Maintenance

312359R 59

Hopper

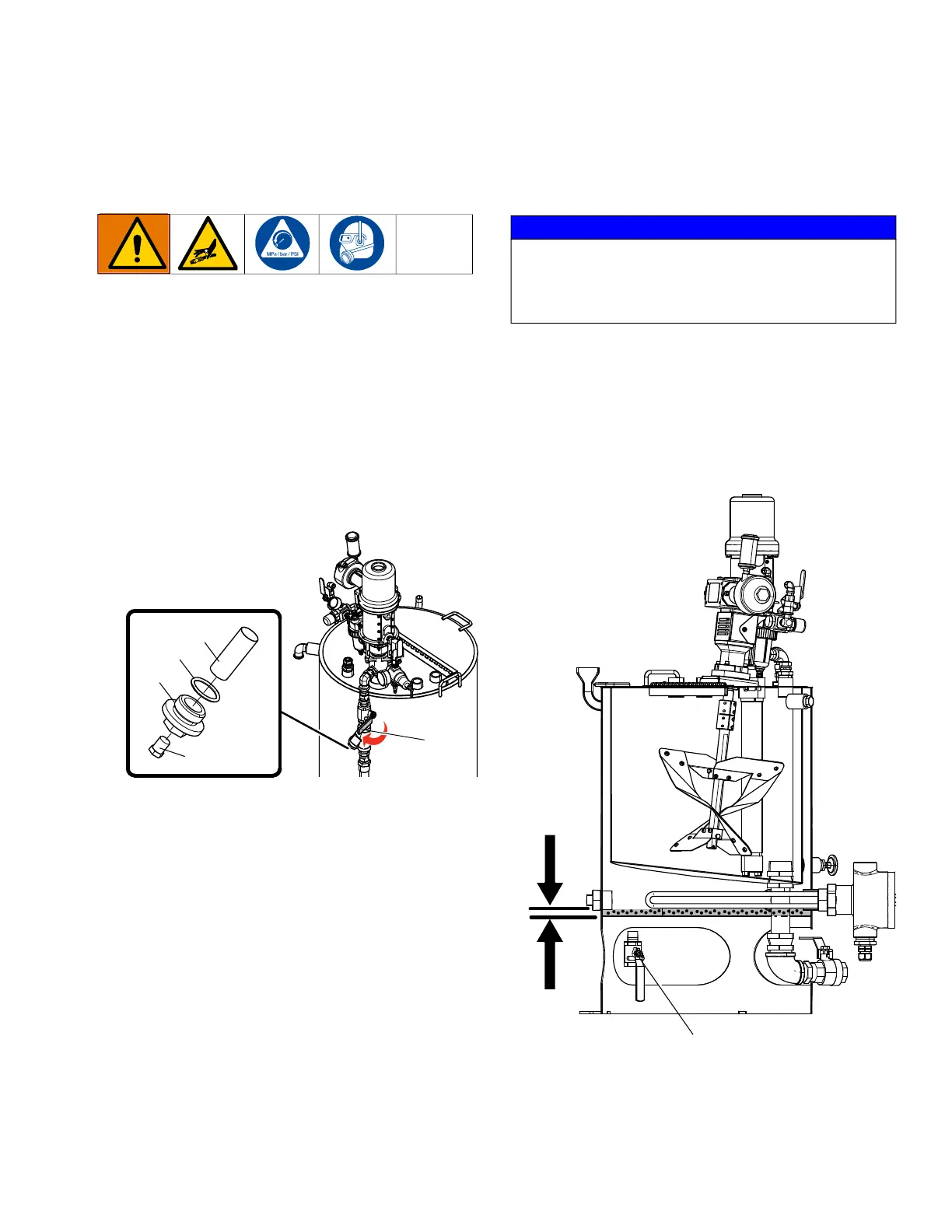

Clean Inlet Strainer Screen

The inlet strainers filter out particles that can plug the

pump inlet check valves. Inspect the screens daily as

part of the startup routine, and clean as required.

1. Ensure that all pumps are shut off and close the

Y-strainer valve (ES).

2. Place a container under the strainer base to catch

drain off when removing the strainer plug.

3. Remove the screen from the strainer manifold.

Thoroughly flush the mesh screen (MS) with

compatible solvent and shake it dry.

4. Inspect the screen. No more than 25% of the mesh

should be restricted. If more than 25% of the mesh

is blocked, replace the screen. Inspect the gasket

and replace as needed. See your heated hopper

manual for replacement components.

5. Ensure that the pipe plug (PP) is screwed into the

strainer plug (SP). Install the strainer plug (SP) with

the mesh screen (MS) and gasket (SG) in place and

tighten. Do not over tighten the strainer plug--let the

gasket make the seal.

6. Open the Y-strainer valve (ES). Ensure that there

are no leaks and wipe the equipment clean.

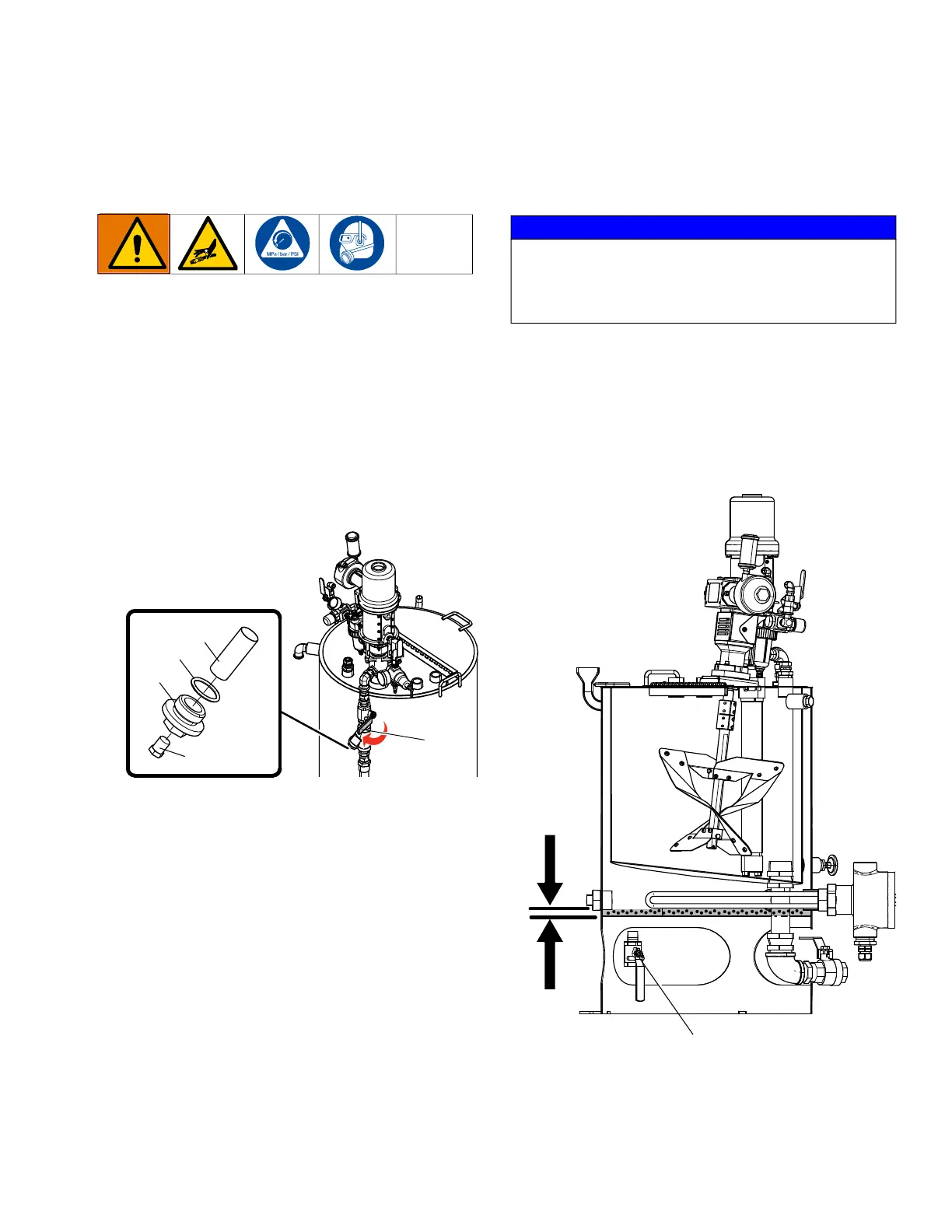

Check Heating Fluid Level

Gradual fluid evaporation can occur. Check the level of

heating fluid monthly. Add fluid as needed.

Drain Heating Fluid

Replace heating fluid once a year to improve heating

efficiency and increase heater element life. Keep the

heating element above the sediment deposits. Sediment

deposits will drain out from the heating fluid drain valve

(EJ).

NOTE: The immersion heater will not operate in

sediment deposits.

SP

SG

MS

ES

PP

NOTICE

Freezing temperatures can cause damage that may

result in the heating fluid leaking into the terminal

enclosure. To avoid damage, do not expose the unit to

freezing conditions.

Maximum

sediment

level

EJ

Loading...

Loading...