10-21

dummyheaddummyhead

CRANKSHAFT/PISTON/VALVES

VALVE SEAT RECONDITIONING

Inspect the valve seat contact area (page 10-20).

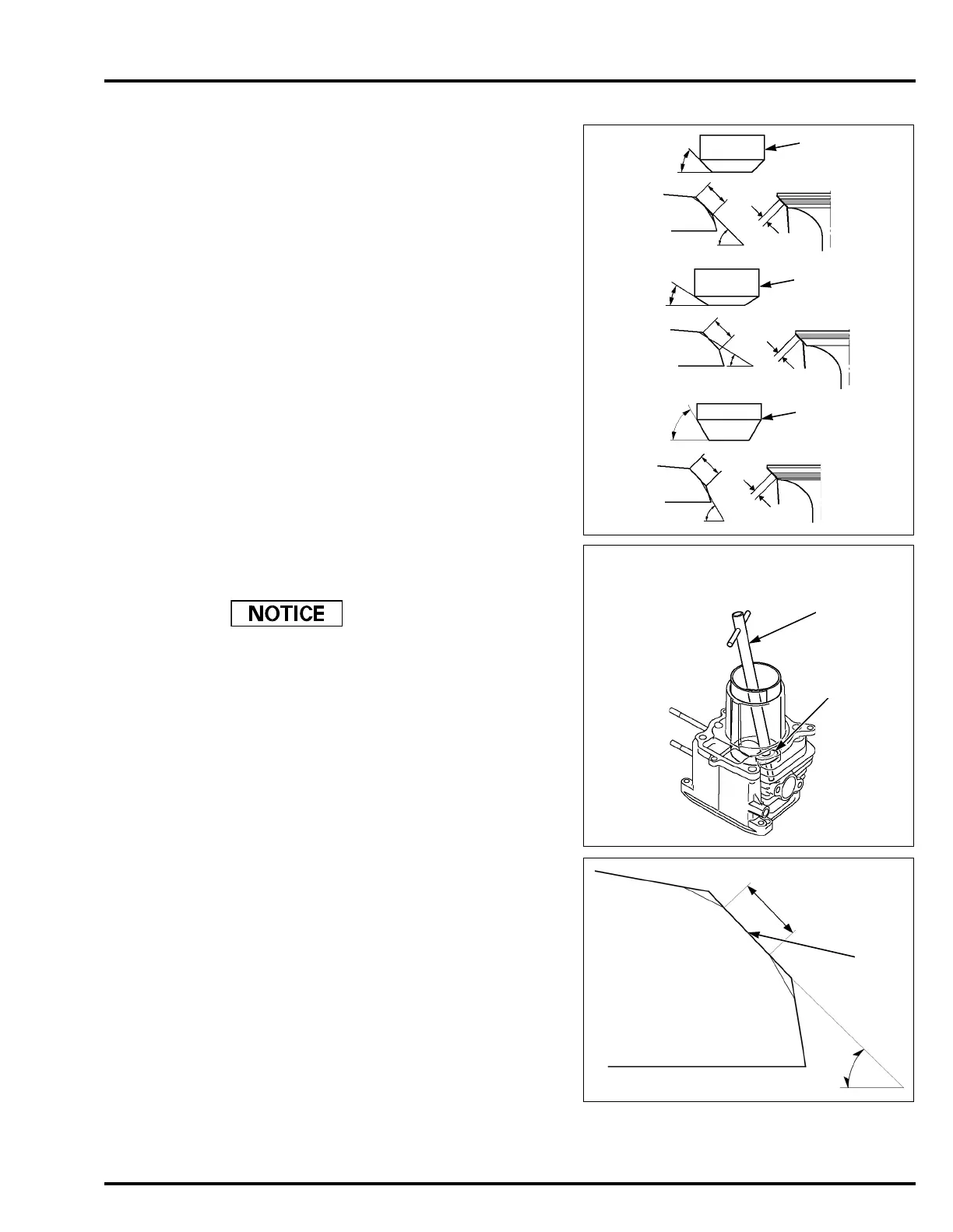

Using a 45° seat cutter [1], remove any roughness or

irregularities from the seat.

If the contact area is too high on the valve, removes

material from the top edge using a 32° flat cutter [2].

If the contact area is too low on the valve, removes

material from the bottom edge using a 60° interior cutter

[3].

Valve seat cutters [1]/grinder or equivalent valve seat

refacing equipment is recommended to correct a worn

valve seat.

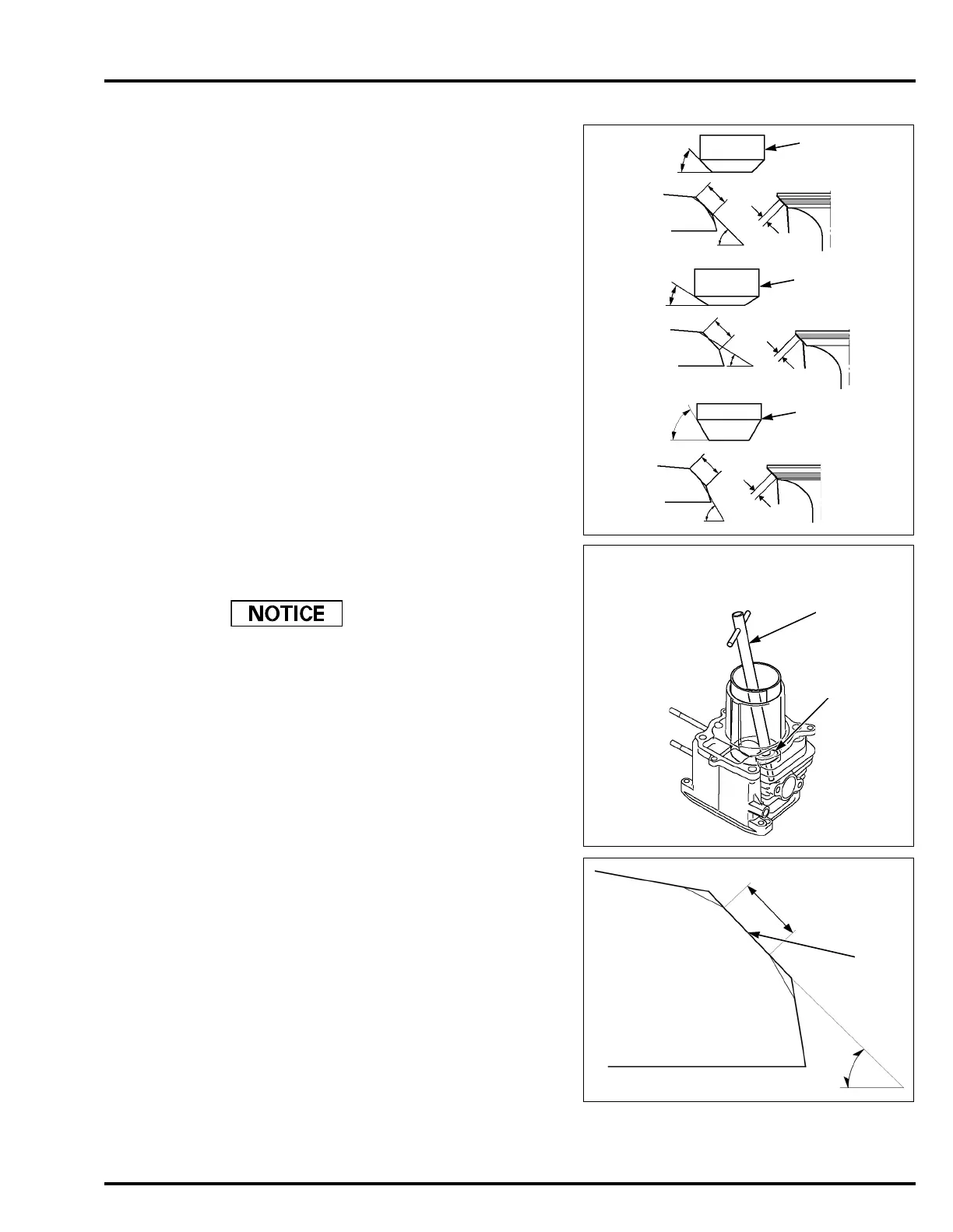

Turn the cutter clockwise, never counterclockwise.

Continue to turn the cutter as you lift it from the valve

seat.

Make a light pass with the 45 ° cutter to remove any

possible burrs at the edge of the seat.

Be sure that the width [1] of the finished valve seat is

within specification.

Thoroughly clean the cylinder to remove any cutting

residual.

[1]

VALVE SEAT

TOO LOW

60°

60°

45°

45°

32°

32°

VALVE SEAT

TOO HIGH

[2]

[3]

TOOLS:

Cutter holder, 5.5 mm [2] 07981-VA20101

Seat cutter, 24.5 mm (45 ° IN/EX) 07780-0010100

Flat cutter, 25 mm (32 ° IN/EX) 07780-0012000

Interior cutter, 26 mm (60 ° IN/EX) 07780-0014500

STANDARD: 0.7 – 0.9 mm (0.03 – 0.04 in)

SERVICE LIMIT: 1.8 mm (0.07 in)

Loading...

Loading...