4 – 1

Section 4 • Operation

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

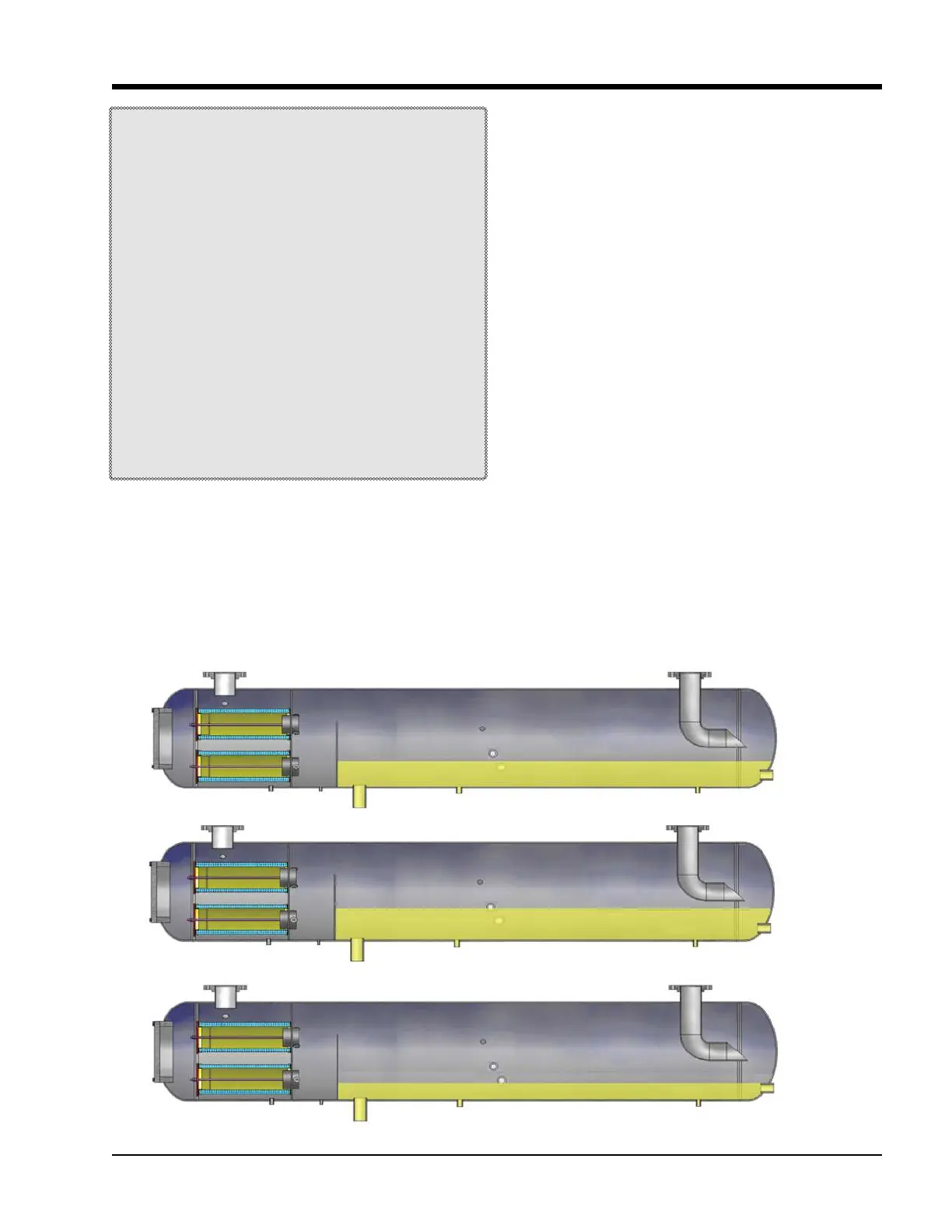

Normal Operating Level

Maximum NON-Operating Level

Minimum Operating Level

Operation

All operation (set-point adjustments, calibrations,

moni toring) of the compressor unit is done through the

mi cro-processor. For additional procedural information,

re fer to micro-processor manual (35391SC for Vission

20/20 Operating Manual or 35391CM for Compact

Logix PLC Software Manual).

Figure 4-1. Oil Operating Levels

WARNING

Software programming credentials shall only be

made available by the supplier. The user will only

have access to operational features established by the

supplier. Failure to comply may result in serious injury

or death.

Oil Inspection

WARNING

Avoid skin contact with any liquid refrigerant or oil.

Wear rubber gloves and a face shield when working

with liquid refrigerant or oil. Failure to comply may

result in serious injury or death.

WARNING

Avoid skin contact with oil. Wear rubber gloves and a

face shield when working with oil. Failure to comply

may result in serious injury or death.

Inspect oil level through sight glasses on the oil separa-

tor, see Figure 4-1. Oil Operating Levels. Drain or ll oil

as required. For oil draining and lling procedure, see Oil

Charging and Oil Draining in Section 5.

Notice on Using Non-Vilter Oils

CAUTION

Do not mix oils. Failure to comply may result in

damage to equipment.

NOTICE

Vilter does not approve non-Vilter oils for use with

Vilter compressors. Use of oils not specifi ed or

supplied by Vilter will void the compressor warranty.

Due to the need for adequate lubrication, Vilter recom-

mends only the use of Vilter lubricants, designed spe-

cically for Vilter compressors. Use of oil not specied or

supplied by Vilter will void the compressor warranty.

Please contact your local Vilter representative or the

Home Ofce for further information.

Loading...

Loading...