Setup

30 312359R

Connect Explosion-Proof

Heaters

Hazardous location sprayers only

(XM_J_ _ and XM_K_ _)

Ensure wiring, wiring connections, switches, and

electrical distribution panel all meet flame-proof

(explosion-proof) installation requirements.

Refer to your Junction Box manual for the wiring

diagram for hazardous locations.

Refer to your Viscon HP heater manual for electrical

connection instructions and guidelines in hazardous

locations.

Refer to your Viscon HF heater manual for electrical

connection instructions and guidelines in hazardous

locations.

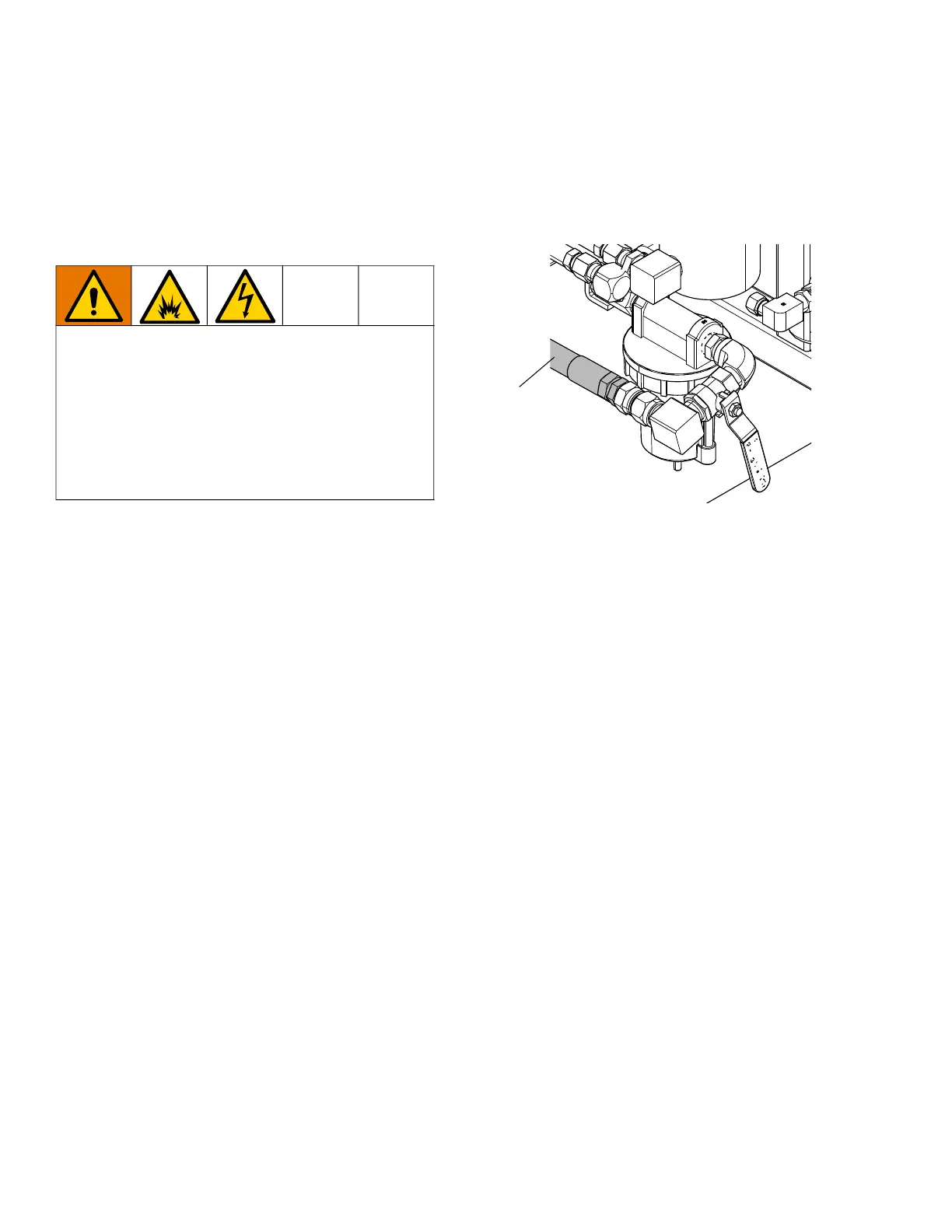

Connect Air Supply

Connect air supply line (SL) to 1.0 in. (10.1 mm) npt(f)

air filter inlet.

Use a 1.0 in. (25.4 mm) ID minimum air hose.

Air supply requirement: 150 psi (1.0 MPa, 10.3 bar)

maximum; 50 psi (0.35 MPa, 3.5 bar) minimum while

running System Verification (page 51), and 80 psi

(0.55 MPa, 5.5 bar) while spraying.

Flow volume required: 70 scfm (1.96 m

3

/min) minimum;

250 scfm (7.0 m

3

/min) maximum. Available fluid

pressure and flow rate are directly related to available

air volume. See Pump Performance Charts, page 102.

General flow volume guidelines:

- 70 scfm (1.96 m

3

/min) per gpm (lpm) while

spraying

- 10 scfm (0.28 m

3

/min) added per agitator

- 10 scfm (0.28 m

3

/min) added per drum feed

pump

If your sprayer is for use in hazardous locations, the

control display (F) is powered by an air-driven alternator.

Dosing valves are operated by air. The dosing valves on

the sprayer will not operate correctly if the inlet air

gauge drops below 80 psi (0.55 MPa, 5.5 bar) while

spraying. The B side dosing valves may not be able to

close, which will result in B overdosing and going off

ratio.

If your sprayer is intended for hazardous locations, a

qualified electrician must connect the explosion-proof

heater wiring. Ensure wiring and installation comply

with local electrical codes and regulations for

hazardous locations.

Improperly installed or connected equipment may

result in fire, explosion, or electric shock. Follow local

codes and regulations.

SL

Loading...

Loading...