EXCEL 50 INSTALLATION INSTRUCTIONS

EN1B-0101GE51 R1105D

38

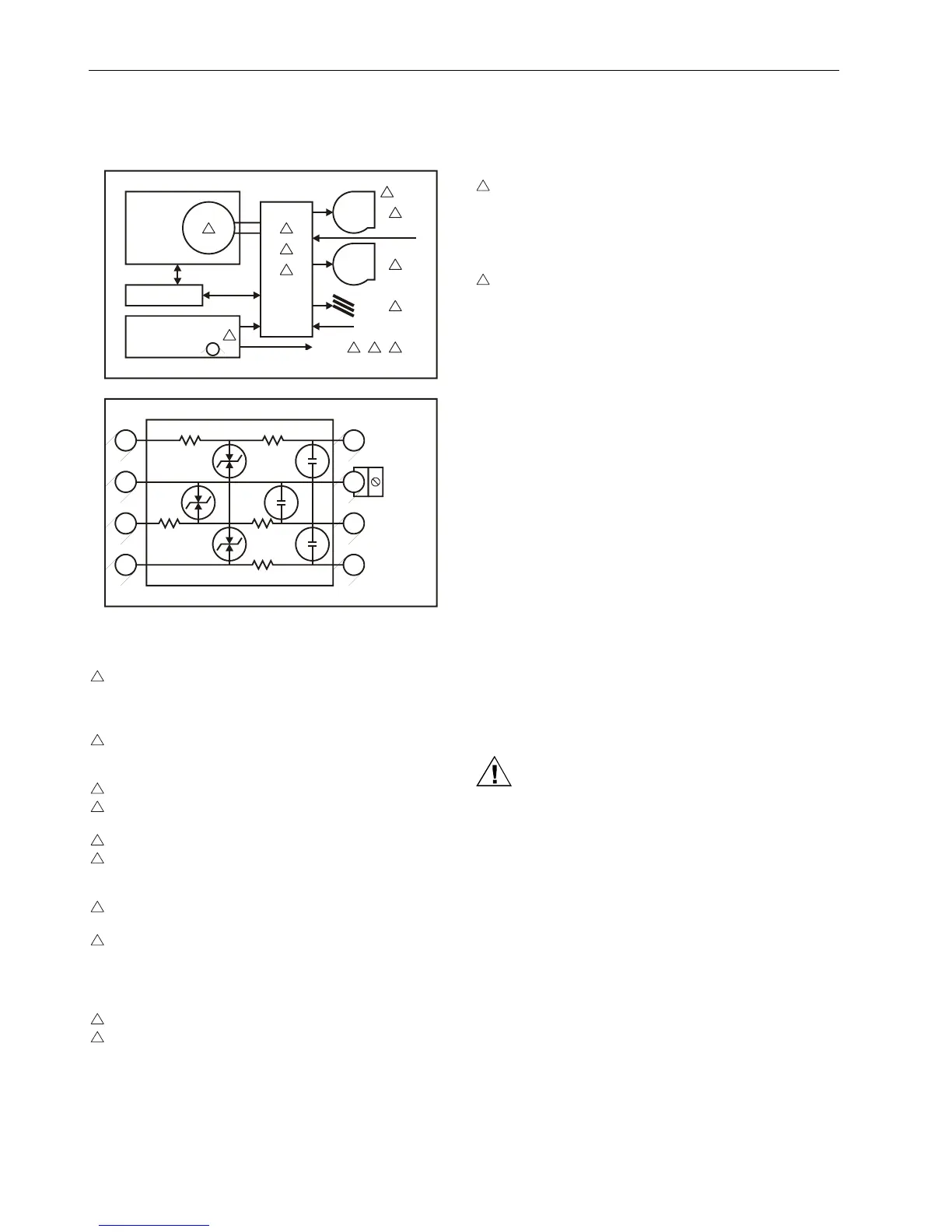

APPENDIX 1: SMOKE CONTROL MODE

Smoke Control Configuration

1

8

11

4

9

5

3

7610

12

2

UL-listed Fire Alarm

Control Unit

Firefighters Smoke

Control Panel (FSCS)

14505068 audible

annunciator

XBS/XBSi/EBI

supply

fan

exhaust

fan

C-BUS

status control

AO

AO

AO

damper

verification

airflow

sensor

Excel 50, 100, 500, 600 Controller or LonWorks I/O

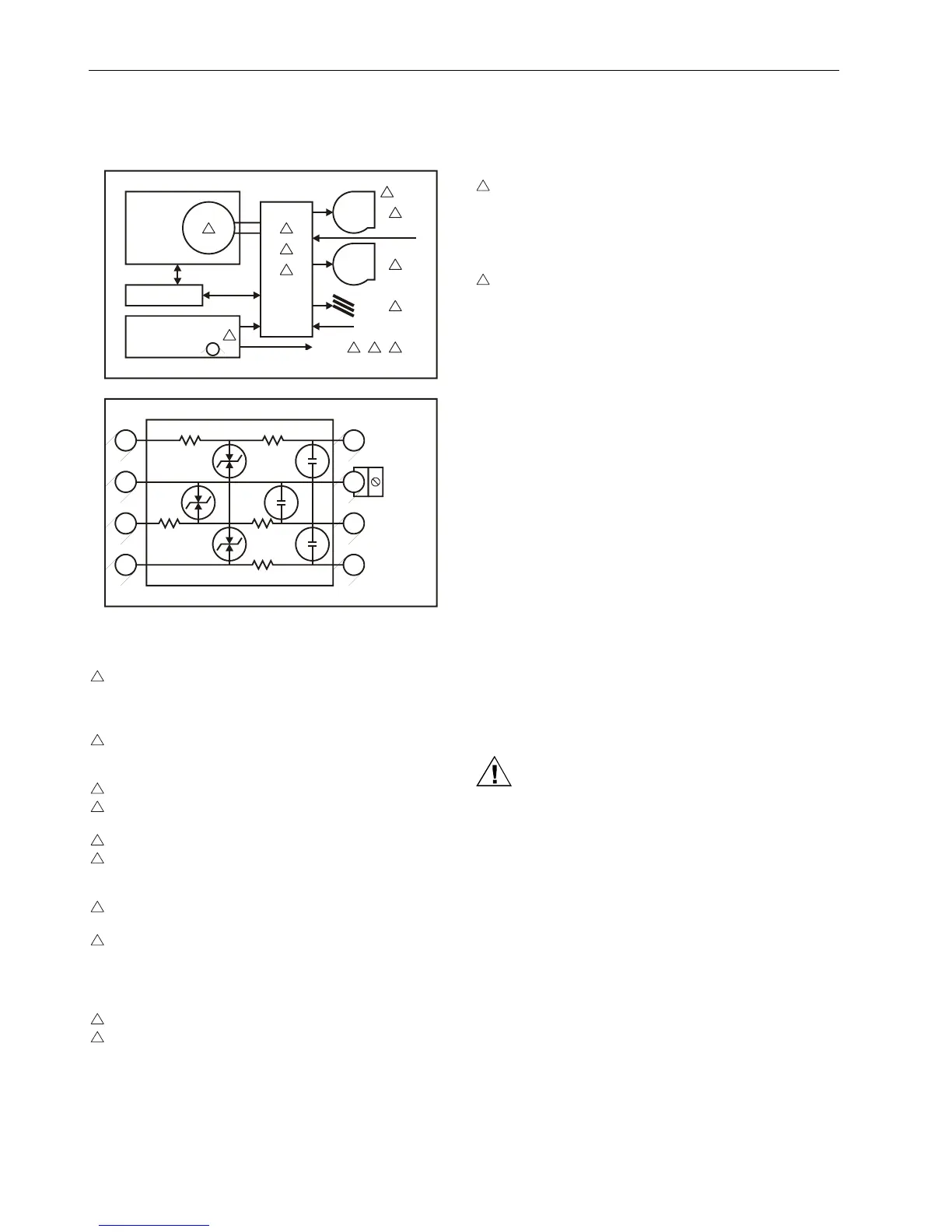

L3

L1

L6

L4 L2

L5

GND

signal line

signal line

common

earth

ground

GND

R6

2.2 ohm

CR6

20V

CR4

75V

CR3

75V

CR1

13V

CR2

10V

CR5

75V

R5

2.2 ohm

R4

2.2 ohm

R2

2.2 ohm

R3

2.2 ohm

W1

schematic diagram of 14502412-010 transient protector

equipment side

Fig. 52. Typical smoke control configuration

NOTES:

1

Locate and configure per NFPA 92A Section 3-4.3.4.

UL-listed annunciator / FSCS panel switches have a

min. rating of 24 V, 0.1 A, and lamps/LEDs have a

rating of 24 V, limited to 50 mA.

2

Locate to minimize control wiring and piping. Avoid

running wires or piping through areas that have a

high fire risk.

3

Locate per UL 555S.

4

Locate separate from and below all building exhaust

fans and upstream of any prevailing winds.

5

Exhaust to outside of building.

6

Locate airflow differential switch per CLEAFS405 and

CLEAFS460 Airflow Differential Switches Installation

Instructions 95-6001.

7

Locate UL-listed damper pressure / position indicator

per damper installation instructions.

8

Smoke control must be initiated by a listed fire alarm

control unit or in zone automatic alarm devices and

not devices located outside of the smoke control

zone interconnecting wiring must be within 20 feet (6

meters) and in conduit.

9

Refer to Smoke Control Fundamentals 77-1134.

10

Verify that the AC voltage source connected to inside

of main line voltage terminal block is from a UL 1481-

listed uninterruptible power supply. The main line

voltage terminal block max. current draw is 0.5 A. For

220/240 Vac (50/60 Hz) applications, verify that no

potential between any conductor and earth ground

exceeds 150 Vac. See Table 14 for 1450 power

supply to be used.

11

All external field wiring must be limited to 3277 feet

(999 meters) and be terminated to 14506944-001

transient protector (35 V, 290 mA max.) except C-

bus field wiring communicating at 1 MHz, which uses

14502412-010 transient protector (19 V, 500 mA. AI

on Excel 50 does not require protector.

12

Distributed LONWORKS I/O (Distributed I/Os) wiring

must be in the same enclosure or less than 20 feet

(6 meters) from the adjacent enclosure. No pro-

tection is required.

Data File Set-Up

Generate the (Excel CARE) data file for the Excel 50 (non-

MMI model), 100, 500, or 600 Controllers. This data file has a

mix of hardware points for the necessary inputs and outputs

to control fans, dampers, and other equipment. In addition to

the inputs and outputs, a customer-control program is written

to control the outputs per the sequence. The Excel 500/600

controllers can reset the program once the data from the

operator interface indicates a normal condition for the

dedicated smoke control equipment. Wire conditions must be

programmed to provide annunciation of trouble conditions.

Also required for a dedicated application for the Excel 50,

500, or 600 Controller is a weekly time program to test control

points, fans, and dampers by exercising the equipment and

verifying feedback automatically during low building activity

periods. The XL 100CUUKL is for non-dedicated smoke

control.

Panel Reset

Wen in the smoke control mode, panel reset is accomplished

by resetting the initiating panel contact circuit or by separating

the initiating/reset switch on the FSCS panel.

CAUTION

Equipment damage hazard.

Failure to use listed/approved replacement parts can

damage the product, degrade operation, and result in

loss of safety function.

This product must be installed and operated within its

environmental, mechanical, and electrical speci-

fications as contained in this document.

When servicing, use only listed/approved replace-

ments parts ordered directly from the manufacturer.

Loading...

Loading...