Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

30 Mentor MP User Guide

www.controltechniques.com Issue: 3

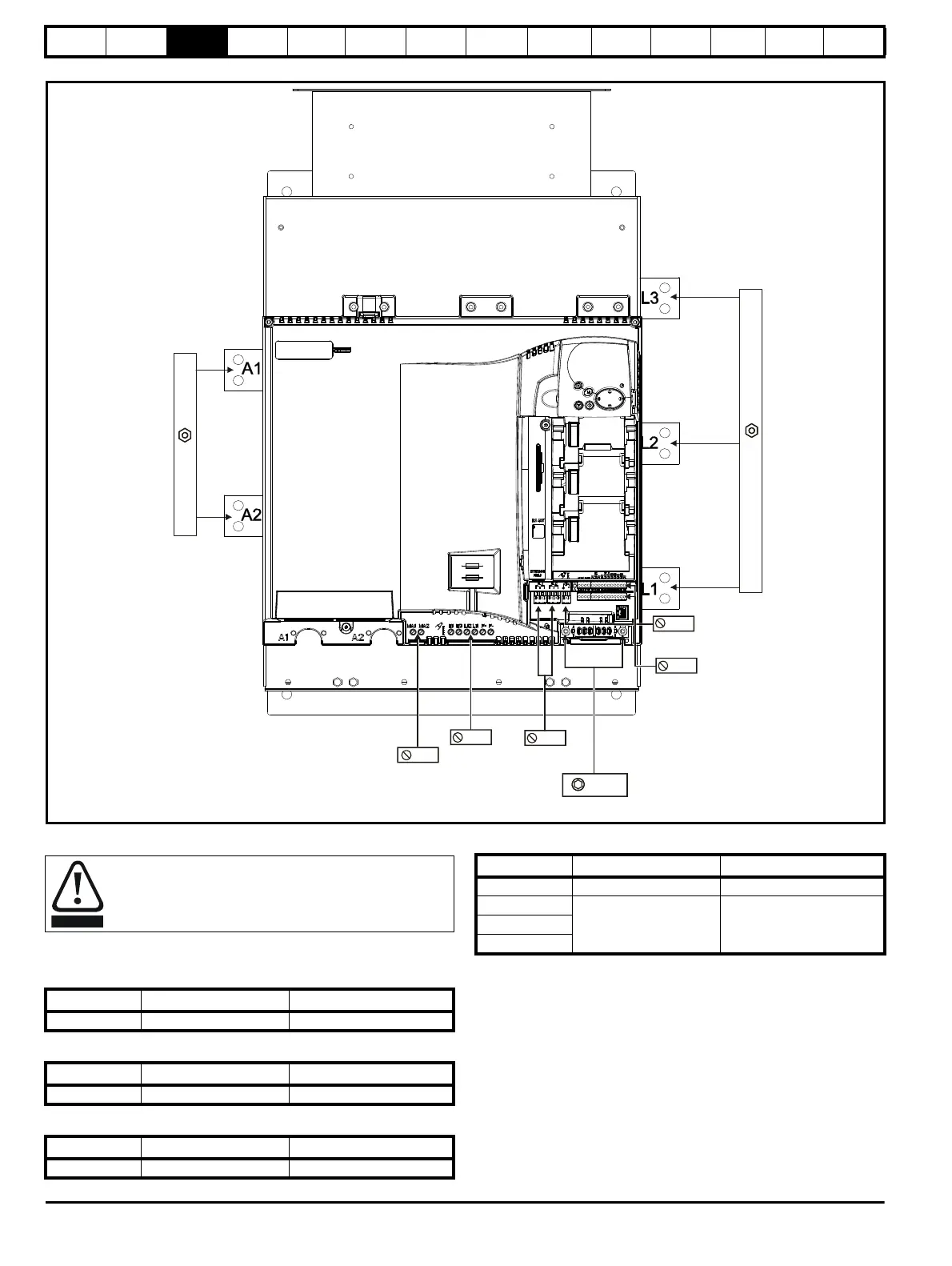

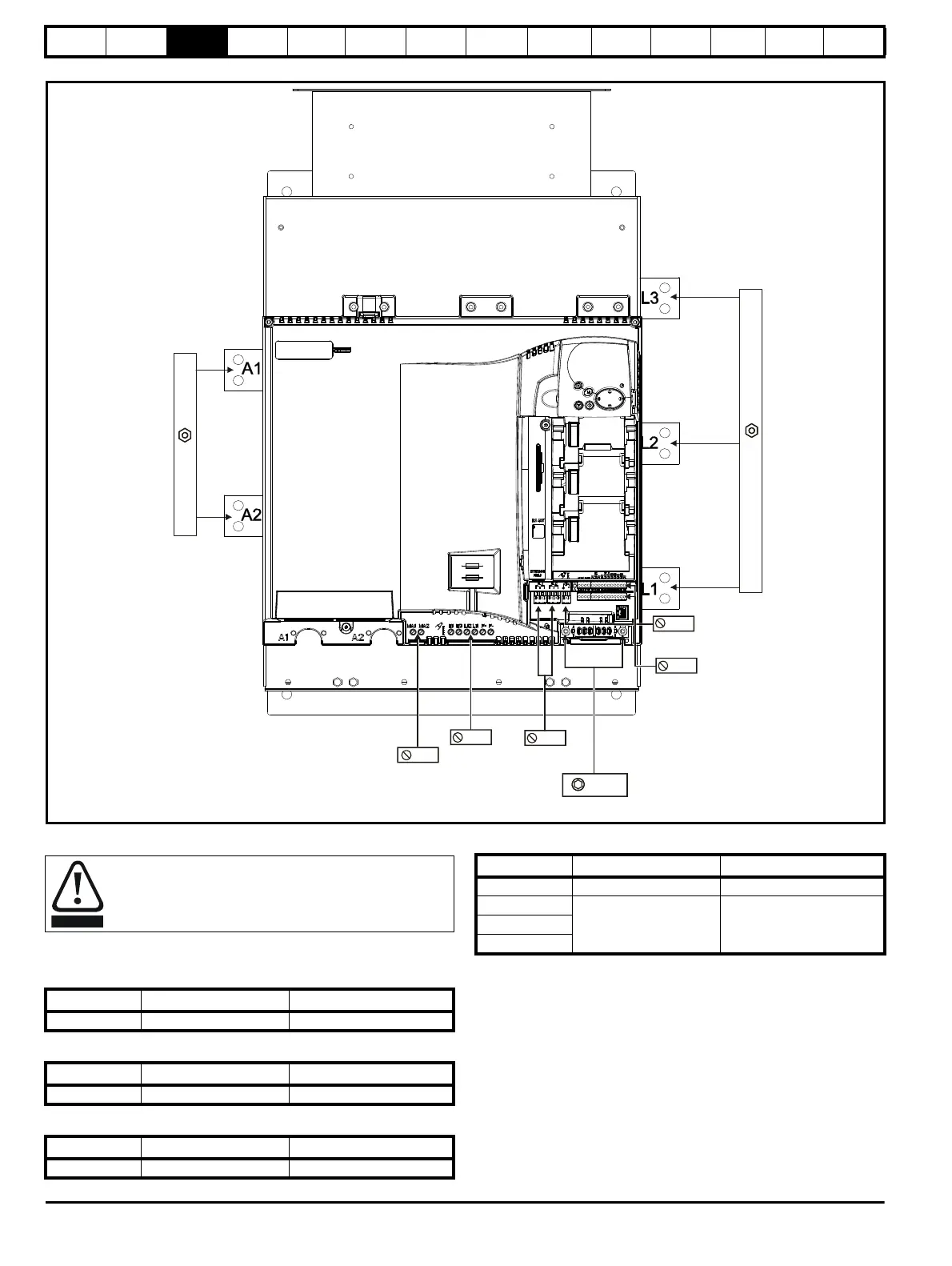

Figure 3-21 Location of the power and ground terminals on size 2C and 2D drives

3.9.2 Terminal sizes and torque settings

3.9.3 Torque settings

Table 3-1 Drive control, status relay and encoder terminal data

Table 3-2 Drive auxiliary and machine armature terminal data

Table 3-3 Drive power stage terminals on size 1 drives

Table 3-4 Drive power stage terminals on size 2 drives

Size 2C / 2D:

M12 nut 19mm AF

5mm

Machine

terminals

5mm

Auxiliary

connections

Relay

connections

Size 2C / 2D:

M12 nut 19mm AF

AC Input

DC Output

To avoid a fire hazard and maintain validity of the UL listing,

adhere to the specified tightening torques for the power and

ground terminals. Refer to the following tables.

Model Connection type Torque setting

All Plug-in terminal block 0.5 Nm 0.4 lb ft

Model Connection type Torque setting

All Terminal block 0.5 Nm 0.4 lb ft

Model Connection type Torque setting

All M8 stud 10 Nm 7.4 lb ft

Model Connection type Torque setting

Size 2A M10 stud 15 Nm (11.06 lb ft)

Size 2B

M12 stud 30 Nm (22.12 Ib ft)Size 2C

Size 2D

Loading...

Loading...