Maintenance

60 312359R

Feed Pumps

• Keep the packing nut/wet-cup half filled with Graco

Throat Seal Liquid (TSL

™

) or compatible solvent to

help prolong packing life.

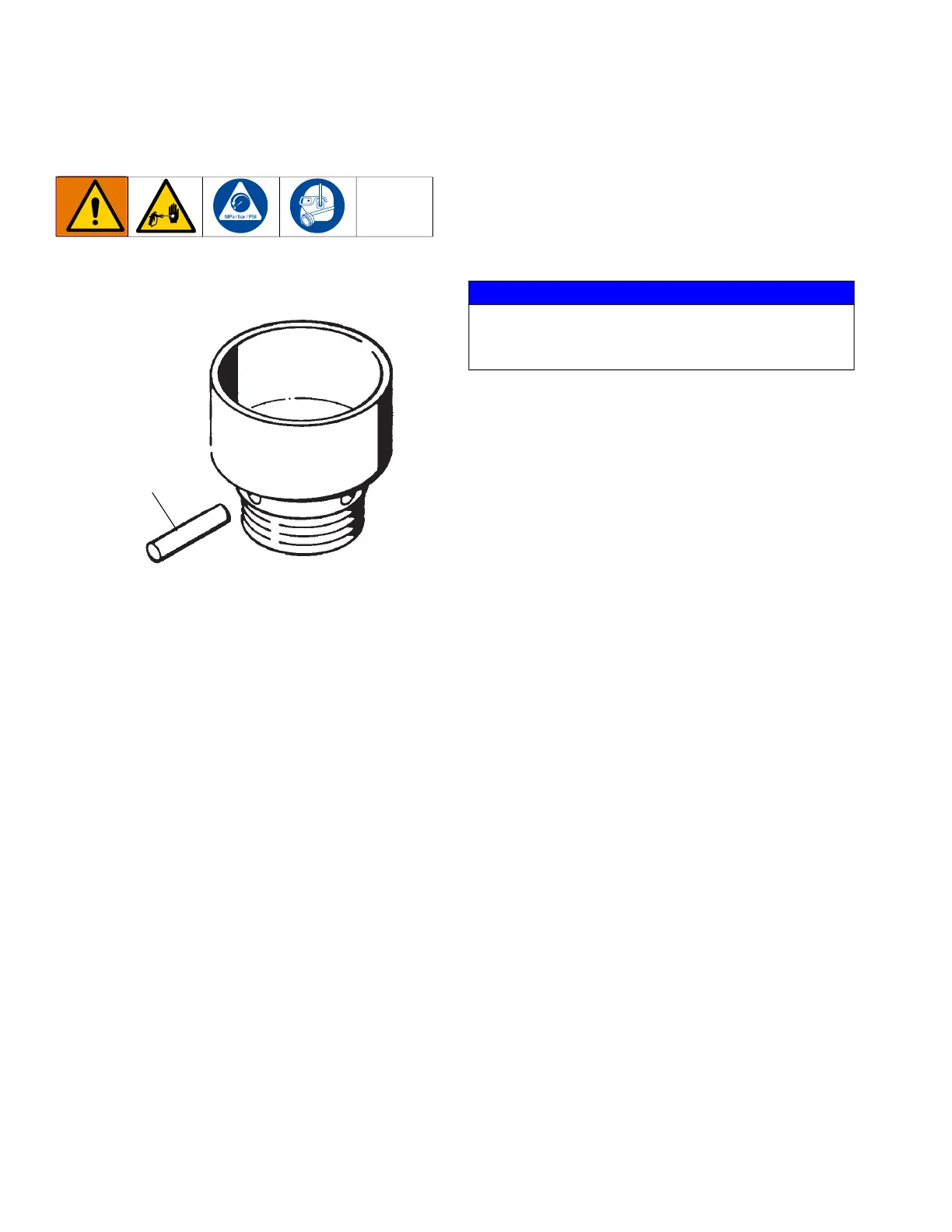

• Adjust the packing nut weekly so it is just tight

enough to prevent leakage. Use a spanner wrench

or a 0.25 in. (6.3 mm) diameter rod to tighten the

nut. Do not over-tighten.

• Never leave the pump or hoses filled with water or

air. To help prevent corrosion, flush the water and all

air out of the system and leave it filed with mineral

spirits or an oil-based solvent.

Agitators

• After the first 100 hours, or two weeks of operation,

change the gear reducer oil. After that, change the

oil every 2500 hours, or six months (whichever

comes first) of operation under normal conditions.

More frequent oil changes are needed under severe

operating conditions or in atmospheres containing

excessive moisture or abrasives. See your agitator

manual for the oil changing procedure.

• If the air motor is operating sluggish or inefficiently,

flush the air motor (see your agitator manual).

• Every 2500 hours, or six months (whichever comes

first) of operation, inspect the bearing block (see

your agitator manual).

0.25 in. (6.3 mm)

Diameter Rod

NOTICE

To prevent air motor failure and possible damage to

equipment, always keep the air motor properly

lubricated using Air Motor Lubricant.

Loading...

Loading...