Flying Shear for Roll Forming machines – Instruction manual Pag. 29 / 29

6 Application alarms

The application carries out a series of checks on itself while it is functioning. The information is stored in the

Word alarm mon (PAR 12052) parameter.

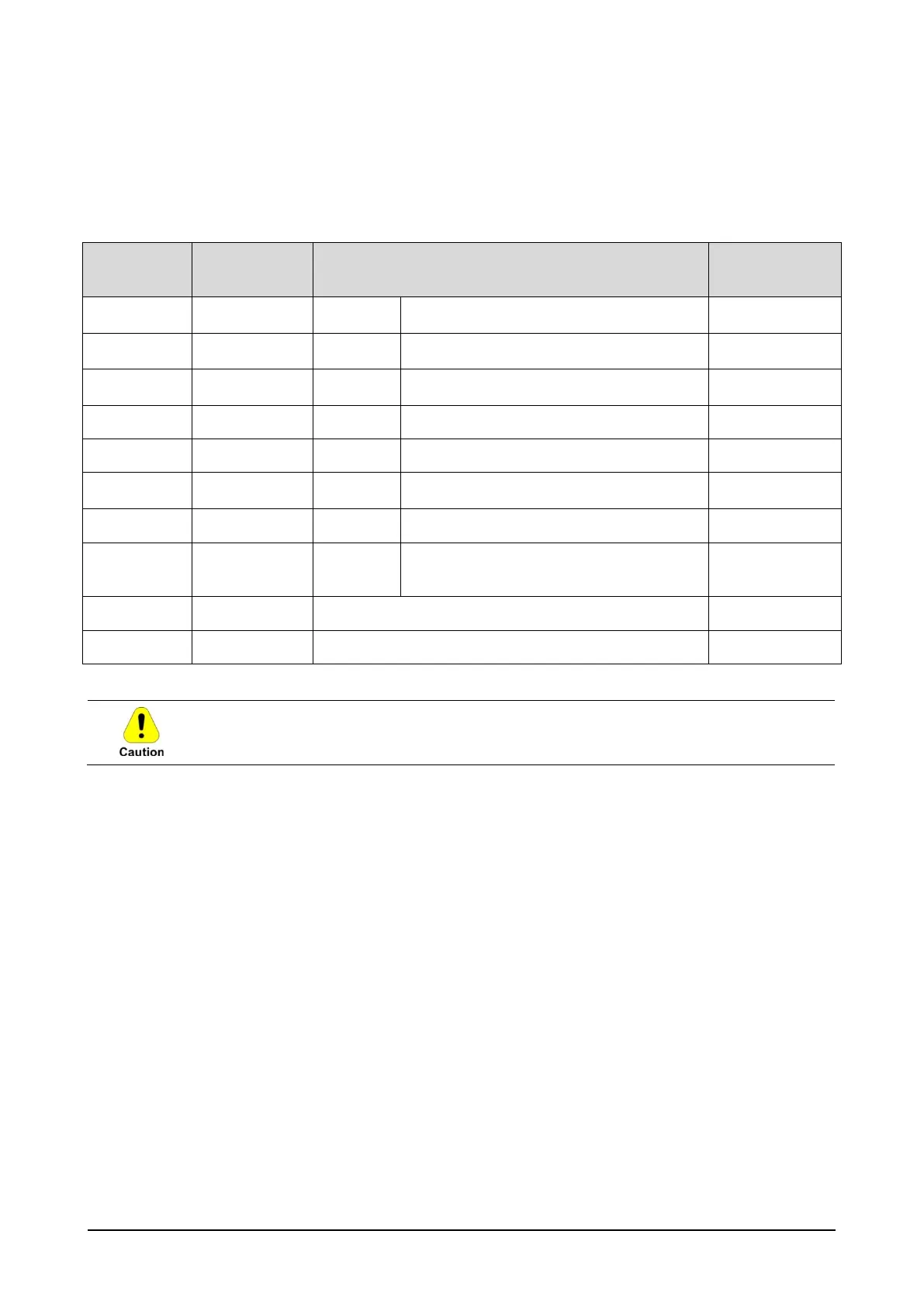

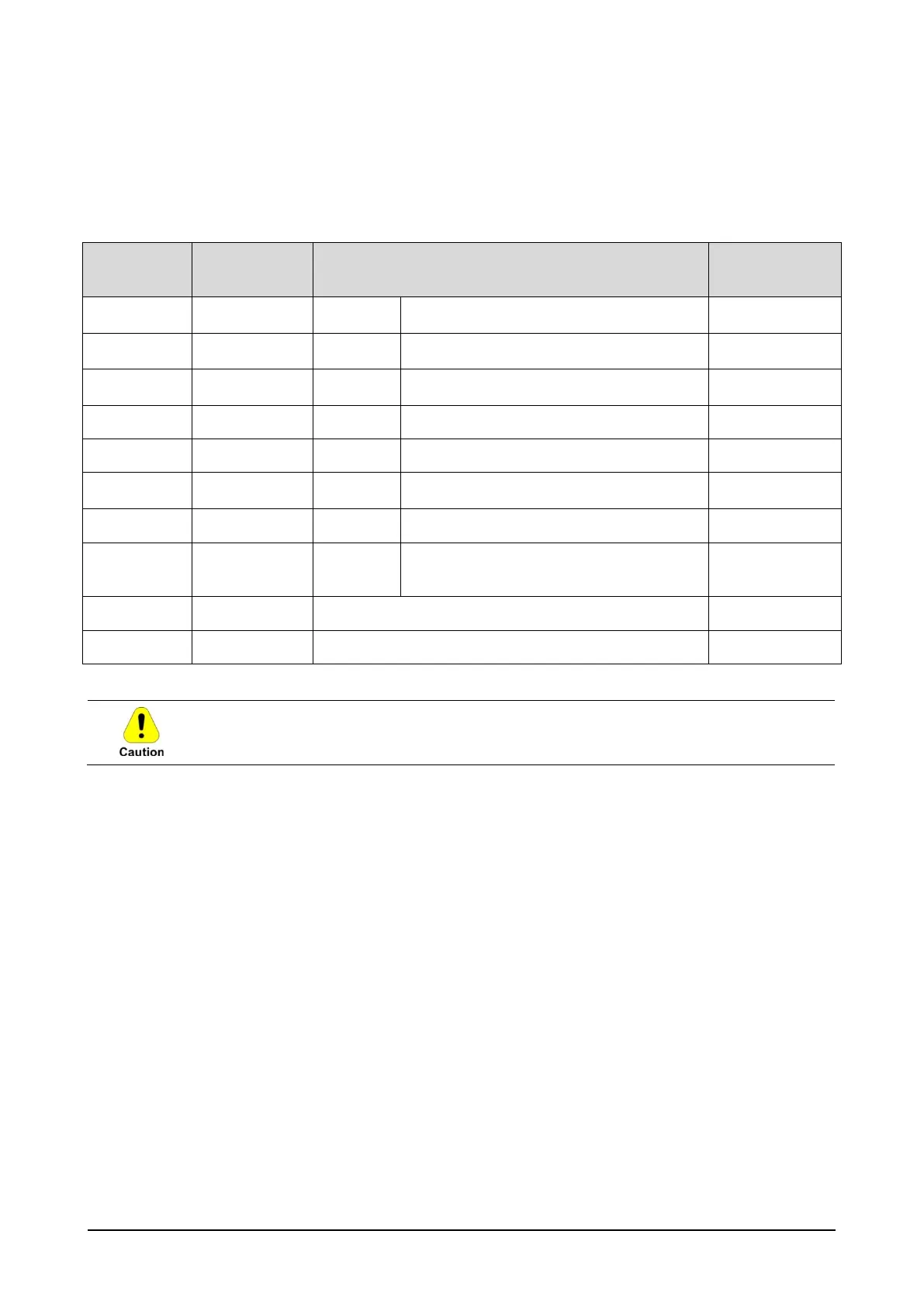

The table shows the application-specific alarms:

ALARM CAUSE

BIT NUMBER

ALARM CAUSE

DESCRIPTION ACTION

0 0x0001

Cut

Consistency check between cut

commands and blade position.

Signalled

1 0x0002

Auto

Alarm during the automated cycle.

Signalled

2 0x0004

Cut length

Cutting does not meet the required

tolerances.

Signalled

3 0x0008

Pos min

Trolley exceeds minimum position.

Signalled

4 0x0010

Pos max

Trolley exceeds maximum position.

Signalled

5 0x0020

Sync

Trolley movement not synchronised with

the line.

Signalled

6 0x0040

Fast Stop

Fast Stop commands active.

Stop during ramp

7 0x0080

Pos line

The length of the material (in progress)

inside the machine is excessive and will

not allow the cut.

Stop during ramp

8 0x0100

Not used

9 0x0200

Not used

The alarms indicated as “Signalled” are not generating any direct action on the drive. The PLC will

decide on what action to take.

Loading...

Loading...