4 – 8

Section 4 • Operation

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

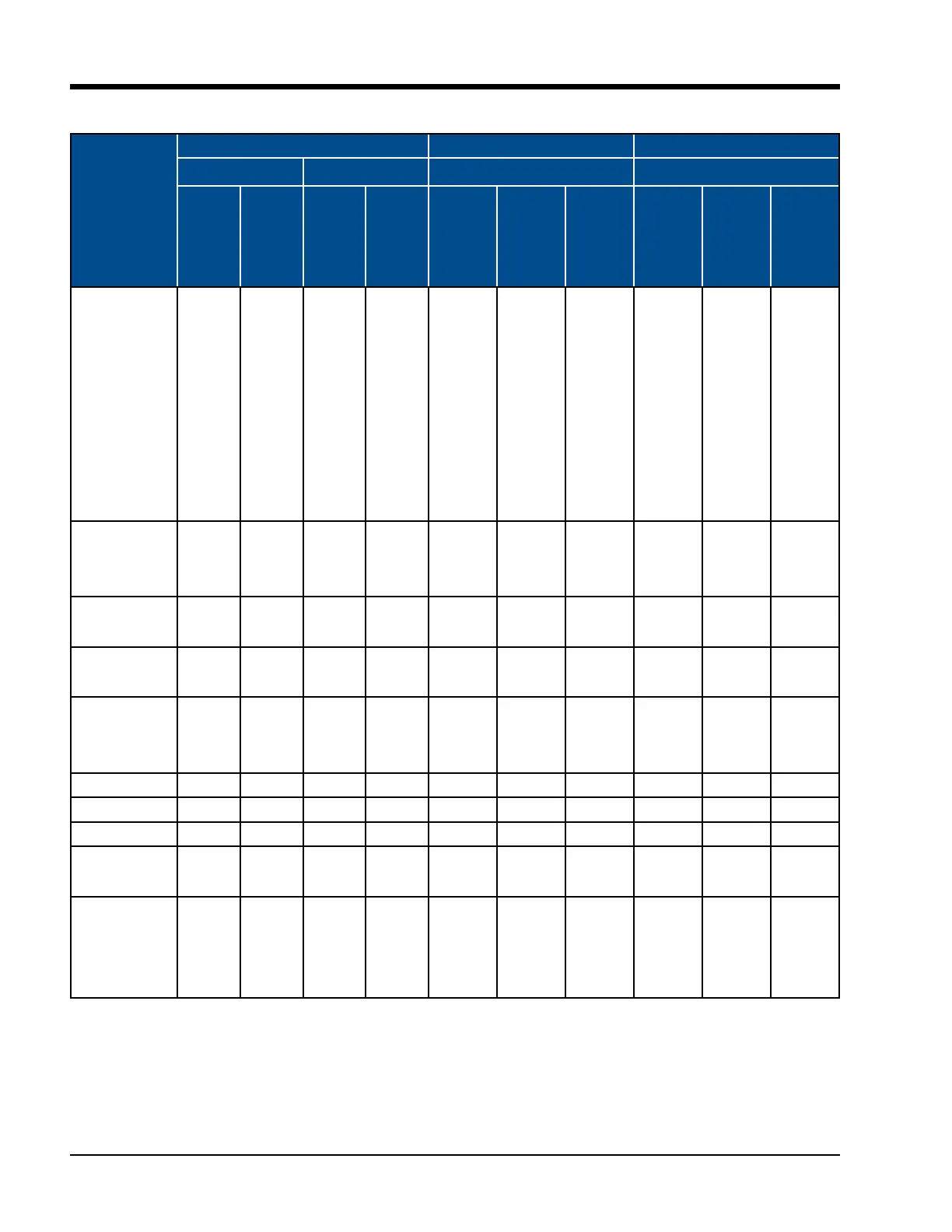

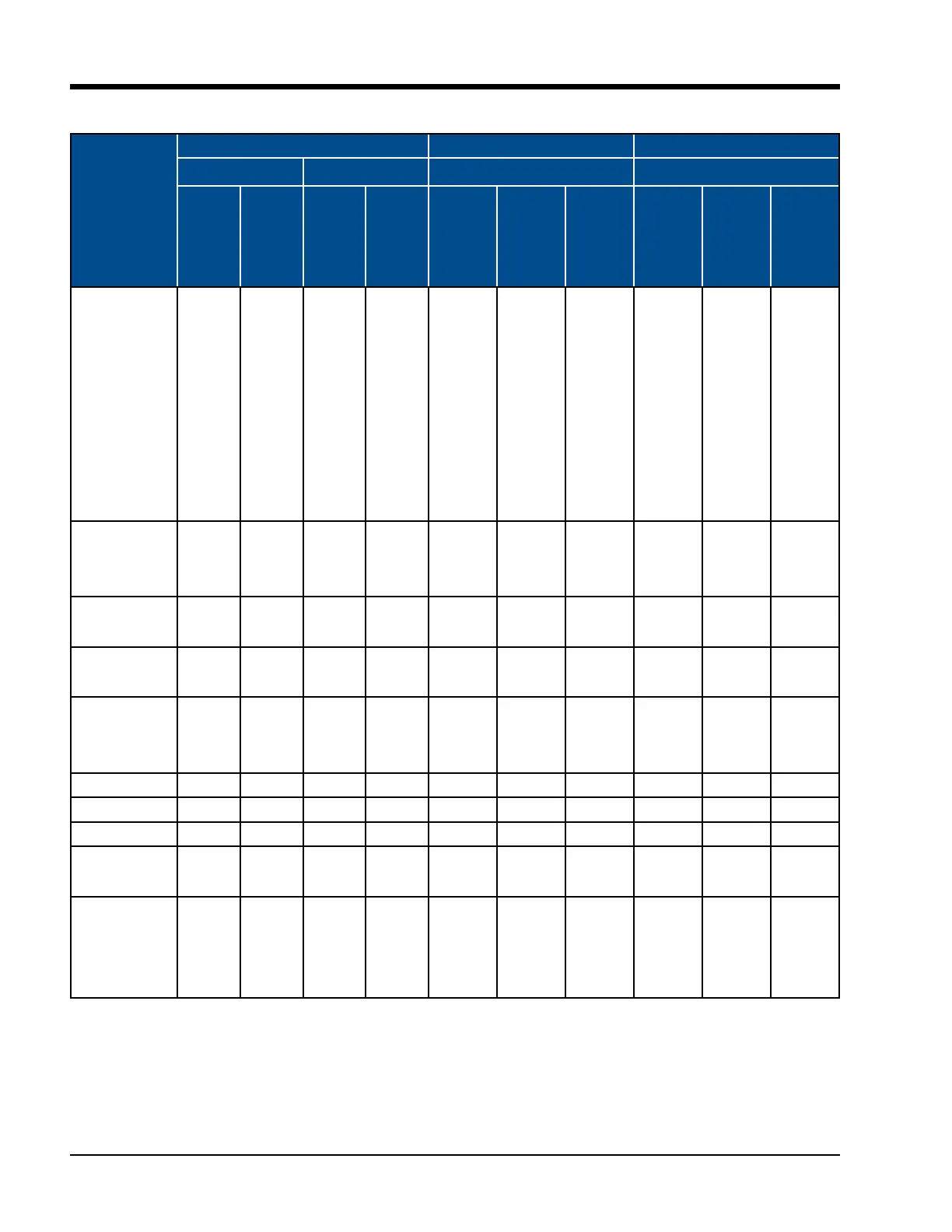

Compressor

Model

Command Shaft Rotation No. of Turns/Rotation Angle/Slide Travel

Capacity Volume Capacity Volume

INC DEC INC DEC Turns Degrees Travel Turns Degrees Travel

VSM 71

VSM 91

VSM 101

VSM 151

VSM 181

VSM 201

VSM 301

VSM 361

VSM 401

CW CCW CW CCW 0.80 288 3.141” 0.45 162 1.767”

VSM 501

VSM 601

VSM 701

CCW CW CCW CW 0.91 328 3.568” 0.52 187 2.045”

VSS 451

VSS 601

CW CCW CW CCW 0.91 328 3.568” 0.52 187 2.045”

VSS 751

VSS 901

CCW CW CCW CW 1.09 392 4.283” 0.63 227 2.473”

VSS 1051

VSS 1201

VSS 1301

CCW CW CCW CW 1.22 439 4.777” 0.74 266 2.889”

VSSC 1501 CCW CW CCW CW 1.36 490 5.325” 0.82 295 3.200”

VSS 1551 CCW CW CCW CW 1.48 533 5.823” 0.87 313 3.433”

VSS 1801 CCW CW CCW CW 1.36 490 5.325” 0.82 295 3.200”

VSS 1851

VSS 2101

CCW CW CCW CW 1.48 533 5.823” 0.87 313 3.433”

VSS 2401

VSS 2601

VSS 2801

VSS 3001

CCW CW CCW CW 1.80 648 7.072” 1.36 490 5.341”

Table 4-1. Command Shaft Rotation Specications*

*The large gear on the command shaft has 50 teeth. The teeth are counted when moving the command shaft from the

minimum stop position to the maximum stop position.

The manual operating shaft on the gear motor should be turned the opposite direction of the desired command shaft

rotation.

The capacity and volume control motors are equipped with a brake, if it is necessary to operate the control motors manu-

ally, the brake must be disengaged. The brake can be disengaged by pushing on the motor shaft on the cone end. The shaft

should be centered in its travel. Do not use excessive force manually operating the motor or damage may result.

Loading...

Loading...