Flying Shear for Roll Forming machines – Instruction manual Pag. 25 / 29

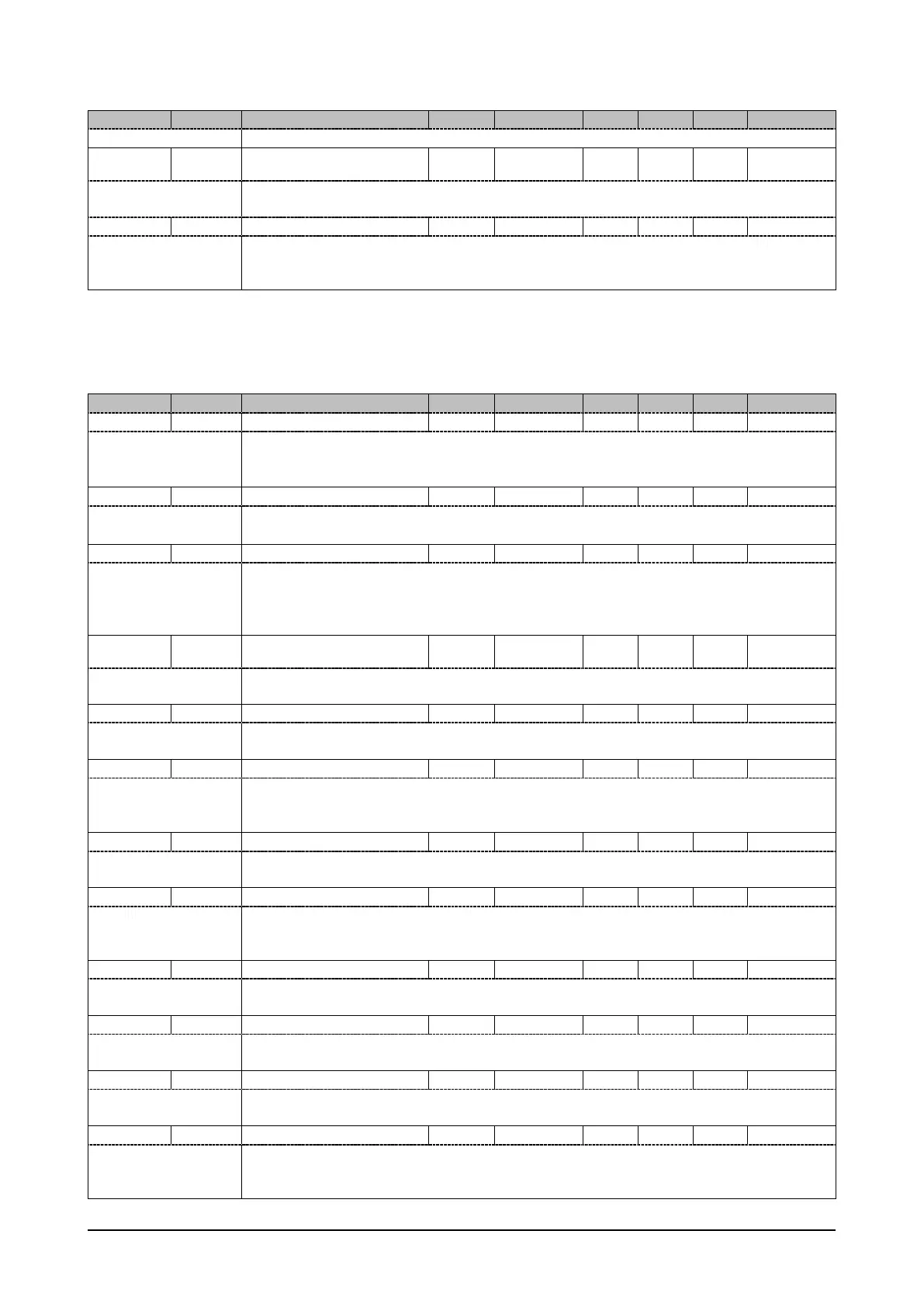

Manual reset of the material count.

Setting the maximum line speed. The calculated line speed will be limited to this

parameter.

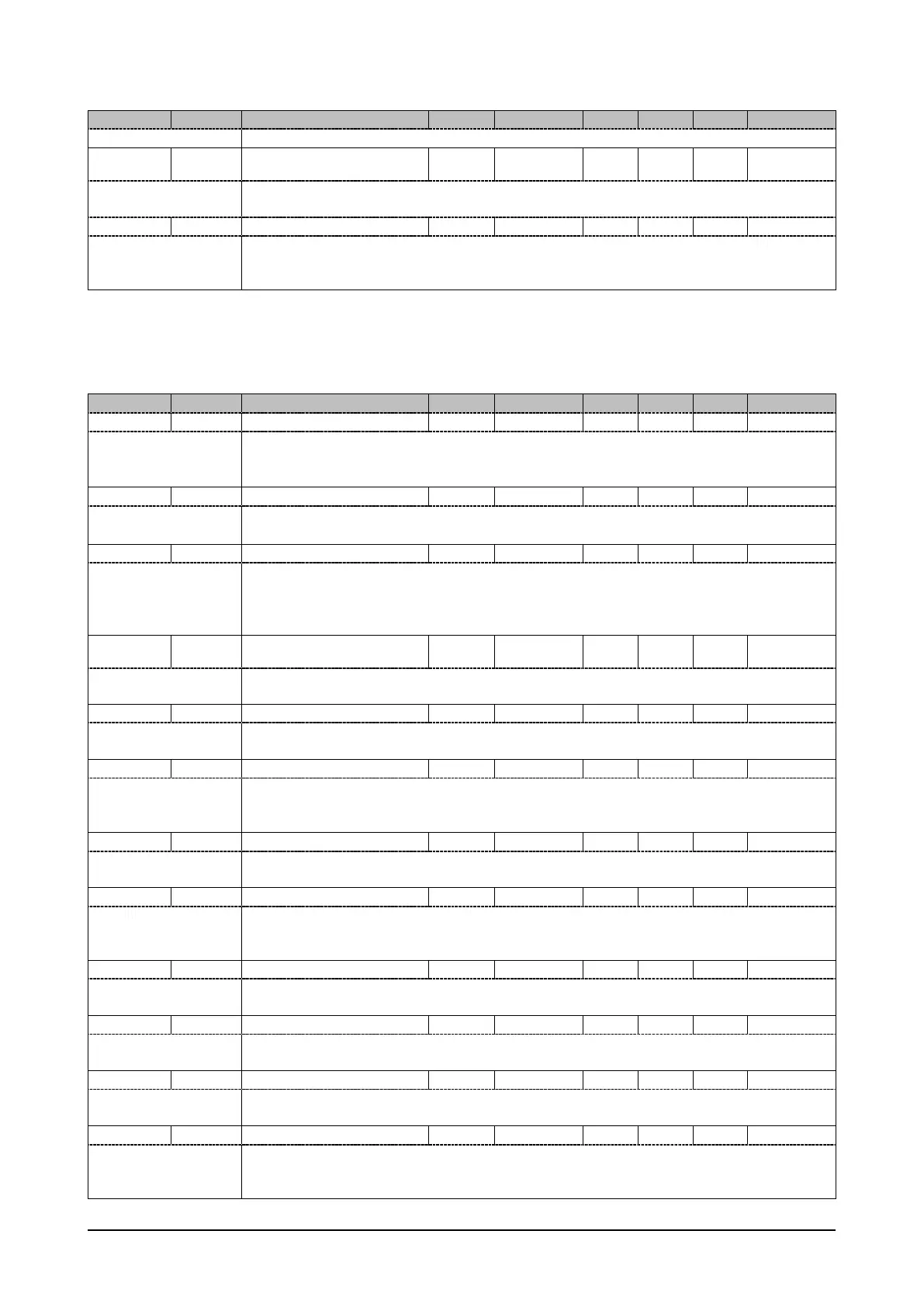

26.09 Trolley

This function allows the parameters that manage the trolley and the immediate manual cut to be set..

Maximum speed the trolley can return from the end of the line to the beginning to

perform a cut.

Proportional gain of position ring.

The space used by the shear to stop once the cut has been completed. This space

is added to the Trolley Limit pos (PAR 11704) to set the maximum stroke of the

shear.

Encoder source mounted on the motor for shear movement.

Mechanical coefficient to define the metric advancement per motor shaft revolution..

Trolley movement limit, with respect to the zero-point defined by Homing. This

parameter defines the useful stroke for the trolley..

Safety margin for the cut time (the total cut time will be given by the sum Cut time +

Margin cut time).

Acceleration ramp for trolley movement..

Deceleration ramp for trolley movement.

Possibility of defining an over-acceleration that can be used when the trolley returns..

The amount of material that runs out of the machine to support the header, once the

cut has been made, with the shear in standby.

Loading...

Loading...