mode

Check that the multi-drop is enabled Make sure the pump has a multi-drop

address and that commands are sent

using the multi-drop protocol.

The orange status LED flashes an

error code

Note the position of the long flashes

within the series of 6 flashes to work

out the error code.

Look up the flashing error code in

Section 5.5.1 and follow the advice

given.

The green Normal LED does not go on

or the pump is not rotating at full

speed or the pump fails whilst

running

Is the inlet pressure too high? If so reduce the pumping load or

check for a gross leak into the

system.

Is the pump running too hot? Increase the cooling to the pump.

Change from air cooling to water

cooling (refer to Section 2 for

maximum inlet pressure and cooling

requirements). Increase cooling-

water flow or decrease the water

temperature or do both. Check that

external heat sources (such as

system bakeout heaters) are not

excessive.

Does the rotor rotate freely? If not, the pump bearings may be

damaged. Contact the supplier or

Edwards.

Loading...

Loading...