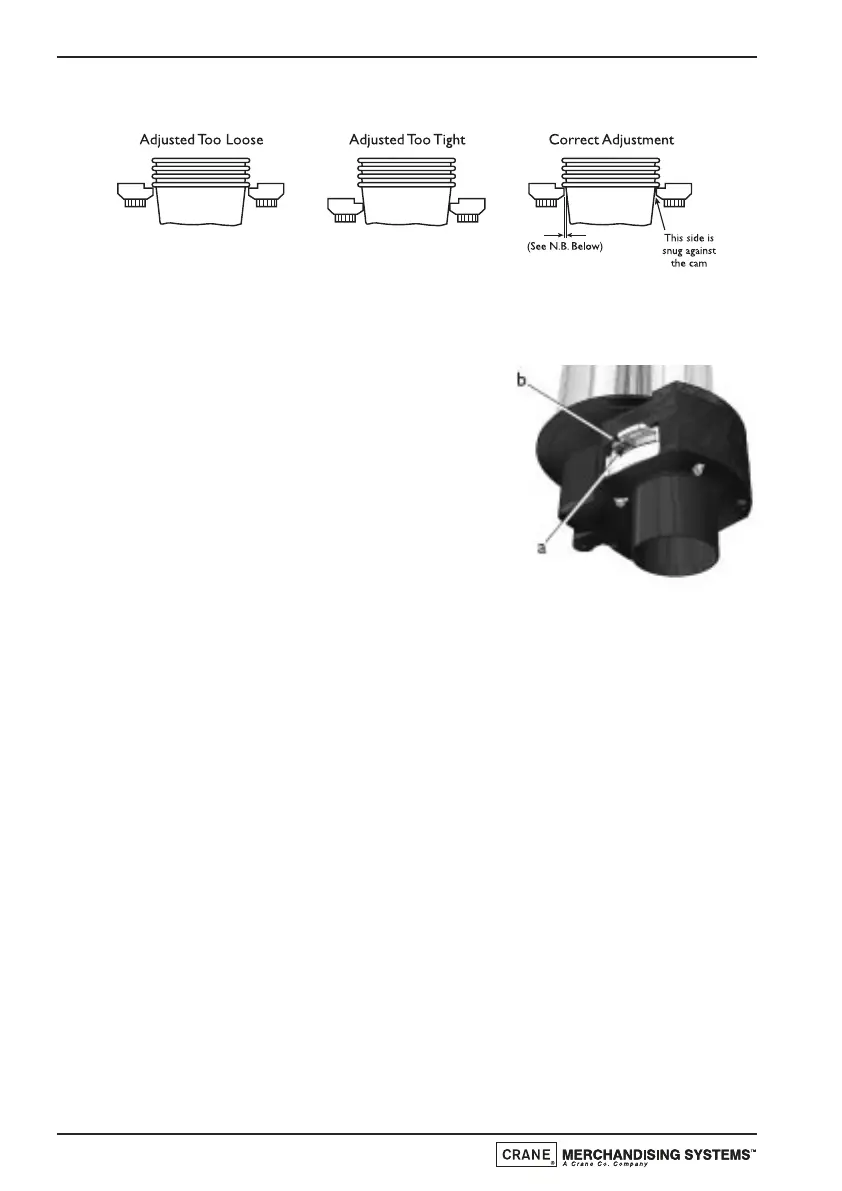

2. Place a minimum of 4 new cups into the cup splitter. Observe the

clearance as shown in the illustration below.

N.B. Clearance indicated in Correct Adjustment diagram should be no

more than half the diameter of the cup lip (maximum) but just enough to

allow for smooth cup ejection.

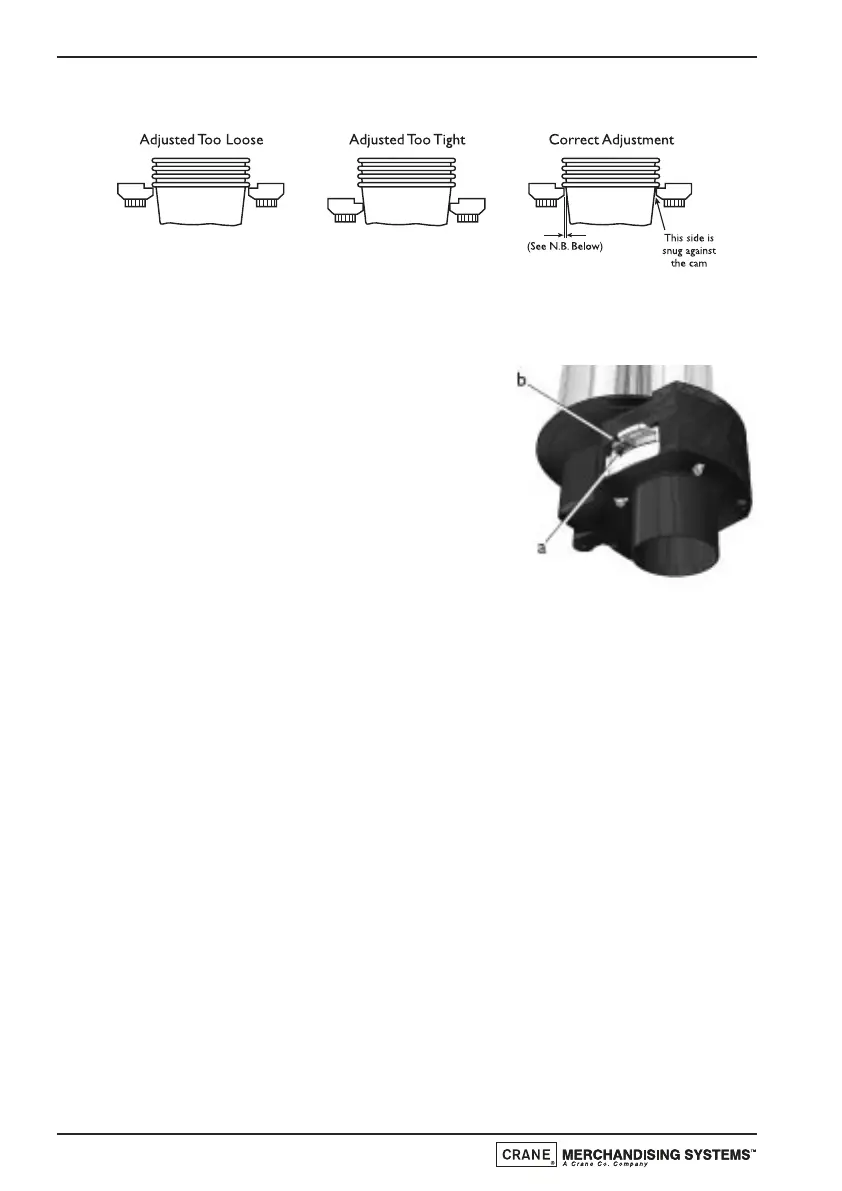

3. If necessary adjust the cup ring to obtain

the clearance as shown. Loosen the

adjustment arm screw (a) and move the

adjustment arm (b) until the correct

clearance is achieved. Hold adjustment arm

in place and retighten the adjustment

screw.

N.B. Move the arm clockwise if adjusting

for larger diameter cups and anti-clockwise

for smaller cups.

4. Switch on the power to the machine using the door switch safety key.

Using the service keypad located in the rear of the door, press the Cup

Test (

button 7) and check that a cup is ejected correctly. Repeat this test

several times to confirm that the mechanism is functioning correctly.

5. Refit the transparent cup sleeves to the cup drop mechanism ensuring that

the flat on the turret motor lines up with the flat in the turret spigot

moulding. Fill the cup sleeves with cups. DO NOT touch cups with your

hands. Allow the cups to drop into the cup sleeves directly from the

packaging.

6. Rotate the cup turret assembly back into its operating position, ensuring

that the unit ‘locks’ into place. Remove the safety key and close the door.

12.5 B2C System Drain Down (B2C Machines)

Should it become necessary for the engineer to work on the B2C water system or

the machine requires draining prior pressure boiler maintenance etc., it is very

important that the following sequence is followed to ensure safe working as well as

correct system fill and heating when the machine is powered up.

Technical Manual

126

Loading...

Loading...