• Gloss differential may be exhibited especially when printing on a coated stock or on a high-density image.

• Colour or density variation among prints or on a print may be caused depending on paper being used or print

environment.

• Due to its high temperature and pressure at image adhesion process, prints may exhibit some paper-wave.

• Variation in Colour registration may be observed depending on ambient environment condition, paper types

used, paper weights etc

Print Quality & Colour Management

• The appearance of the document displayed on the monitor screen may not match the output print because the

monitor uses RGB colour space parameters.

• The customer is responsible for calibrating the Color C60/C70.

• For imported RGB images, optimal colour is achieved in the EPS format. Other imported file formats may produce

unexpected results.

• The specification for colour to colour mis-registration is equal to or less than 95 microns, evaluated on Colotech +

90gsm uncoated paper. Colour to colour mis-registration may vary outside of the specification when using

heavyweight papers above 90gsm.

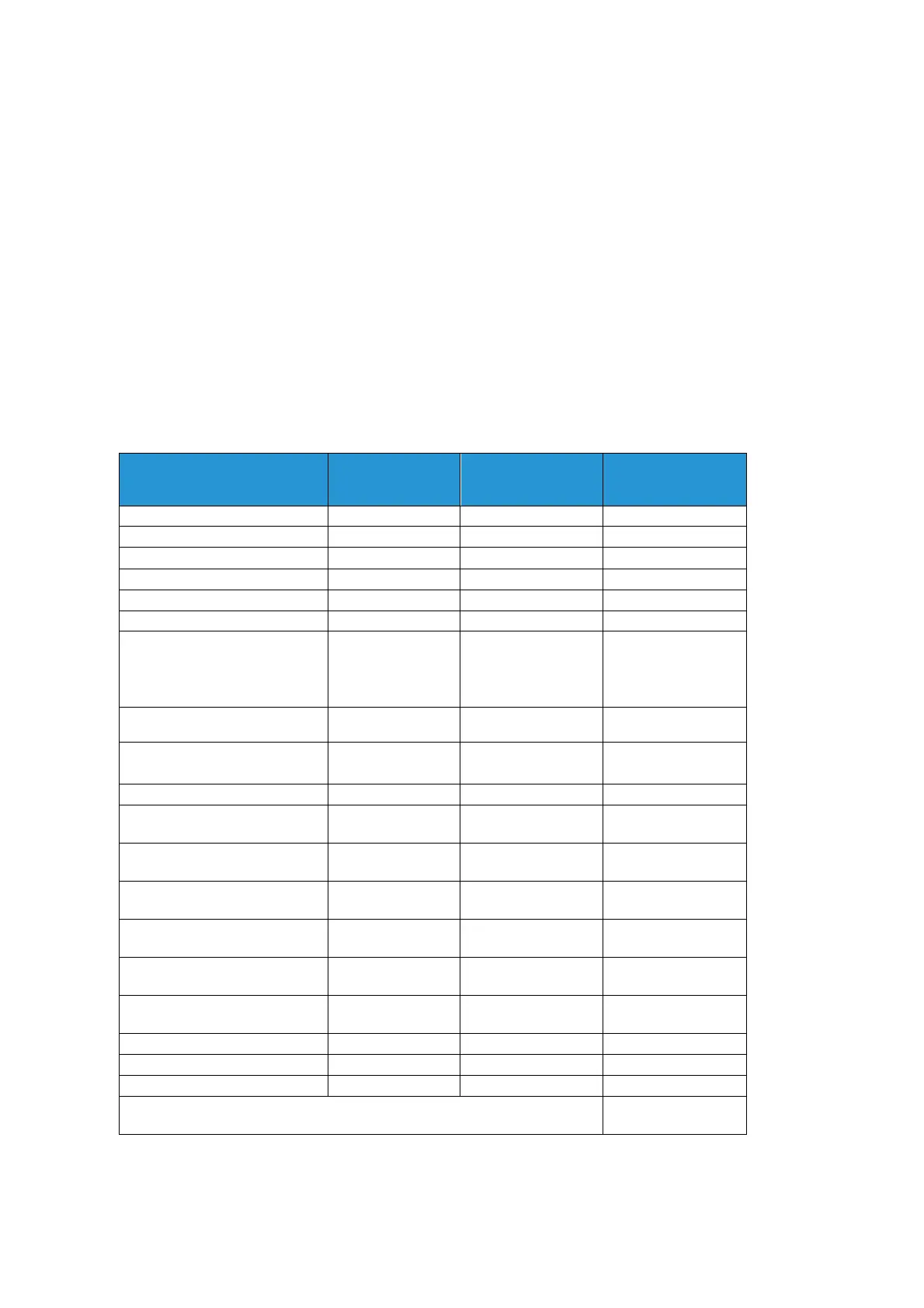

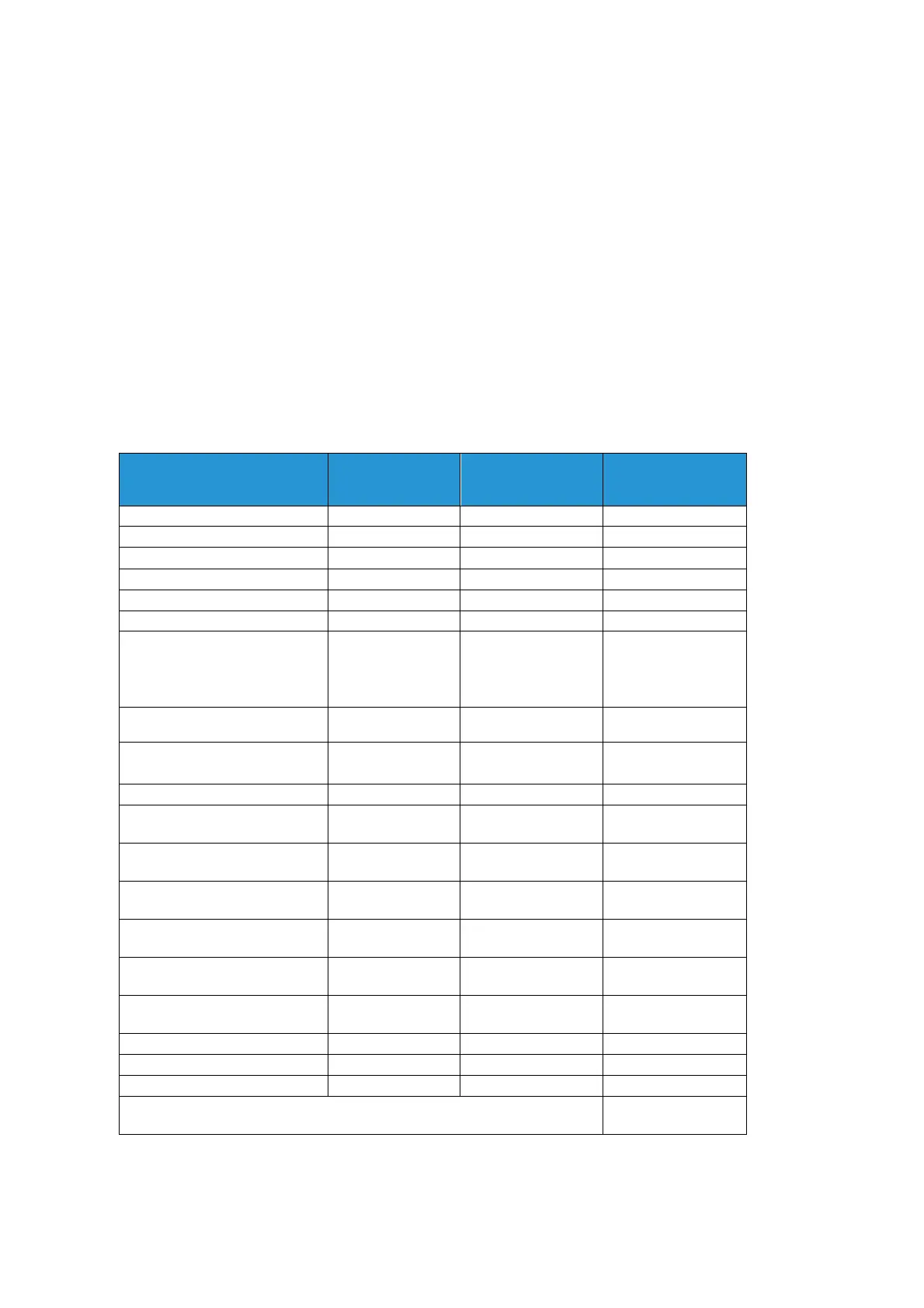

Registration Specifications

Trays 1-4 includes

OHCF (Trays 6-7)

Platen

Skew along the Lead Edge (200mm)

Skew along the Side Edge (400mm)

Image Loss

• Lead Edge

• Trail Edge**

• Side Edge**

Side 1-2 Registration (Lead Edge

Direction)

Side 1-2 Registration (Side Edge

Registration)

Horizontal R/E Precision (280mm)

Applicable for 100%

Horizontal R/E Precision (280mm)

Applicable for 25 to 200%

Horizontal R/E Precision (280mm)

Applicable for 201 - 400%

Horizontal R/E Precision (400mm)

Applicable for 100%

Horizontal R/E Precision (400mm)

Applicable for 25 - 200%

Horizontal R/E Precision (400mm)

Applicable for 201 - 400%

Linearity (Vertical) 400mm span

Linearity (Horizontal) 280mm span

Linearity (Diagonall) 280mm span

* For paper <260mm long and <128 g/m2

** Add magnification variation for Trail and Side Edge

Effect of paper shrinkage due to environmental changes are not included.

Loading...

Loading...