Providing a Hermetically Sealed Refrigerant Circuit

Leak, Strength and Tightness Testing

General:

The sole purpose of this section is to raise awareness of the different methods

to ensure a sealed system, applicable for GREE Air–Conditioners and to assist

in determining the most appropriate one to use in different situations.

Analysing a system to be free of leaks is the most important activity during RAC

system installation, commissioning , maintenance or service. Having the proper

test equipment is at least half of the job. Unfortunately there are so many meth-

ods of leak detection and so many types of test equipment, no one method fits

every situation, especially if the refrigerant in use is flammable. Decisions need

to be made as to the method used and the type of equipment needed for every

leak to be found.

These conditions make leak testing one of the most challenging tasks faced by

service technicians. In addition, national regulations are requiring service techni-

cians to find leaks, thus not allowing technicians the choice of just adding refrig-

erant to keep the system in operation, which is indeed a dangerous practice for

systems using flammable refrigerants.

Finally, the most important concern, handing over a safe and efficient system to

the client, which has to be hermetically sealed and contains exactly the lowest

amount of refrigerant charge required and is set up and configured to factory

specifications and tolerances.

To provide a sealed refrigerant circuit the following direct refrigerant detection

methods are recommended:

1. Leak Testing with the use of an electronic gas detector

2. Strength Testing by pressurising the system with OFDN

3. Tightness Testing by pressurising the system with OFDN and subsequent

“Bubble Test”

Alternative:

Tightness Testing by pressurising the system with N2/H2 Forming Gas

mixture and the use of a Trace Gas Leak Detector

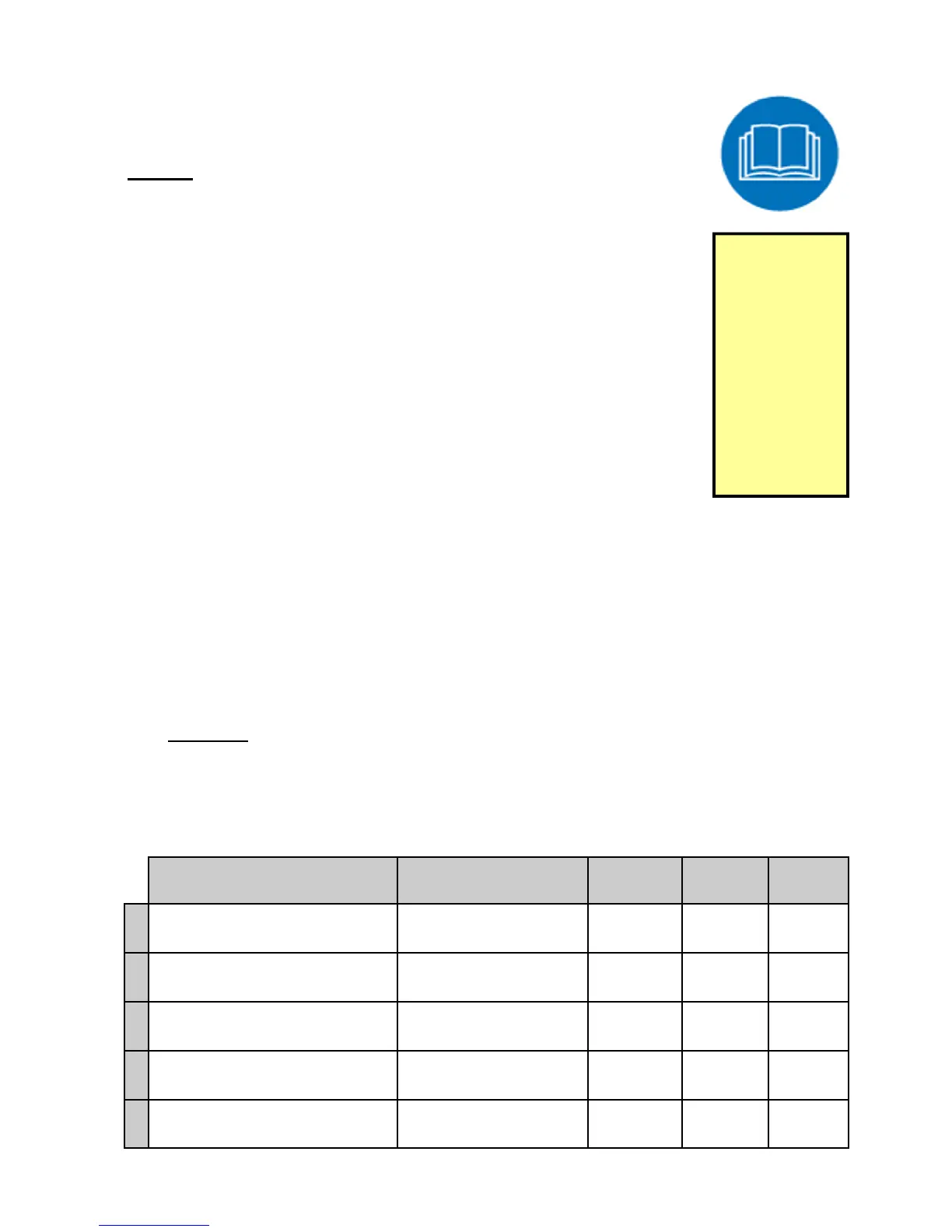

Possible Leak finding methods applicable for GREE Air– Conditioners ser-

vicing:

Best practice is

to combine

different leak

finding

methods to

provide a

hermetically

sealed

refrigerant

circuit!

Combine 2 & 3

and if

necessary + 5

Direct Leak Finding Methods To be used as;

Must have

and do

1

Soapy water bubble test with refrig-

erant pressure (only)

Leak Check

2

Using an HC electronic Leak-

Detector

Leak Test X

3

OFDN pressurised System and

soapy water (Bubble Test)

Tightness Test X

4

N

2

/H

2

Forming gas pressurised sys-

tem and Trace Gas Detector

Tightness Test

5 Pressurising the System with OFDN

Pressure Test > refrigerant

components are replaced

X

Will be

excellent

X

Not recom-

mended

X

Loading...

Loading...