Installation and commissioning

[19]

• Install measuring cables according to general standards for measuring and control

cables.

• If possible, install cables in metallic cable channels or tubes.

• Observe that the measuring cables are arranged orthogonally.

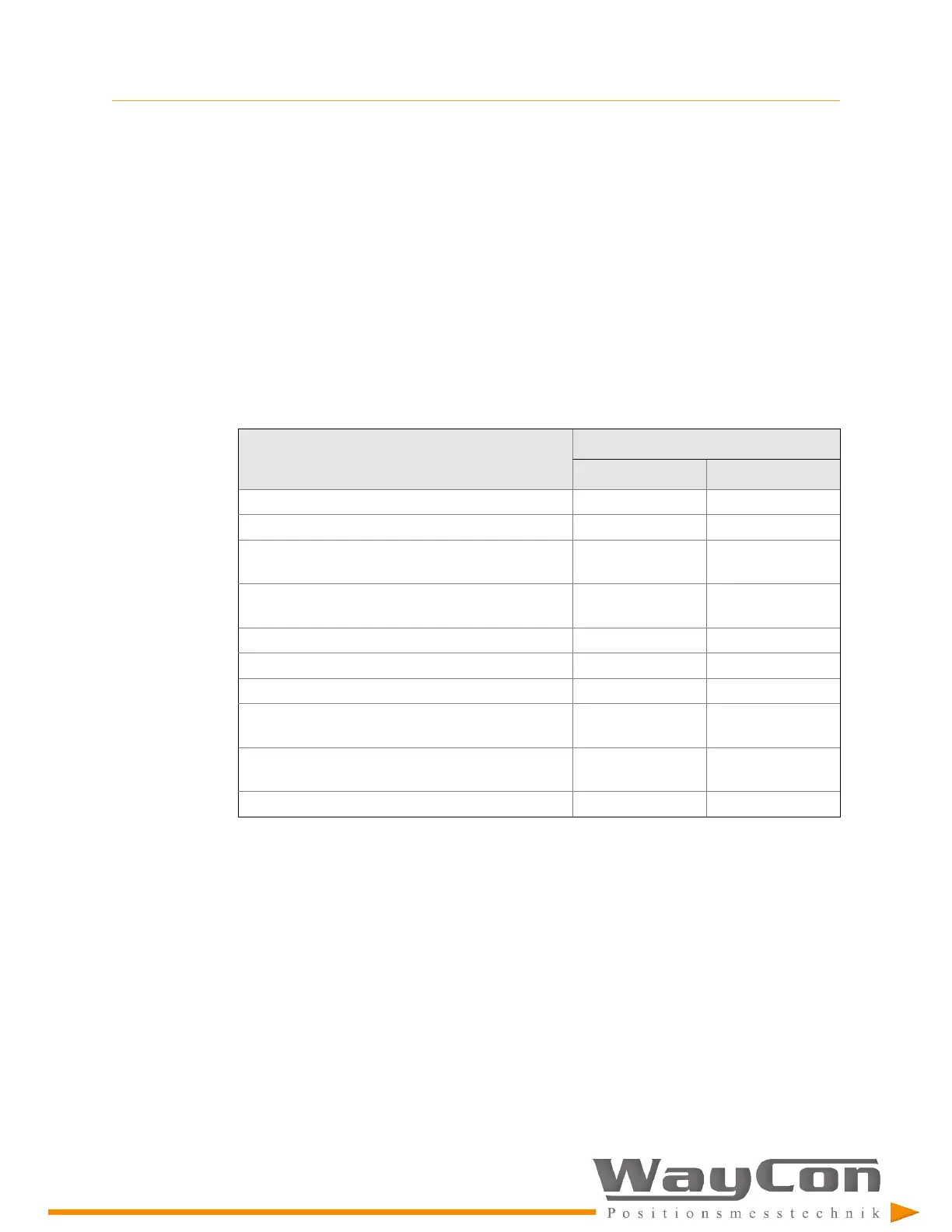

5.3.1 Connections and wiring

The EZ 1000 is equipped with four screw terminals for power supply connection and

output signal connection, and a LEMO socket for the connection of one eddy current

sensor. See

Table 5-1

for the minimum and maximum permissible wire cross-section of the

screw terminals.

Table 5-1: Permissible wire cross-section

Wire description

Wire cross-section

Minimum

Maximum

Conductor cross section solid 0.34 mm² 2.5 mm²

Conductor cross section flexible 0.2 mm² 2.5 mm²

Conductor cross section flexible, with ferrule without

plastic sleeve

0.25 mm² 2.5 mm²

Conductor cross section flexible, with ferrule with

plastic sleeve

0.25 mm² 2.5 mm²

Conductor cross section AWG 24 12

2 conductors with same cross section, solid 0.2 mm² 1 mm²

2 conductors with same cross section, stranded 0.2 mm² 1.5 mm²

2 conductors with same cross section, stranded,

ferrules without plastic sleeve

0.25 mm 1 mm²

2 conductors with same cross section, stranded,

TWIN ferrules with plastic sleeve

0.5 mm² 1.5 mm²

AWG according to UL/CUL 30 12

The required wire stripping length is 10 mm.

Power supply and output signal connection

The EZ 1000 converter requires a -24 V DC power supply and is typically supplied by the

used measuring amplifiers such as an A6500-UM Universal Measurement Card. Usage of a

suitable external power supply is also possible.

If using an external power supply, ensure that it is a Class 2 power supply or a Limited

Energy source in accordance to CSA 61010-1-12.

Figure 5-4

exemplifies the connection of an EZ 1000. The shown grounding concept is one

possibility. Adapt the grounding concept to the on-site requirements.

Loading...

Loading...