Do you have a question about the Honeywell Apex and is the answer not in the manual?

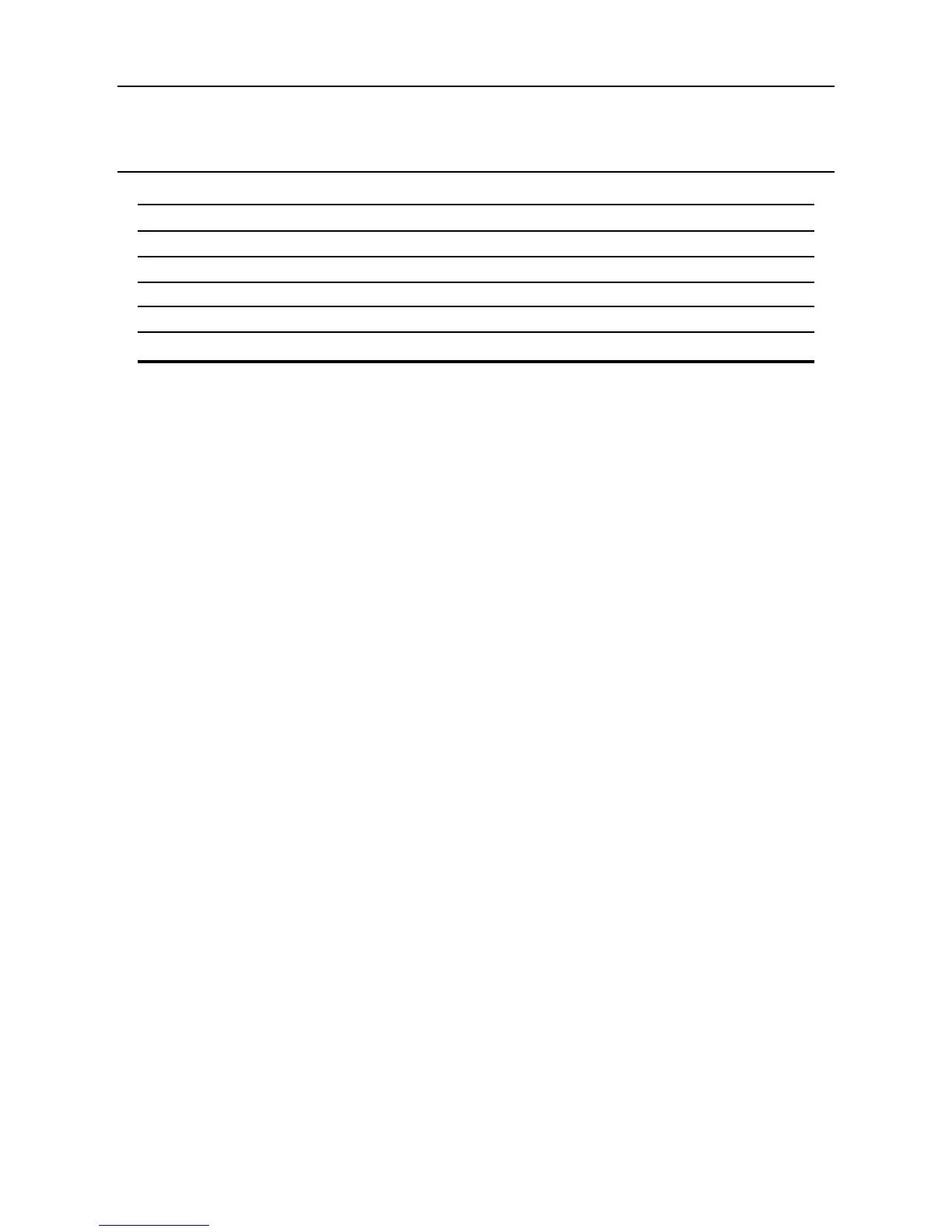

| Type | Addressable Fire Alarm Control Panel |

|---|---|

| Power Supply | 120/240 VAC, 50/60 Hz |

| Operating Temperature | 32°F to 120°F (0°C to 49°C) |

| Humidity Range | 10% to 93% non-condensing |

| Compatibility | Honeywell Notifier devices and compatible peripherals |

| Certifications | UL, FM, CSFM |

Critical safety advice applicable before installation or operation of the equipment.

Specific safety instructions and warnings pertaining to the transmitter unit.

Specific safety instructions and warnings for the certified sensor.

Important precautions and potential risks during installation and operation.

Overview of the manual's sections and explanation of information notices.

Introduction to Transmitter Unit, Certified Sensor, and Accessories.

Description of the certified sensor and its available gas cartridges.

List and brief descriptions of available optional accessories.

Essential points and best practices for proper system installation.

Steps for locally mounting the transmitter and sensor unit.

Procedures for remote sensor mounting using a junction box.

Instructions for installing and connecting the LonWorks communication board.

Procedures for fitting various system accessories like housings and cones.

Explanation of the LCD screen interface and control button functions.

Step-by-step guide for powering up and initialising the unit.

Information on system access levels and password management.

Overview of the system's hierarchical menu structure and navigation.

Procedures for performing gas calibration and related settings.

Settings for alarms, cartridges, digital communications, and language.

Viewing system status, calibration info, and current configuration.

Accessing and managing the unit's event and history logs.

Quick reference list for common operational tasks and their menu paths.

Identifying and resolving system faults and error messages.

Detailed steps for calibrating the gas sensing cartridge.

Procedure for connecting LonWorks boards to the digital network.

Recommended maintenance tasks and their required frequencies.

How to perform maintenance and replace system components.

Detailed technical specifications for the transmitter and sensor.

List of detectable gases and their measurement ranges.

Electrical input power and output signal details.

System logging capabilities for power-ups, faults, and alarms.

Accuracy, drift, response time, and temperature effects.

Operating temperature, humidity, and storage requirements.

Electromagnetic compatibility standards met by the unit.

Housing material, size, weight, and mounting details.

System configuration capabilities for sensors and parameters.

Hazardous area and safety certifications for the unit.

Details on the interchangeable gas sensing cartridges.

List of available cartridges with their part numbers.

Specifics for Catalytic SG16 cartridges for Methane and Propane.

Technical details for various system accessories.

Details on the LonWorks communication interface and network variables.

Hazardous area and safety approvals for the transmitter unit.

Hazardous area and safety approvals for the certified sensor.

Hazardous area and safety approvals for the junction box.

Compliance of accessories with CSA C22.2 No. 152 standard.

Reference to control diagrams for UL and CSA installations.

Catalog of system accessories and their part numbers.

Part number for the LonWorks digital communications board.

Catalog of available spare parts and their part numbers.

Definitions of technical terms used throughout the manual.