Flying Shear for Roll Forming machines – Instruction manual Pag. 26 / 29

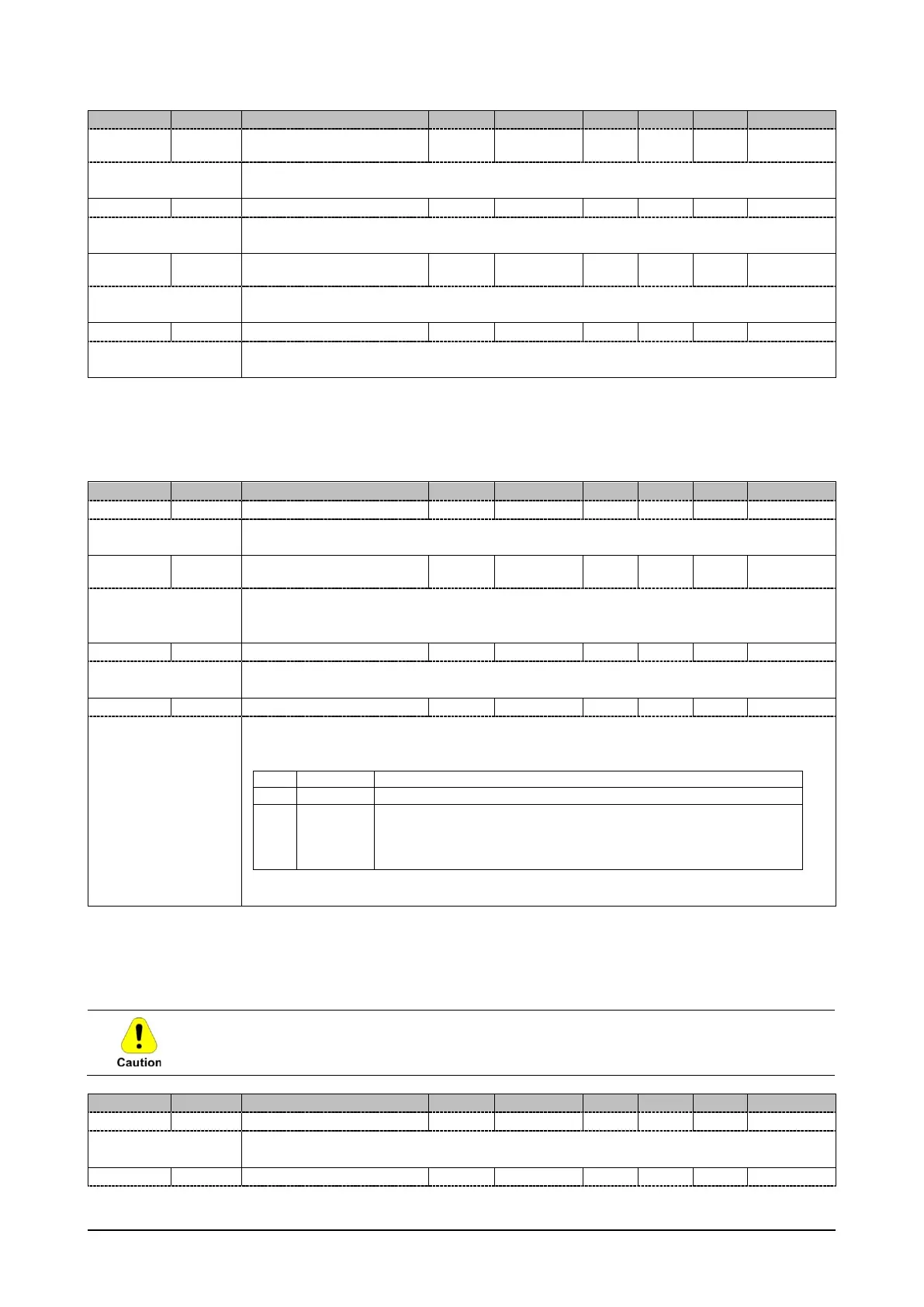

Source of the low blade sensor, i.e. in the end of cut position.

Enabling the high blade sensor.

Source of the high blade sensor, i.e. in the rest position.

Cut command destination..

26.10 Line

This function allows the parameters that manage the line to be set.

Encoder source mounted on the metric wheel to measure the material at the shear

input..

Mechanical coefficient to define the metric advancement per metric wheel revolution.

Selection of the mode for saving the length of the material present in the machine

after switching it off..

The measurement is saved in each phase of shear movement.

The measurement is only saved during the return phase (from the

end to the start of the line).

This allows more precise repositioning the next time the drive is

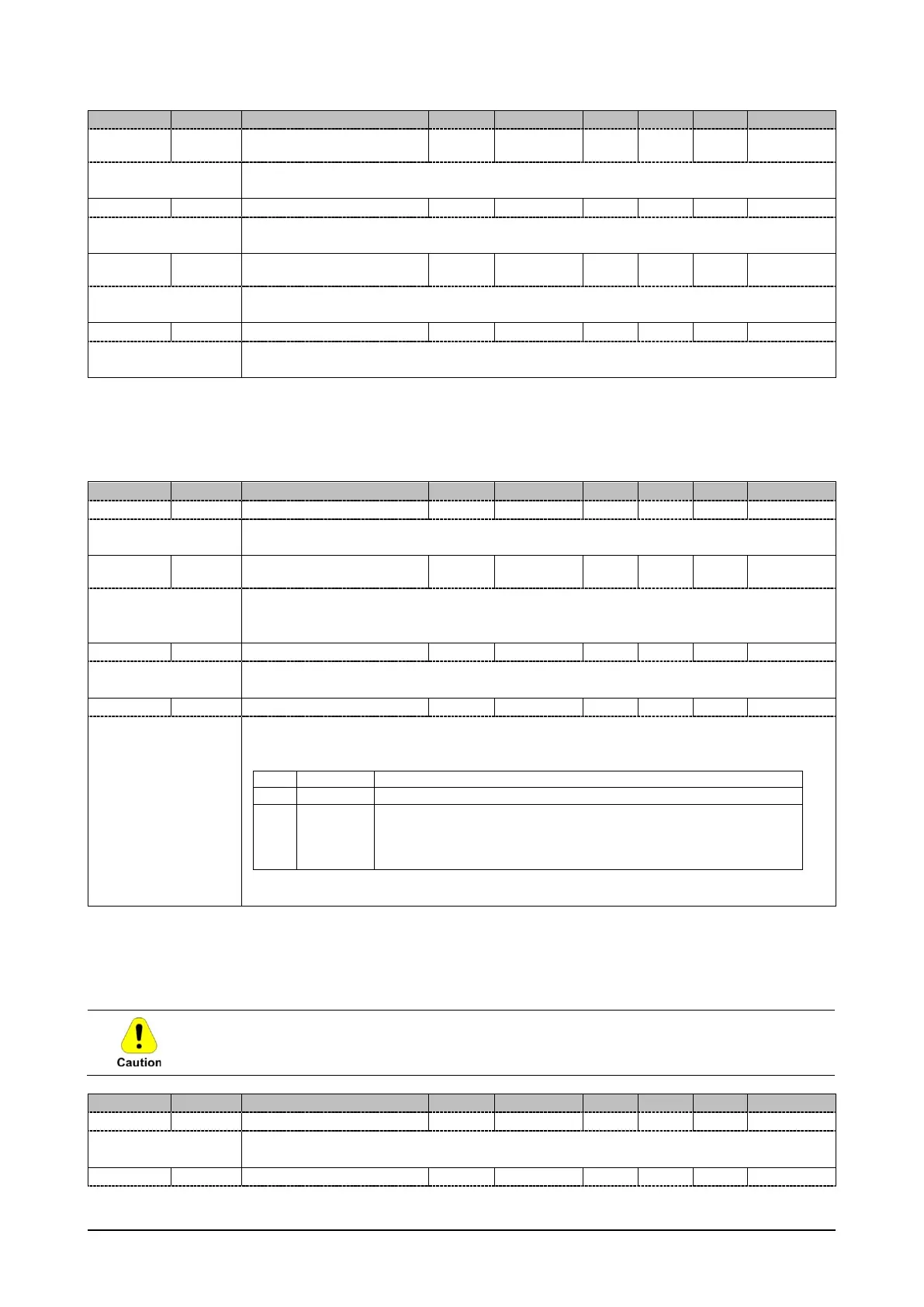

26.11 Alarm

This function allows the application alarm signals to be managed.

If an application alarm is tripped, it has no effect on the drive. The PLC makes the decision on the

action to be taken

Maximum permissible delay between the command and the execution of the cut.

Loading...

Loading...